| | Models by design Tid Tug build...the Big un |  |

|

|

| Author | Message |

|---|

Guest

Guest

|  Subject: Models by design Tid Tug build...the Big un Subject: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:04 am Tue Jan 24, 2017 11:04 am | |

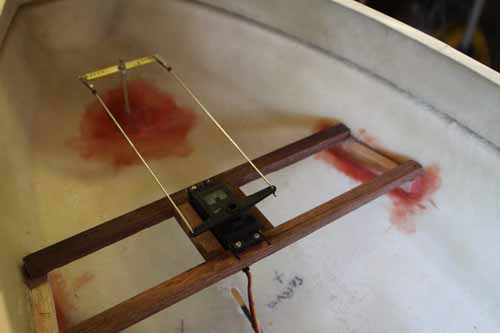

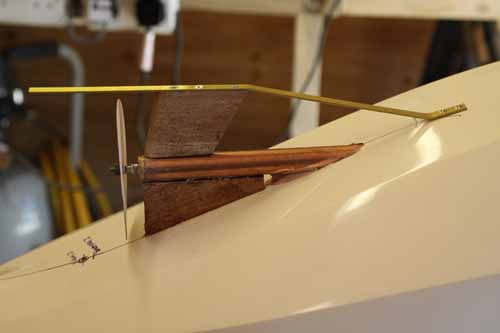

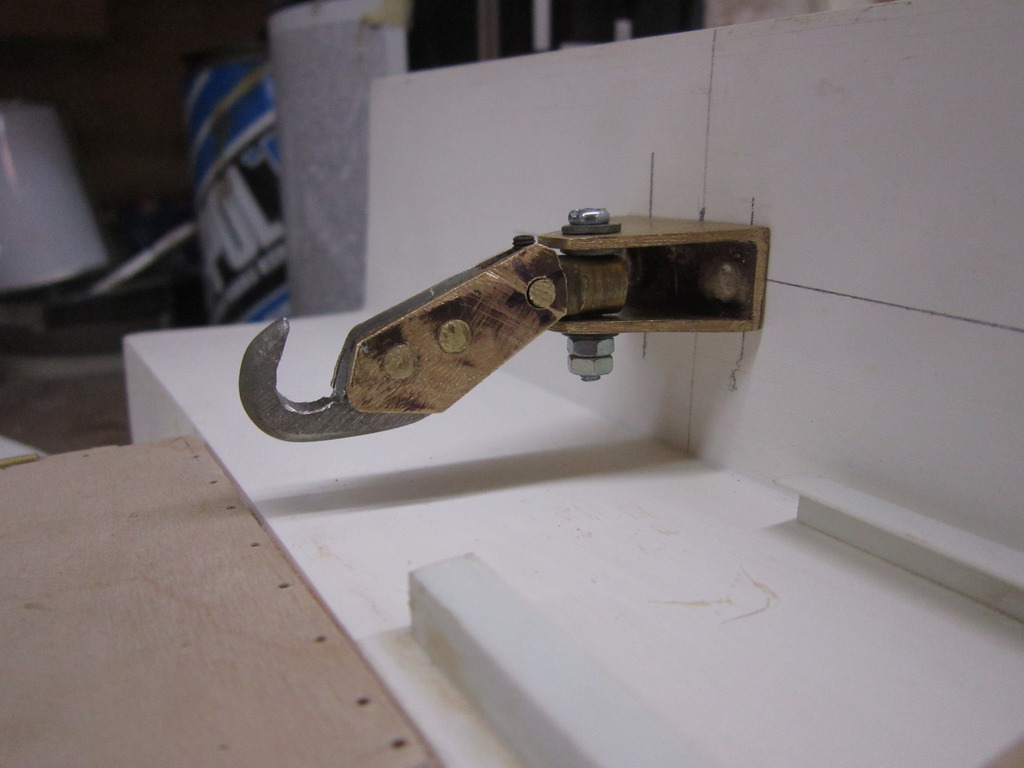

| I was first introduced to the Tid's by now dearly departed next door Neighbour who used to own a Tid Namly a Tid called Bonchurch which was used to take fishing party.s and general Tug towing Based in Bangor North Wales at Penrhyn Port Bangor.I remember it like yesterday having been given the job of cleaning the fresh water tanks and cement washing them ...now a nice job believe you me.The Bonchurch is still on the water albeit now as a House boat and was last seen in Cheshire. Right then the build This is what was done 5 yrs ago and I will bring it up to date after a few disasters along the way. This was the rudder mounting 1st time around...yes it worked [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 003_zps8hzwe1uw.jpg.html]  [/url] Showing the servo arrangement [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 002_zpsh45l2zlj.jpg.html]  [/url] This was the ill fated shaft that has caused all my greif [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 004_zpslqszftlt.jpg.html]  [/url] [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 005_zpsyvadette.jpg.html]  [/url] Showing the Brass Rudder and Shaft plate [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 006_zpslyohsjcs.jpg.html]  [/url] Sorry but this is a rather poor shot of how the deck is held on...The wood pieces you see are bonded to the hull using P40 [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 011_zpskcwpdgqp.jpg.html]  [/url] Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:06 am Tue Jan 24, 2017 11:06 am | |

| The Deck was made in sections which sorry Daz I couldnt remember how I had done it till I found these pics,this from what I can see is made with 2mm ply in more than one section and then it was Bonded to the hull with a couple of layers of 1oz Mat and resin and then tissue applied over it . [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 009_zpstrwngn9x.jpg.html]  [/url] Deck Marked out and ready to cut out using a angle grinder with a thin cutting dicsc [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 016_zpsvbvjf6ie.jpg.html]  [/url] Cut out and ready to be hand sanded to the correct line [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 017_zpsbspgaqfy.jpg.html]  [/url] From this shot you all can see that the superstructure is not level with the deck so has to be cut down to fit level [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 012_zpsyr6vnwag.jpg.html]  [/url] This is how it was done ....a scrap piece of plywood and a pencil cut down and drilled and used as a scribe,now as the deck is smooth it will follow the deck line and put the exact scribe line along where is needed to be cut [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 014_zpsd1b6awkj.jpg.html]  [/url] [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 015_zps7wo2nl7f.jpg.html]  [/url] Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:07 am Tue Jan 24, 2017 11:07 am | |

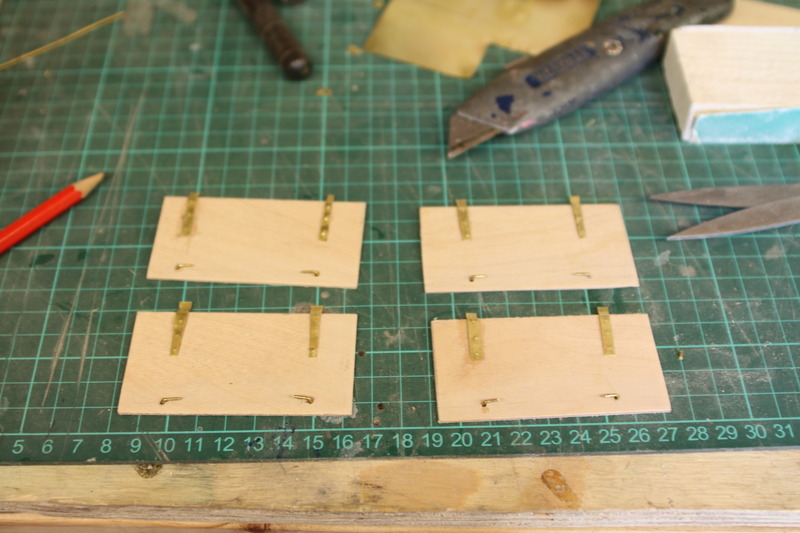

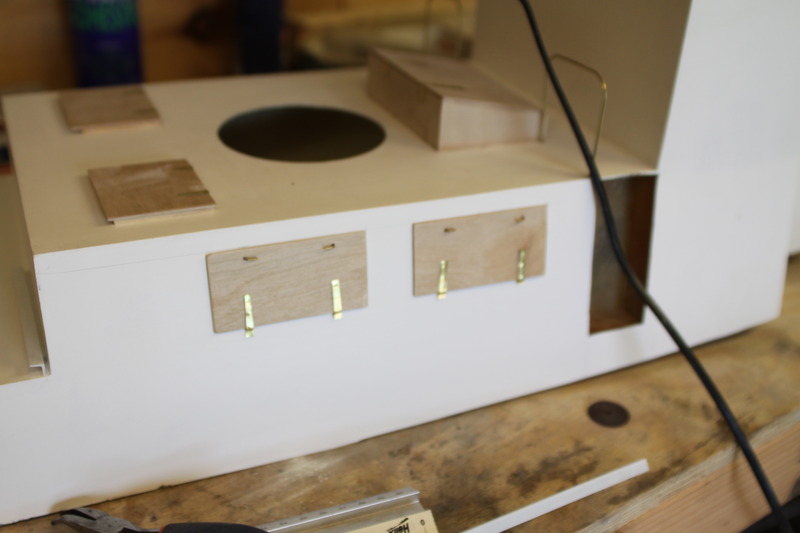

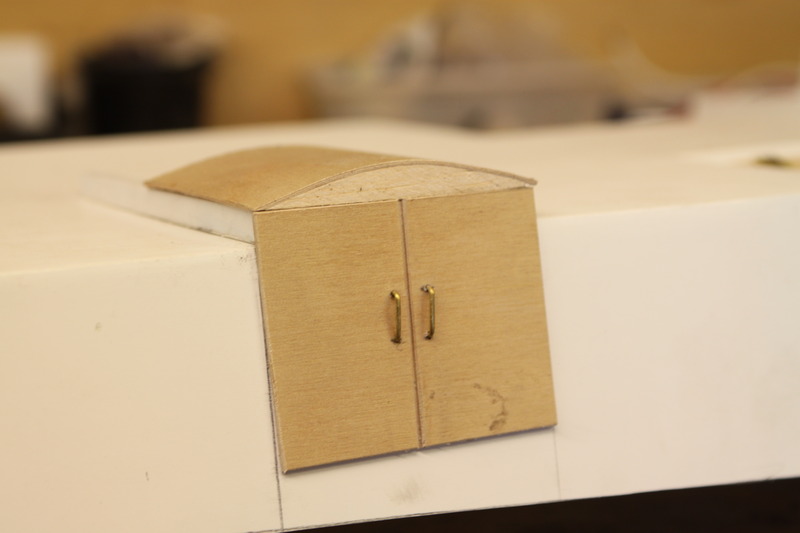

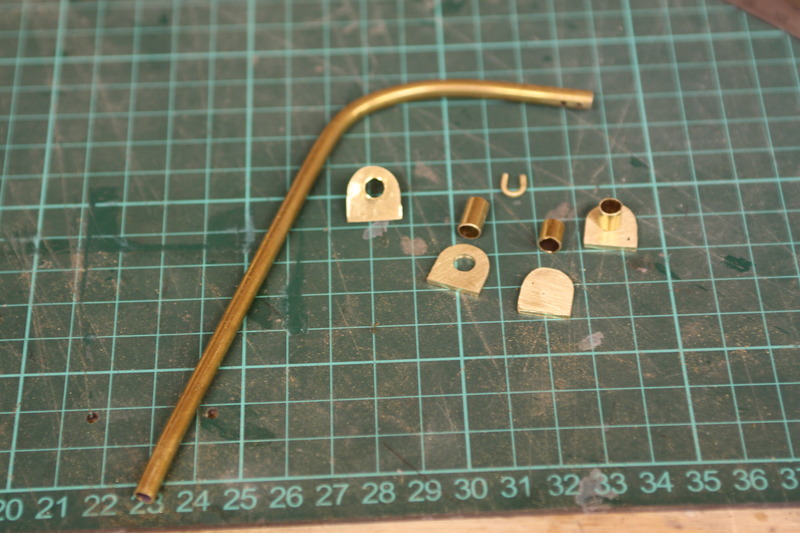

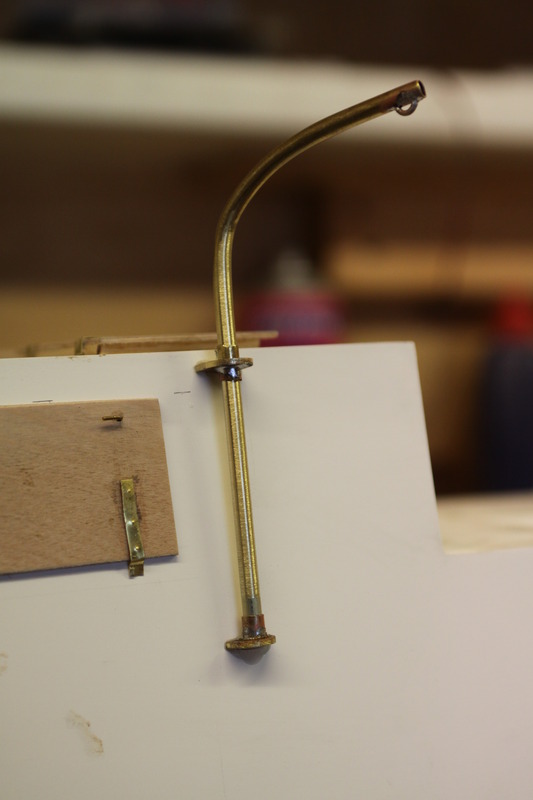

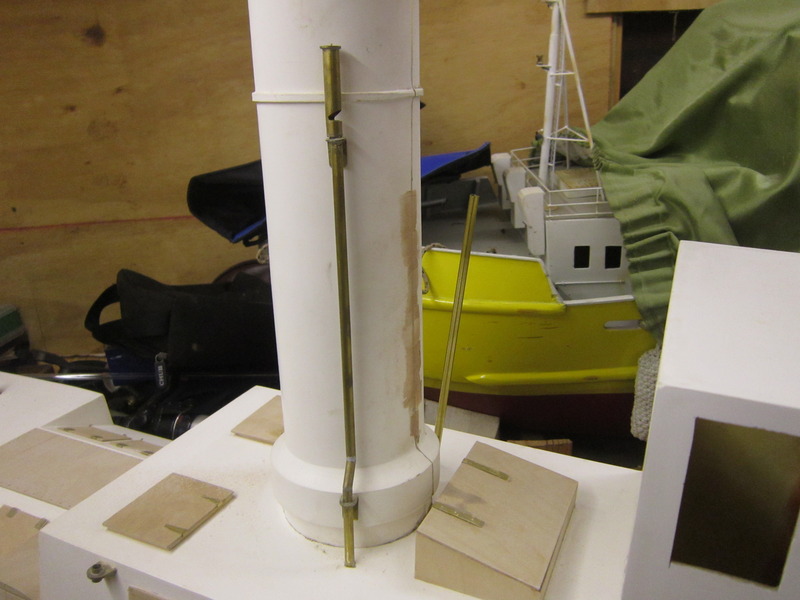

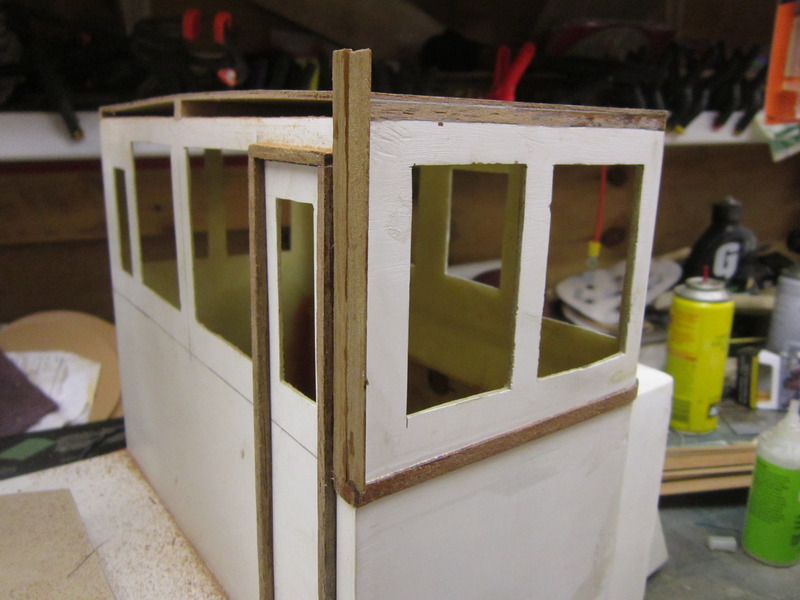

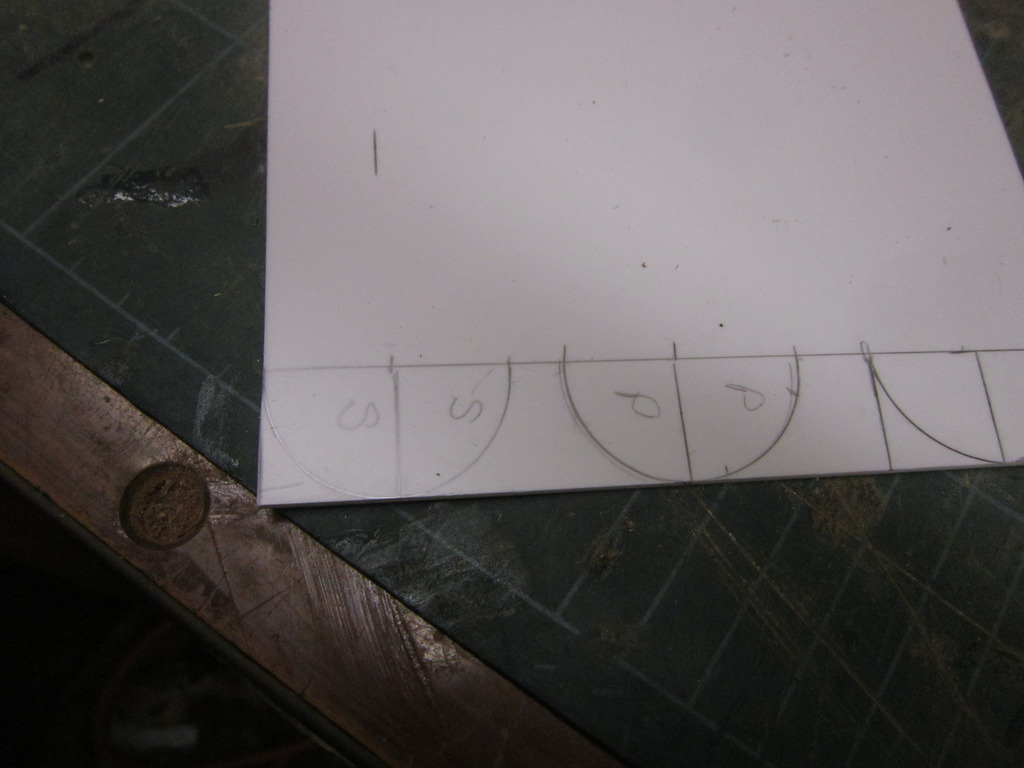

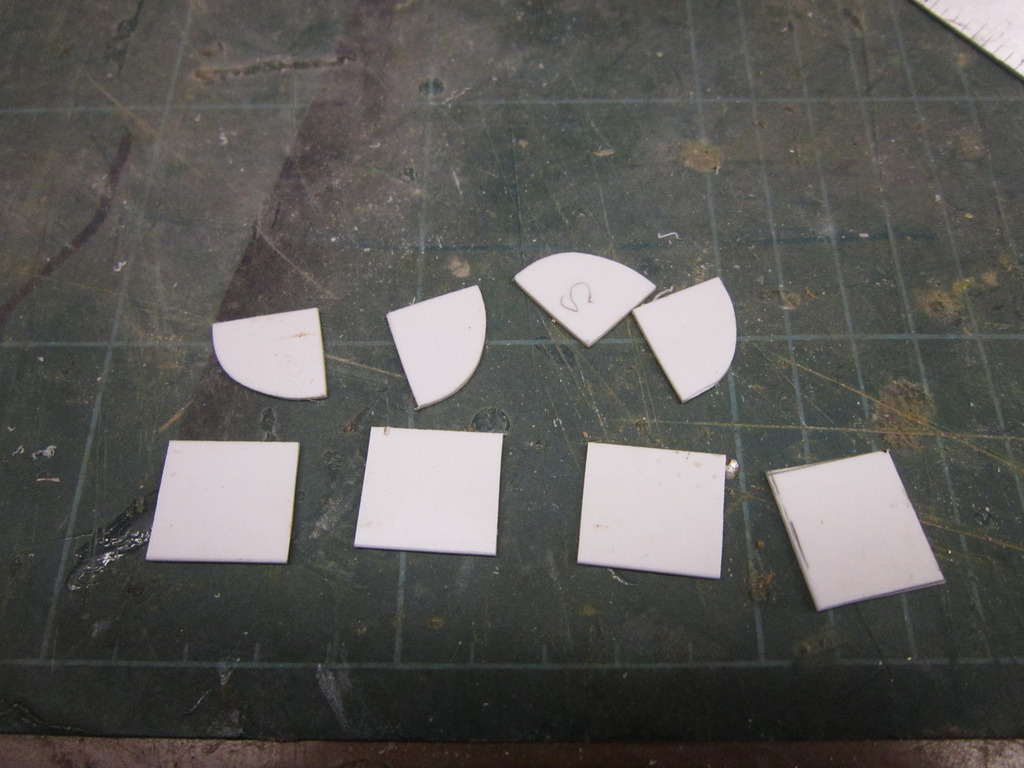

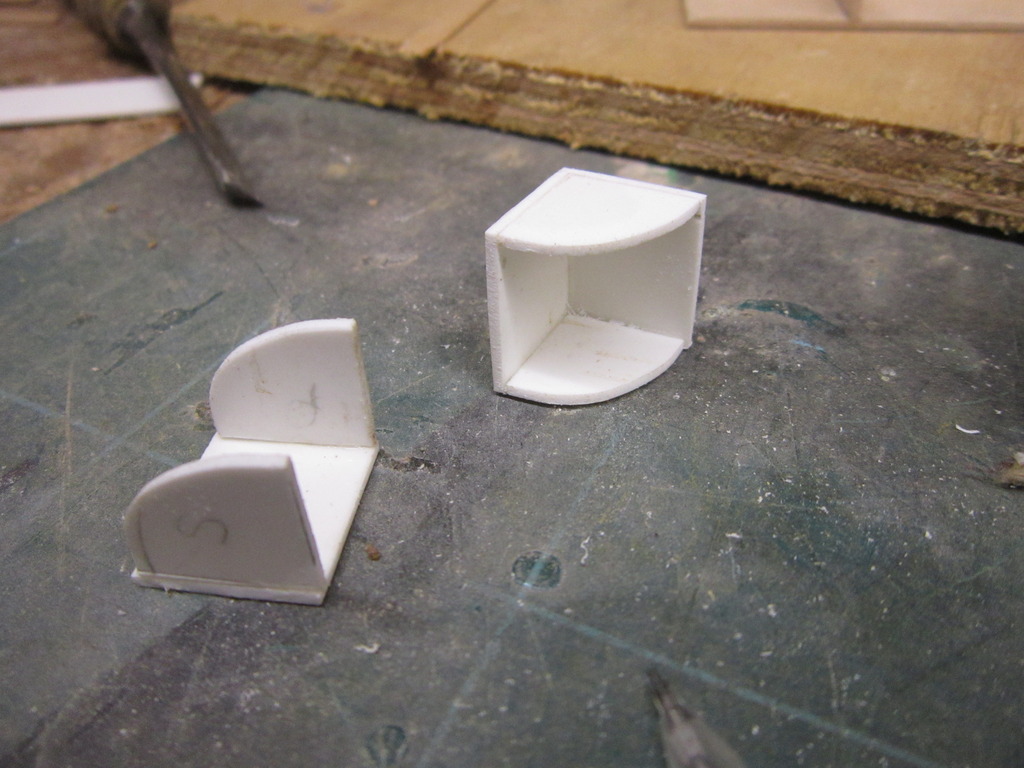

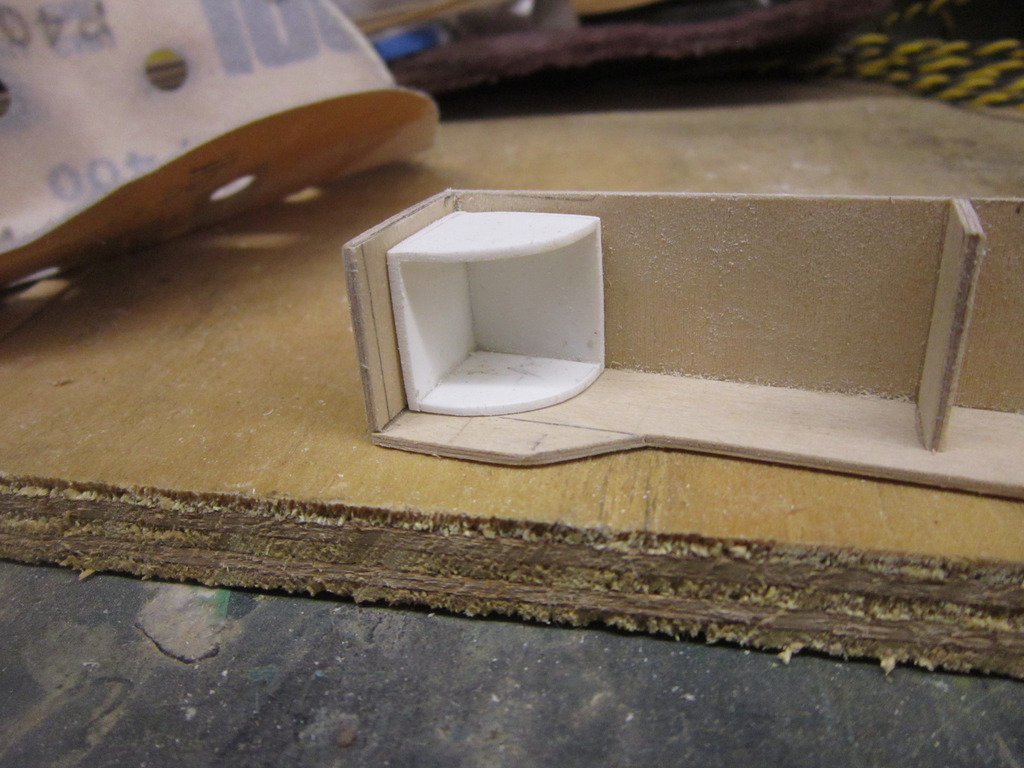

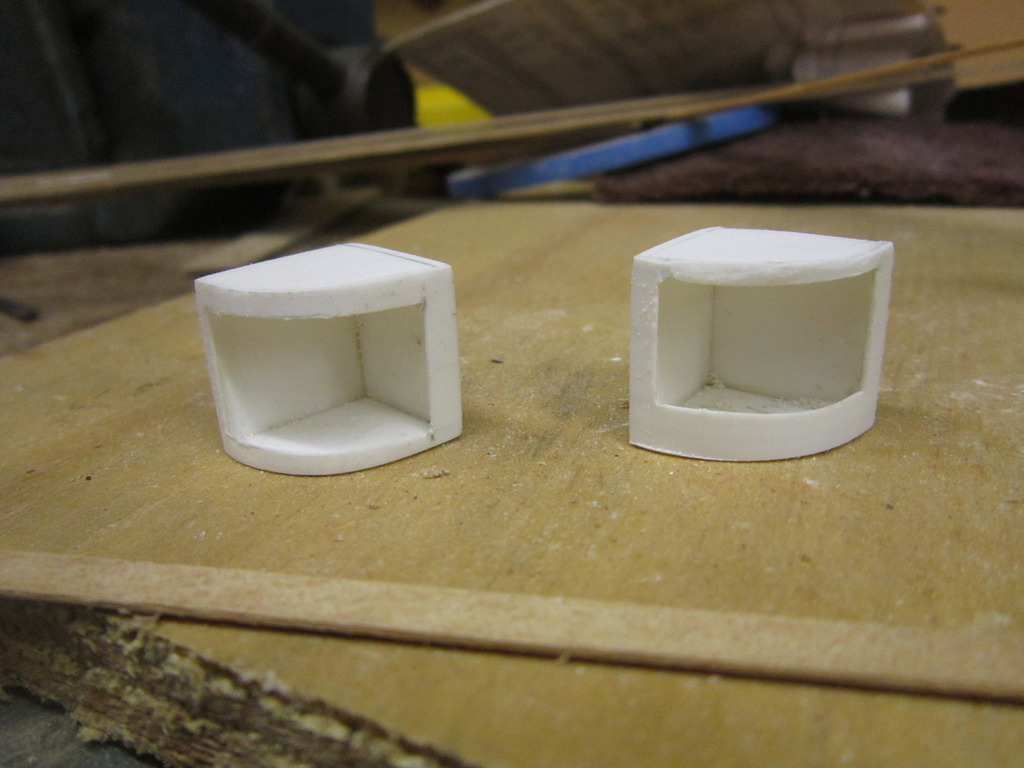

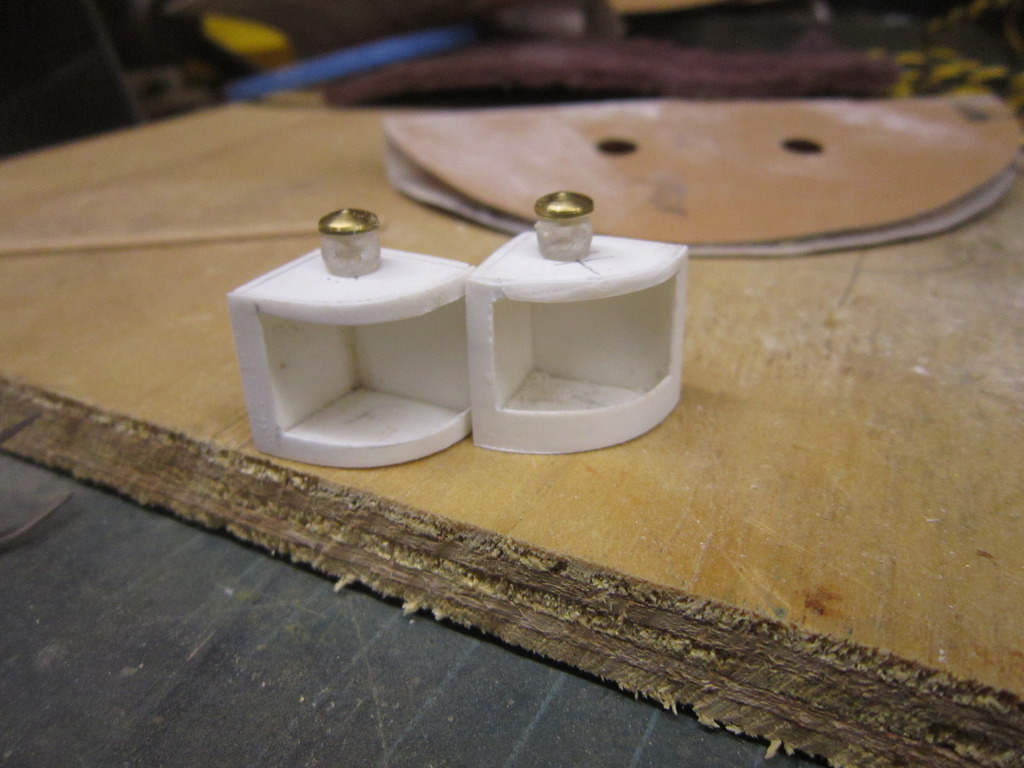

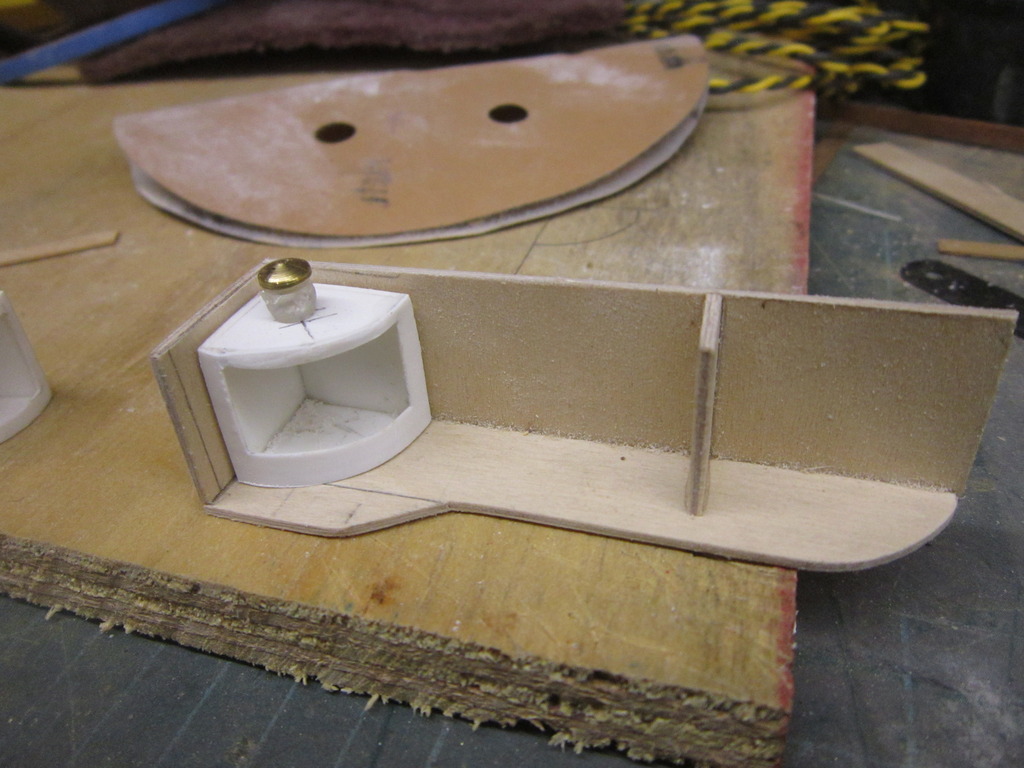

| Some of the superstructure build pics Hatches for the Engine...Made simply form scrap peices of plywood and brass [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 018_zpseacz34qb.jpg.html]  [/url] [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 019_zpszxteav46.jpg.html]  [/url] More Hatches [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 021_zps5ojszkb2.jpg.html]  [/url] [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 023_zpsaetldxzp.jpg.html]  [/url] [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 024_zpsuz0b1wcu.jpg.html]  [/url] Parts of the deck cranes..2 were made [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 026_zps7sd3i3ew.jpg.html]  [/url] [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 027_zpszzb7nwj0.jpg.html]  [/url] The superstructure [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 029_zpsh7qupjbi.jpg.html]  [/url] [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 028_zpspwgjohbt.jpg.html]  [/url] Stern Grating that goes over the exosed steering gear [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 007_zps8l8ui1sm.jpg.html]  [/url] This was simply made from a frame then covered with some planking [url=https://s385.photobucket.com/user/broomsrck/media/Tid TUG 008_zpsr3xd2y8t.jpg.html]  [/url] Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:07 am Tue Jan 24, 2017 11:07 am | |

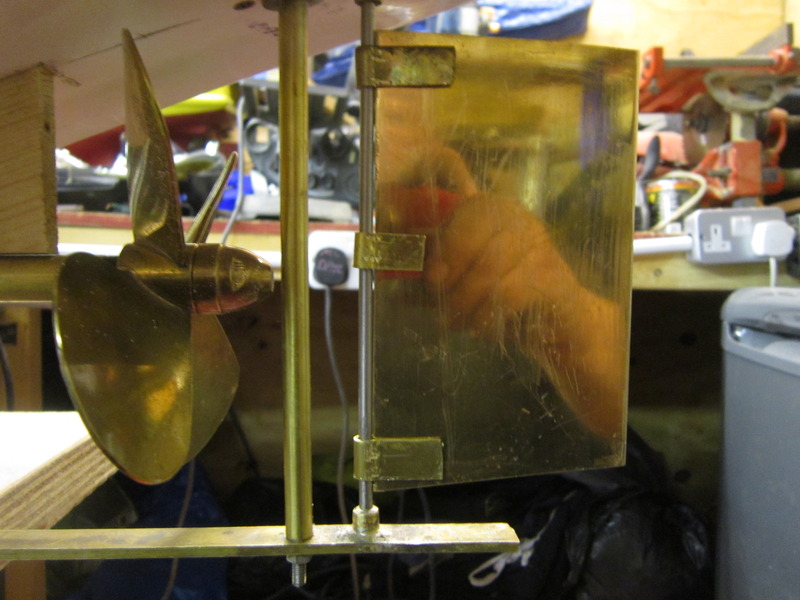

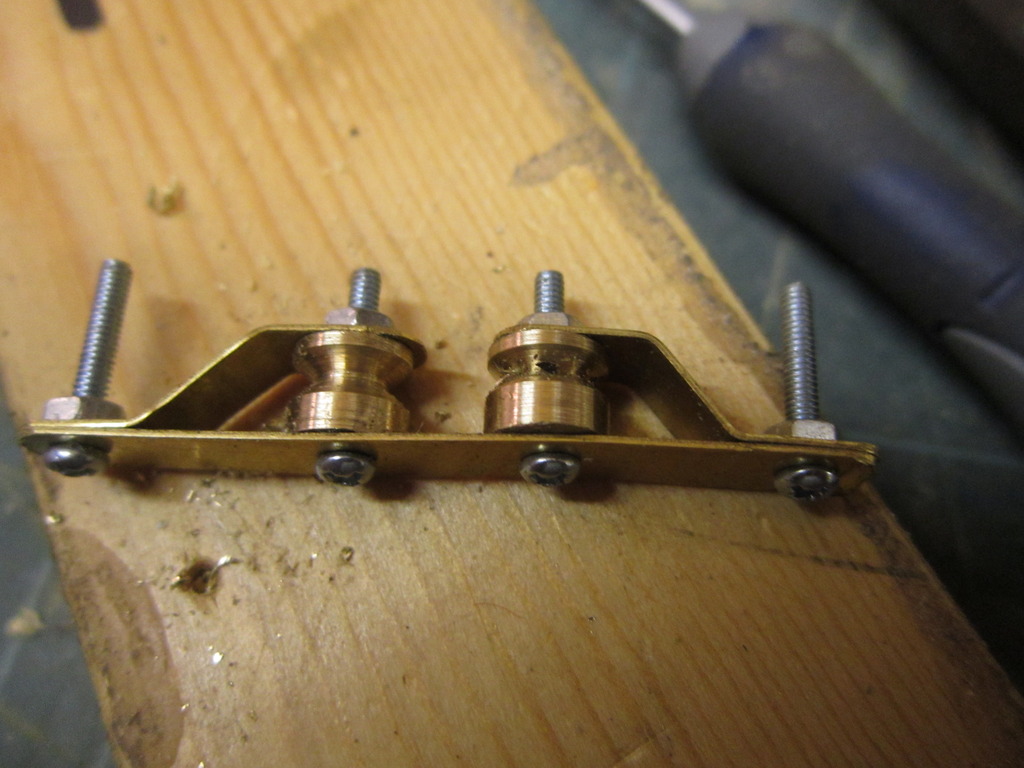

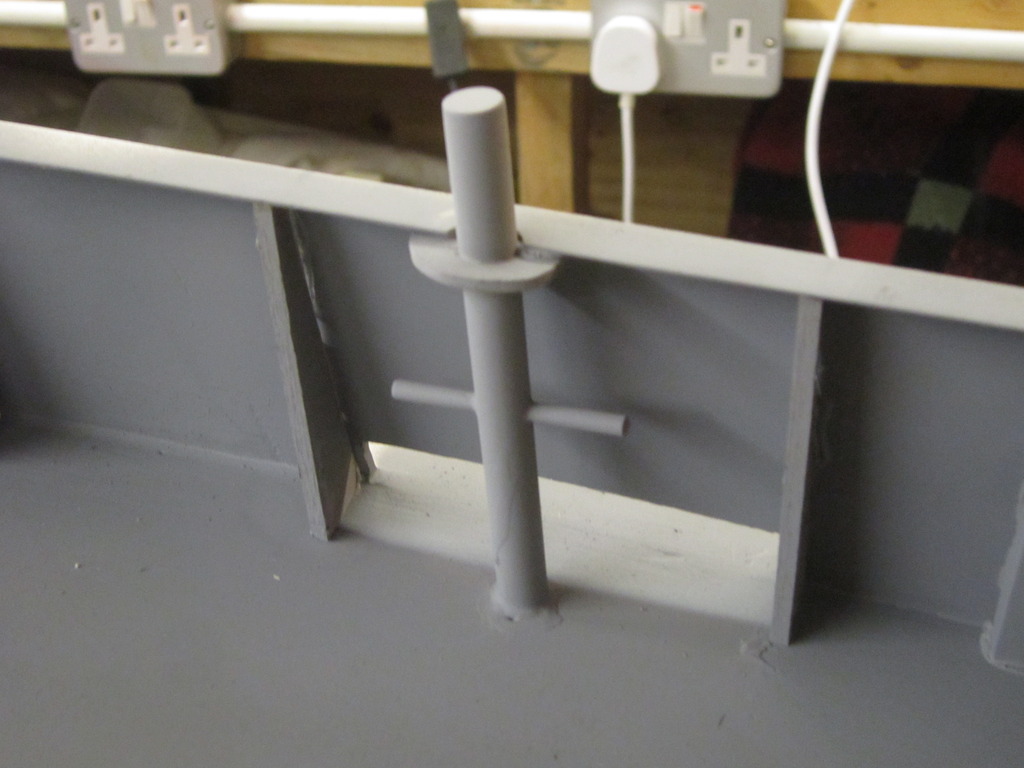

| Right then lets get up to speed on this build. A New shaft was purchased off Steve's Model Boat bits a heavy duty one that is Guaranteed not to bend like the old one...This was simply caused by a golf buggy motor on 24v !!!!...The new one will never bend as it has been built using a 12mm stainless steel inner turned down to a 6mm end and the same for the prop. Propshaft is being supported by a scrap piece of wood bonded to the hull with P40.This as you can all see is held down wth some brass bent over to help stabeise the shaft and prevent shaft oscilation  This pic shows the new shaft arrangement and also the rudder Shaft bearer,you will see that the upermost Support has already been Attatched to the hull this was done by simply drilling the wood that has been shaped and glueing in the bolts using 2 part epoxy and P40,the lower part still has to be made...the brass strap that is at present seen in the pic will be removed when the lower part is made But a new one will be put form top to bottom to sanwich the shaft to the rudder/Shaft strengtheners.  This is the lower rudder shaft bearing that has been Silver soldered to the brass lower keel of the Rudder.  Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:10 am Tue Jan 24, 2017 11:10 am | |

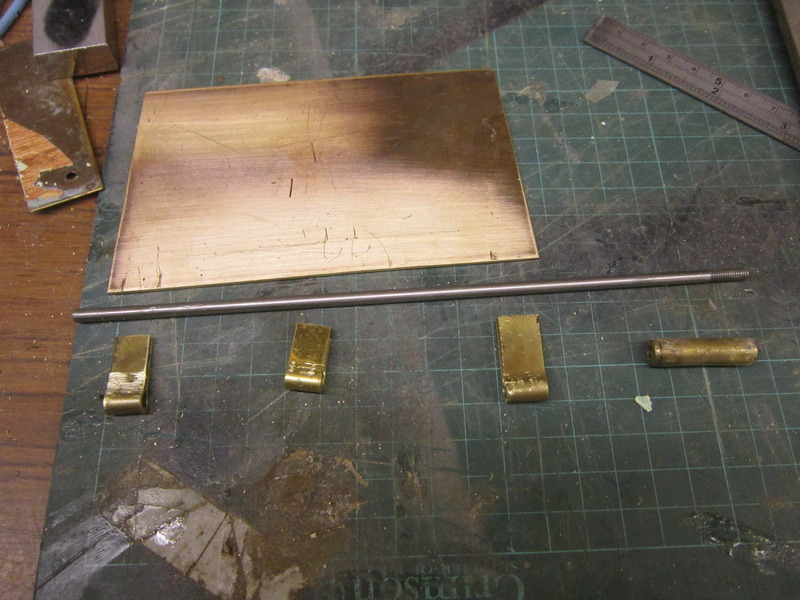

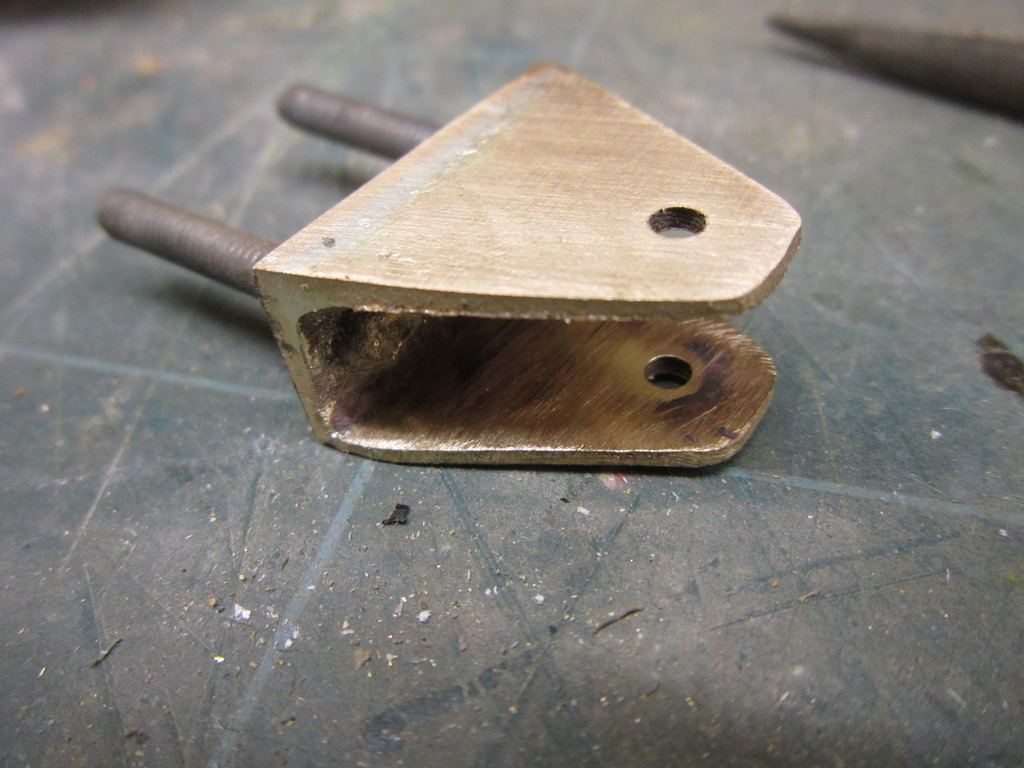

| Right then sorry if the pics are slightly out of sequence ...but it seems I did not take any more pics of the build so I am trying to play catch up Pic of Deck to superstructure coaming.The was done simply by screwing through the deck to some 1x1inch pine and then simply glueing and screwing the Coaming to it....this still needs to be tidy'ed up.  Picture of the Water Tank....the bolt heads have ben made by using the heads of ordinarry dress maker pins  Dummy steam whislte fitted to oneside of the Funnel,as you can see the other is work in Progress  Rear Towing Bollard,this was made by drilling some Brass tube and simply insering another through it...This was soldered with a 100watt soldering iron and ordinary solder  4 mooring posts...yet again a simple affair cross drilled tube and Soldered  Mast detail  This pic shows how tight it is for access at the stern once the deck is fitted and with me having such large hands beleive you me is not much fun  So the rudder build starts in earnest,Right this is a shot of the top rudder shaft bearing,simply constructed by cutting down a M4 shafted propshaft,This has a total lenght of approx 40mm,If you decide to do this you will need to cut the shaft accuratly an straight...easy to acheieve with a tube cutter,the baering is so so easy to get out ...simply use a drift and tap out,and yes you guessed it tap it into the new shaft  The Rudder components,This consits of a shaft,Main rudder plate...made using an old Door finger plate,3 shaft to rudder hindges.The hindges were made using brass strip cut to length and simply using a vice and a hammer to shape them,These of course will be silver soldered and not ordinary solder as this would simply be not strong enough  The rudder trial fitted to the hull.....There is still work to be done to the hindges cleaning and trueing them up before they will be Silver soldered to the shaft  Dave |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:15 am Tue Jan 24, 2017 11:15 am | |

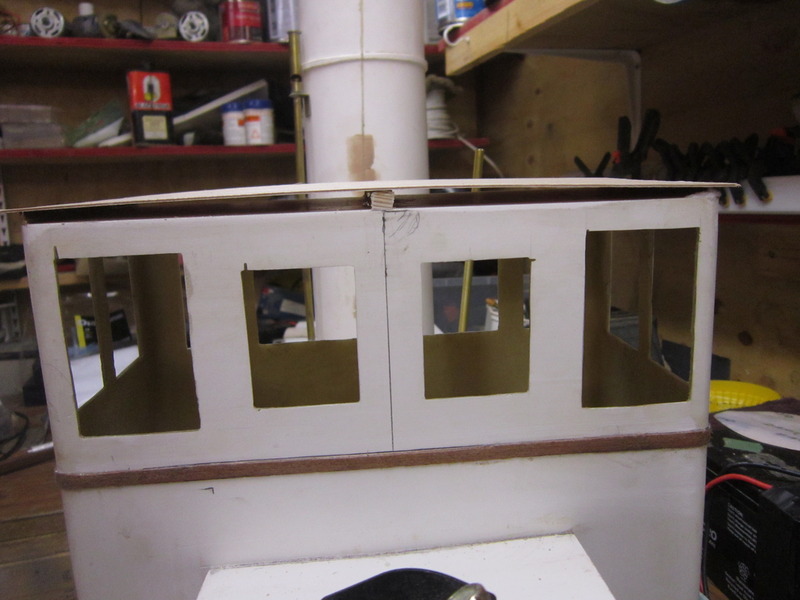

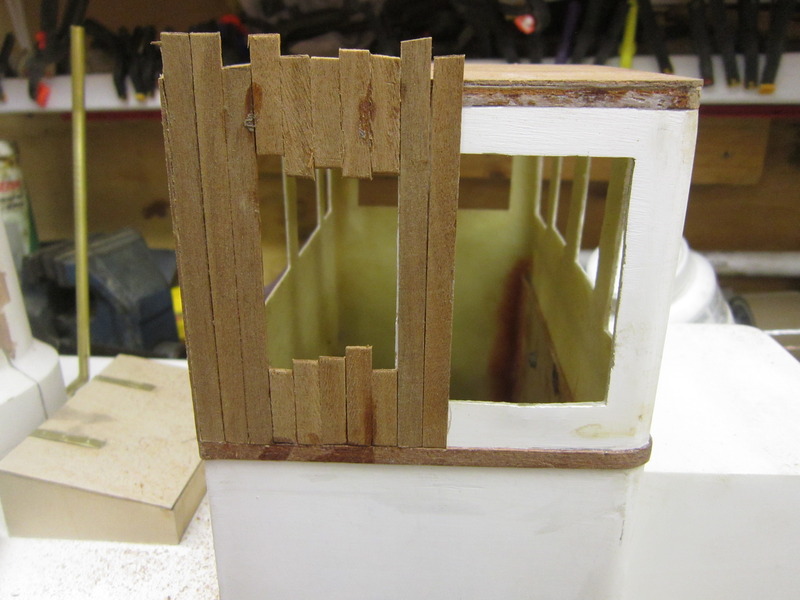

| Well after yeasterday's Fiasco of getting thing totally wrong and throwing around 5 flippin bullwark templates cos Dave got it wrong and then to cap it all I got the steps totally wrong I just wondered what could possibly go wrong tonight....So I decided to start on the woodwork on the bridge...what could possibly go wrong !!!!!! 1st job was to Mark all around where the wood was to go and also the door to the Bridge  Right then as you all can see there is a radius around the bridge so we have 2 options available to us,either fill the radius out so you have a 90 degree corner....well that would be cheating and an easy way out..OR bend the wood round the corner.Anyone who has tried to bend wood cold knows what happens it splits,so what can we do...Well there is only one course of action left.Steam it or soak it in water...the wood I am using is 1/32 thick planks...To Be honest with you I am not a great beleiver in getting wood soaking wet.....But as I did work in a boat yard and had to bend teak planks around the deck edge by means of a steamer. Now how can we steam wood...you either make a proper enclosed steamer or you simply get the old camping stove and a kettle out......You simply boil the kettle and leave it on the boil so it produces steam,Now for heavens sake BE CAREFUL when doing this as you can get SERIOUSLY HURT if you do not be careful......If you get hurt after this article I WILL NOT BE HELD RESPONSIBLE. The plank needs to be steamed for a couple of mins till it becomes soft now the trickk here is to work fast and carefully...clamping as you go and not to be too greedy...if it does'nt feel right STOP and resteam(MM DAVE why didnt you),do one side at a time ...wait 5 mins then simply do the other side,if when you remove the clamps the first side straightens up simply resteam it clamp up and pull gently round the other side. I will confess one little thing here I did make a right pigs ear of this and had to scrap 4 before I got it right...I can obviously use these bits to do the planking so all is not lost Steaming in progress  1st side bent  2nd Side   This will now be left to dry overnight and it will retain its shape and will be glued to the superstructure with Zap superglue. And before anyone picks up that the wood is not straight on the bridge front...I know and Ive been out to the shed to correct this so it will be ready for tomorrow !!!!! Whilst this was drying I started on the rear of the Bridge so a door frame was made using 1/8 mahogany strips,ready to be planked,All around the bridge will have to be individually planked right up to the roof. Now here lies a bit of a problem as the roof of the bridge is square and it should have a radius on it...This I will show you how to do at the next installment Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:16 am Tue Jan 24, 2017 11:16 am | |

| Right then Proof of the pudding so to speak....after 24 hours the wood has dried out and has retained it's shape after steaming  Now glued to the bridge  Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:16 am Tue Jan 24, 2017 11:16 am | |

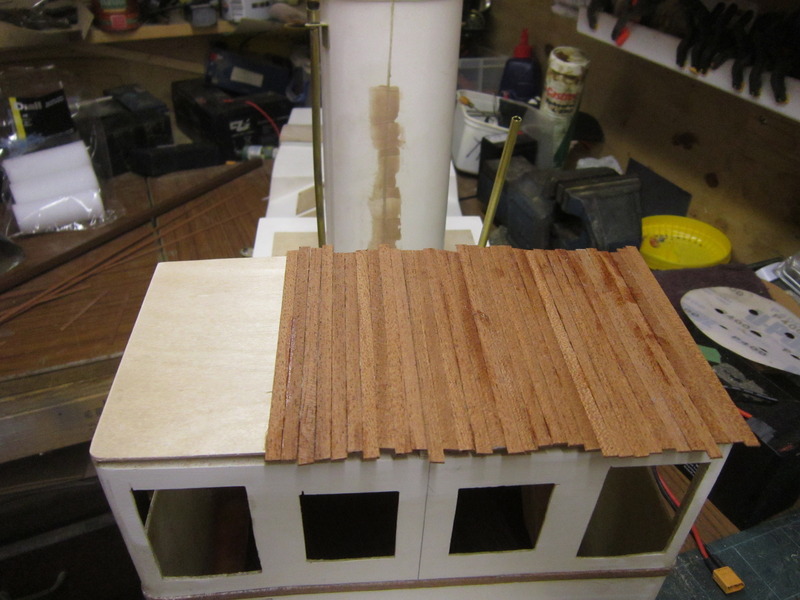

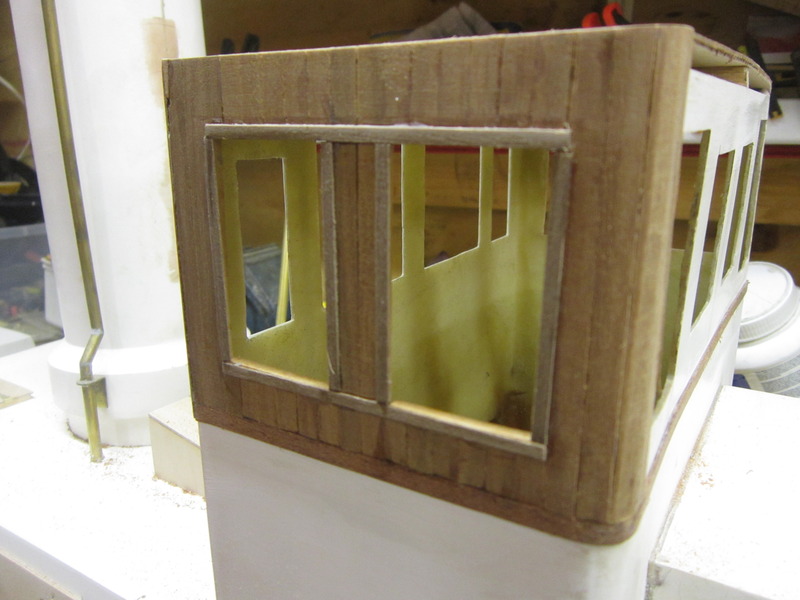

| Right then lets get the roof of the bridge planked,right then we really need to sort out the camber of the roof so the center was Marked out and a piece of scrap wood was used around 8mm x8mm and a couple of 4x4's were used on the edge of the roof,this allowed a decent roof camber  A piece of ply was then glued to these so I could plank it over and a center line was marked so I could start form the middle and work outwards  Around 40 were needed for the roof alone  I was initially going to use Pva Waterproof wood glue but changed my mind as I couldnt wait to get it done so Opted for Gorrilla Glue the Gell one...must admit this is spot on so so easy to use and I didnt even stick my fingers together and is waterproof as well  This is the roof around 3/4 done  Roof Done..But you will see that the planks are higldy pigldy so to speak and need to be rubbed down to the wodth and length of the plywood roof,How do we do that may you well ask...well very simply really...I made a rubbing down block by simply glueing a peice of 80 grit sandpaper with spray glue to a block of wood..I also made one of 180 grit and 400  Here you will see that i have started the vertical planks that go around the bridge are  This was done in a similar way to the roof But a dremel was used to get a rough shape and then a simply filed to finish  As there are windows around the bridge a window frame is needed I will show you how to do this on the next instalment   Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:17 am Tue Jan 24, 2017 11:17 am | |

| Right then Window frames....the Stav way...whether this is the correct way lord only knows but is has worked for me and thats all that counts . Firstly i glued the inner part of the window frame to cover up the edge of the fiberglass....yes it is far to oversize but it is easily sanded with a block.  This is showing the frame sanded down  Then a simple frame of much narrower planks were glued to the outside to cover everything up...simple but in my mind effective  Now me being the impatient fellow decided I would try out the woodstain that I purchased in B&Q just so I could see what it was like  Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:18 am Tue Jan 24, 2017 11:18 am | |

| Wey hey managed to get a full day in the shed today so I actually managed to finish the cladding of hte bridge and make all the window frames.....phew thank goodness that's over and done with. It was then given 3 coats of light oak stain...more like dark oak !!! But to be honest with you I wanted it dark as all the Tid's were this way   I now had to construct the Port and Starboard Navigation light Boards which I will now endevour to build some lamps for it...unless of course I can get hold of some 1/12th scale old fashioned ones  This is being held up to see what it looked like as it will need painting before it gets glued on to the bridge  Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:19 am Tue Jan 24, 2017 11:19 am | |

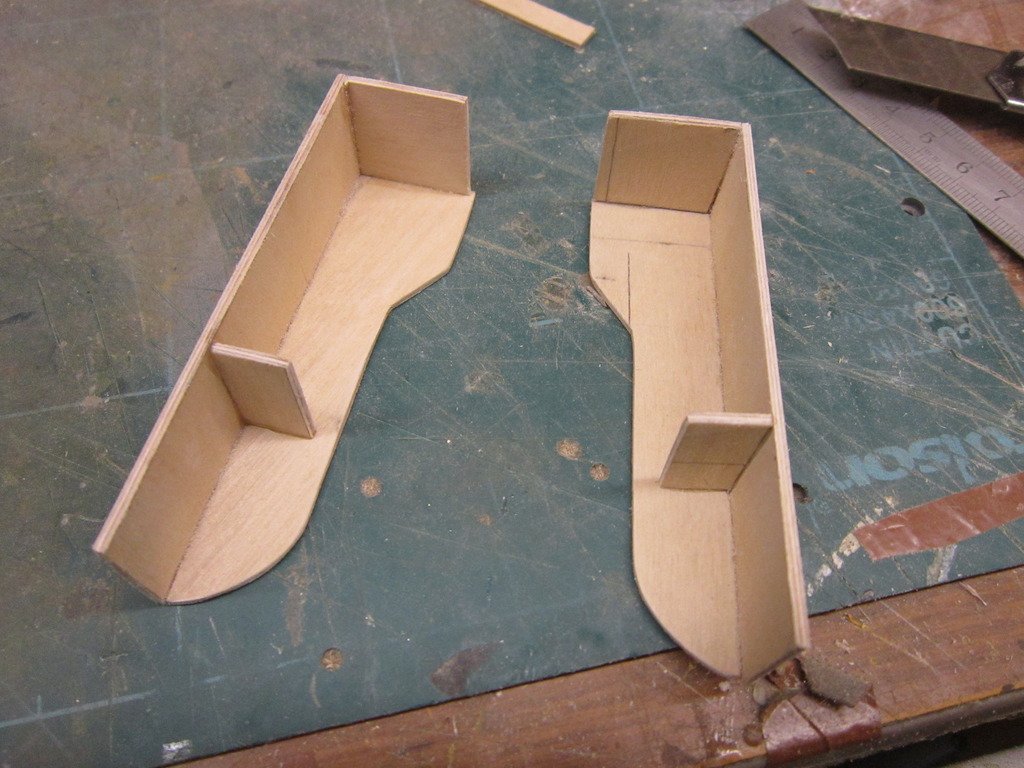

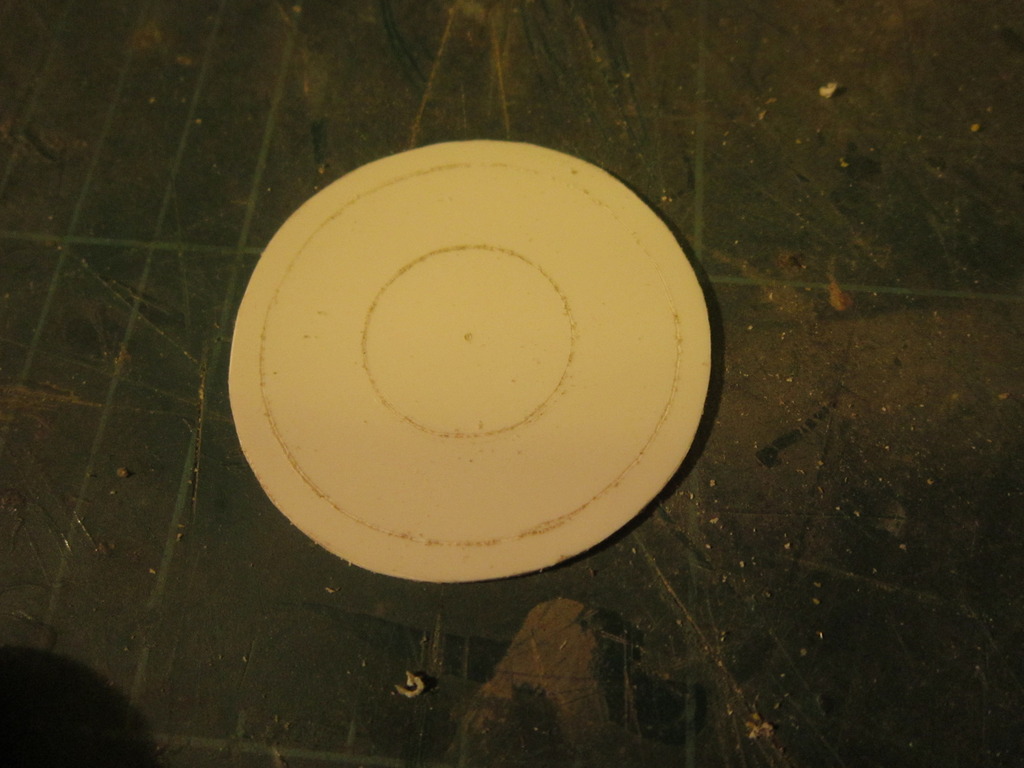

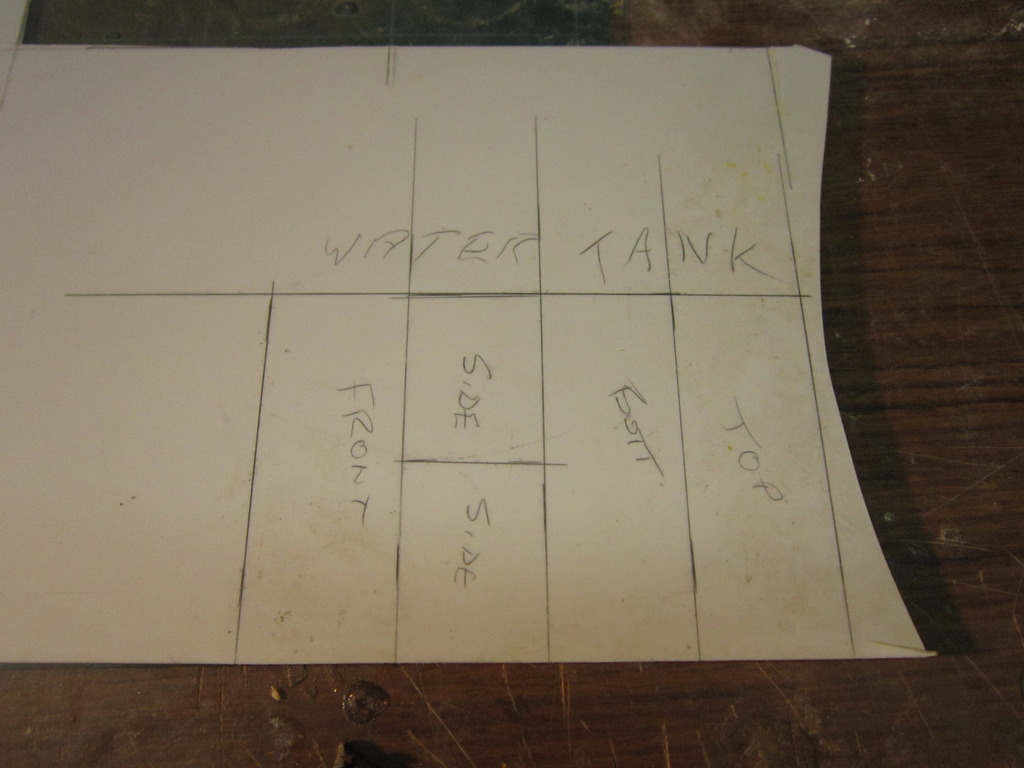

| All marked up ready to cut  All the bits ready to be glued together  One nearly finished the other is being constructed  Trial fit  Front of lamp with a slot cut in it for the light  Tops pf the lamp were made with components of some brass lamps which I had spare  trial fit in its new home  Coaling scuttles made ready to be fitted  These were scribed to simulate the ridges on them  fresh water tank all marked up on Plastic card ready to be cut and assembled  Dave Report to Moderator  84.92.112.90 84.92.112.90 |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:20 am Tue Jan 24, 2017 11:20 am | |

| Pic of steps from the deck to the superstructure  Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Jan 24, 2017 11:20 am Tue Jan 24, 2017 11:20 am | |

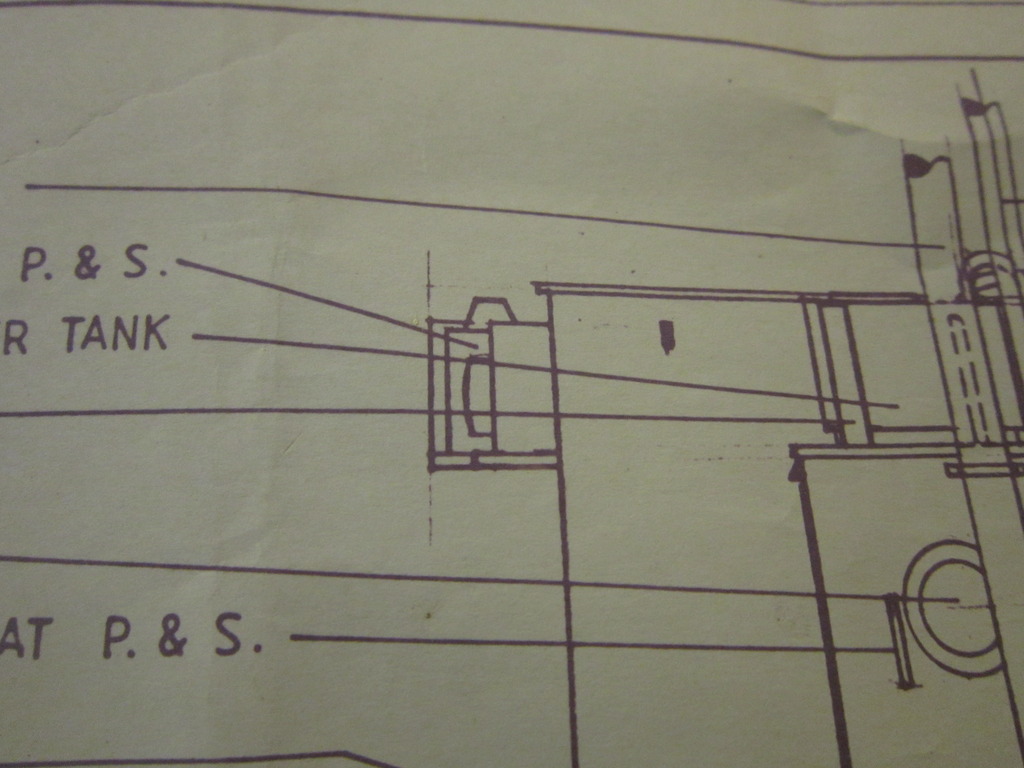

| Pic of the Port/stbd lights on the plan clearly showing the front light board  Now unless this was a war requirement to partly sheild the lights...lord knows why it was there Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Thu Jan 26, 2017 11:19 pm Thu Jan 26, 2017 11:19 pm | |

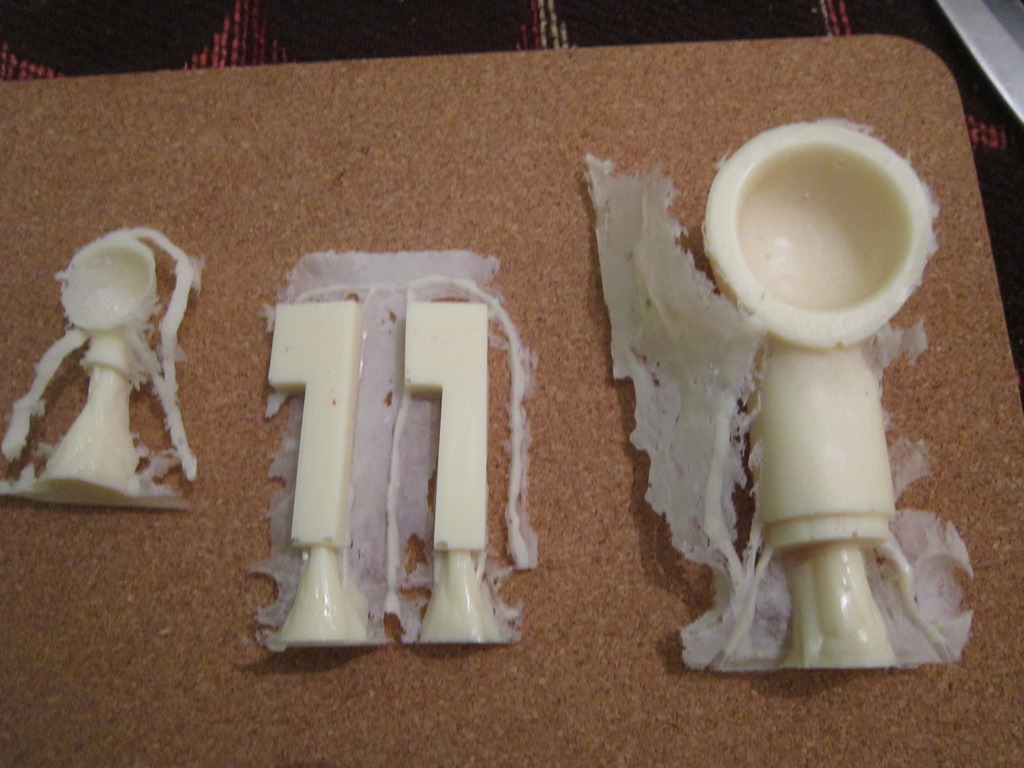

| Right a bit of an update on this build.........A couple of the deck vents have been built to be used as plugs so they can be cast in resin....main reason for this is there are 14 of the little blighters on the Tid all down the sides of the hull.They will be used to make rubber moulds ready for the resin casting,Also a technical drawing was made in 1/12th scale of the rather large cowl vents . Now a rather large confession here...not knowing a thing about making rudder moulds let alone my skills are simply not good enough to make some cowl vents of that size I simply asked a god friend of mine HOW do it do this and what do I need to get to make the rubber moulds etc etc....his ONLY answer to me was ...send the vents and a drawing up to me and ill make you the moulds and you can make the resin bits...............That Friend was Neil Howard Pritchard no less,to say I was gosmacked was an understatement....... NEIL can I publically THANK YOU for this Dave  Report to Moderator Report to Moderator  84.92.112.90 84.92.112.90 |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Fri Jan 27, 2017 12:34 am Fri Jan 27, 2017 12:34 am | |

| how have I missed this build matey........superb. I sent 3 to jim so he could post em on mayhem..........but my phone won't download the others so will post them later today.............bit worse for wear from booze tonight.

an old friend of mine out walking home with his wife in Fleetwood 3 nights ago after a birthday drink for her........was mown down by a drunk hit and run driver who mounted the pavement.........he was killed almost instantly........we were only chatting on Facebook just before Christmas....so am not chatting on the phone at the mo , too upset to chat personally.

neil. |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sat Jan 28, 2017 9:53 am Sat Jan 28, 2017 9:53 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sat Jan 28, 2017 11:20 pm Sat Jan 28, 2017 11:20 pm | |

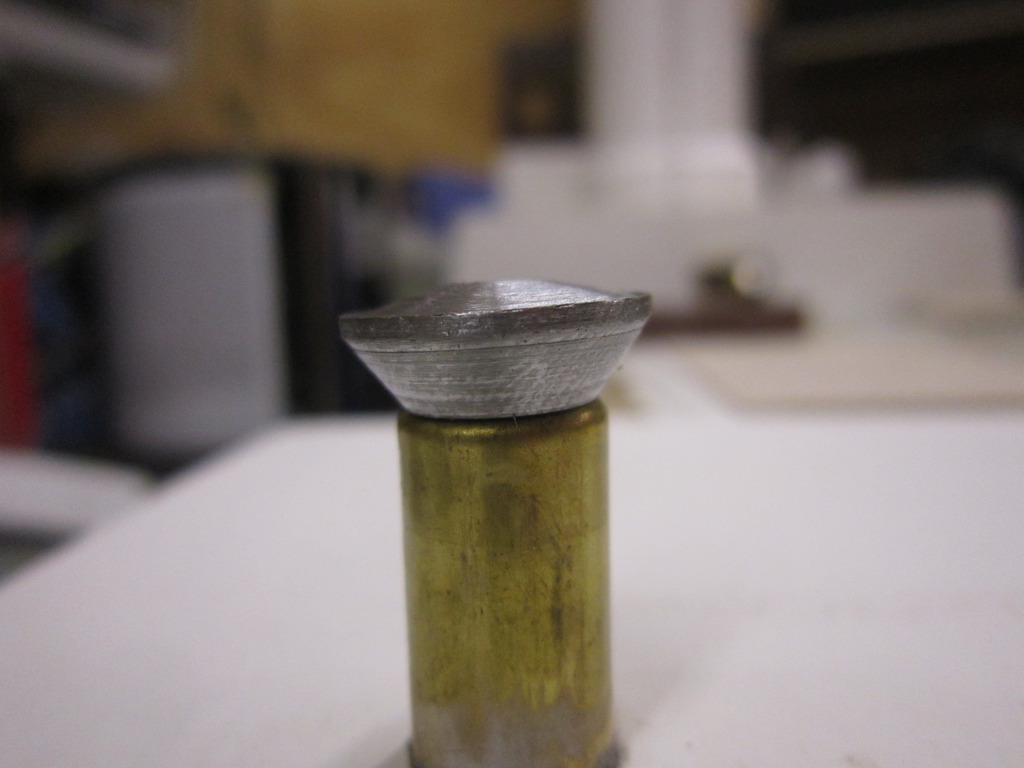

| Right then onwards and upwards as they say...Today's tasks were pretty time consuming to say the least and made me really think what I was up to. First job was to do some work on the lathe to true it up and thanks to a gent form Bethesda who just was just going for a walk past my house made that job a doddle....Thanks Billy. With the lathe running true it was time for Dave to do some turning....What do I know about this subject...well Ill be honest with you all....Naff all.....I honestly ain't got a clue what I am doing so it was rather trial and error,trust me on this. I managed to turn 4 small pulleys for the Roller fairleads and believe you me they ain't to bad...well I would say that !!! These were drilled and then the frame was made up with some brass strip....I only manged one as I ran out ...don't ask  One of the completed rollers  Next on the list of many jobs was the towing hook...........I decided to scrap the Mobile Marines one that I has(SORRY BRIAN) and canabalise it as I wanted a hook that not only went from side to side but up and down as well. 1st little problem with this was the gimbal on the one I had was to big by 5mm so into the lathe it went and was turned down...the actual hook was filed out to gain a bigger throat,new side cheecks were made and the actual hook bracket was made and silver soldered and 2 bolts were also soldered so it could be attatched to the superstrucre ...there is of course a spreader plate inside the superstructre.      There was one little job that I have been putting off as I had not got a clue how to do it till today....Ah ha I said Lathe,this was the cap on the Galley stove,it needed a Chinaman's hat on it so this was duly turned down and made.     The observant amongst us will notice that at the moment that there are no holes to allow the smoke to get out of the chinamans hat this will be rectified tomorrow. Dave  |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sun Jan 29, 2017 9:38 am Sun Jan 29, 2017 9:38 am | |

| | |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sun Jan 29, 2017 8:49 pm Sun Jan 29, 2017 8:49 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sun Jan 29, 2017 11:23 pm Sun Jan 29, 2017 11:23 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Mon Jan 30, 2017 12:09 am Mon Jan 30, 2017 12:09 am | |

| did well tonight guys.......got both halves of the rubber moulds done, and contrary to reports that i'm suffering dementia I remembered to put a coat of Vaseline on the first half as a release agent before I laid the 2nd half.............now who am I making them for please..........do own up,

neil. |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Mon Jan 30, 2017 12:16 am Mon Jan 30, 2017 12:16 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Mon Jan 30, 2017 9:47 am Mon Jan 30, 2017 9:47 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sun Feb 05, 2017 5:31 pm Sun Feb 05, 2017 5:31 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Mon Feb 06, 2017 1:56 am Mon Feb 06, 2017 1:56 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Mon Feb 06, 2017 2:20 pm Mon Feb 06, 2017 2:20 pm | |

| Well this stuff arrived this afternoon........think I might just have to have a play later on afterMrsStav comeshome and relieves me from childminding duties  Dave  |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Mon Feb 06, 2017 2:50 pm Mon Feb 06, 2017 2:50 pm | |

| see ya got the good stuff matey.

with that you'll be able to take a sharp craft knife and pare out the inside of the large cowl vent to a thinner wall to make it look much more realistic with a thinner "wall", as the polyurethane can be carved for a good length of time before it hardens to a harder state. |

|

| |

Tug--Kenny

Lost But Never Forgotten R.I.P

Posts : 284

Join date : 2011-06-11

Age : 82

Location : Newport, South Wales,UK

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Mon Feb 06, 2017 8:28 pm Mon Feb 06, 2017 8:28 pm | |

| Worth knowing. Thanks for the tip  ken | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Feb 07, 2017 8:51 am Tue Feb 07, 2017 8:51 am | |

| That stuff looks like fun, I want to have a go, is this the best stuff to start with? I looked before and found it daunting with the amount of products available.

Where did you get it from please ? | |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Feb 07, 2017 11:38 am Tue Feb 07, 2017 11:38 am | |

| - troutrunner wrote:

- That stuff looks like fun, I want to have a go, is this the best stuff to start with? I looked before and found it daunting with the amount of products available.

Where did you get it from please ? hi troutrunner, It all depends on how fast you can work.....this is quick set polyurethane resin, which as I said earlier won't snap shatter or break and is carvable if you want to trim it down, as opposed to polyester resin which shatters and snaps and has no residual strength.it also has very low shrinkage problems. Also if you have a lot of castings to do of larger items, you can get through a lot in a day, lol On the down side it starts going off within a couple of minutes from mixing and within 3 minutes it is unusable because it is almost like rubber before it finally sets and starts to cure. you also have to be very accurate with the 50/50 mix or it won't set.i use a set of digital scales in grams to get my mix right, and the big problem is, after first opening the two tins you have about 3 months shelf life on it before any future mix comes out like honeycomb crunchie bars......just a mass of bubbles..plus if you don't have a lot to cast........expensive........those two tins that I recommended to stav cost with postage around 23 quid I reckon, maybe more. CFS is the company.....google it and look at the range of products. http://www.cfsnet.co.uk/ neil. |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Feb 07, 2017 6:29 pm Tue Feb 07, 2017 6:29 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Wed Feb 08, 2017 9:20 pm Wed Feb 08, 2017 9:20 pm | |

| Well here we are the pics of the casting. To be honest I was very lucky in that the aerosol tops were a perfect amount to fill all the moulds up in one mix....begginers luck without a doubt  Waiting for the resin to cure  Wey hey it has worked   I made up 4 mixes last night  I will be casting another 4 mixes up today of the small Gnv vents,obviously all the vents are going to need cleaning up this is a simple process of rubbing down with some 240 grit. Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Thu Feb 09, 2017 7:22 am Thu Feb 09, 2017 7:22 am | |

| |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Thu Feb 09, 2017 8:00 am Thu Feb 09, 2017 8:00 am | |

| Nice one Dave, they look good  Neil, thanks very much for the info  | |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sat Feb 18, 2017 9:13 pm Sat Feb 18, 2017 9:13 pm | |

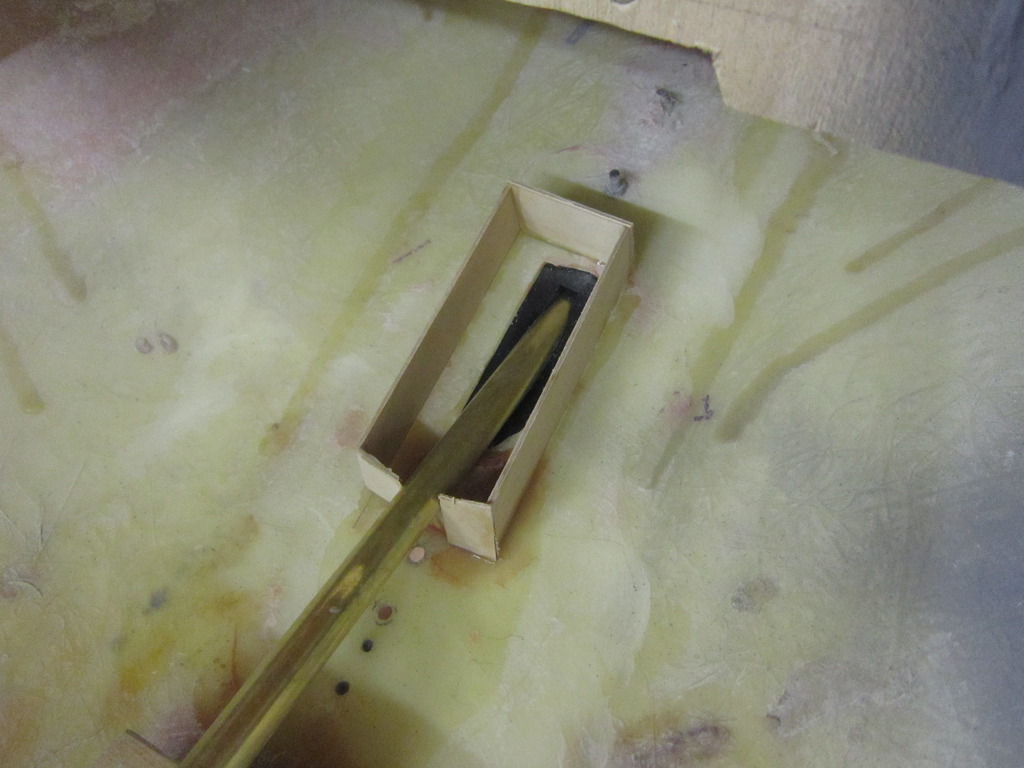

| On wards and upwards so they say so on we go.....the job in hand this weekend was to not only get the Propshaft in the hull but get the rudder installed and a Platform made for the rudder servo and electrics First job was to get the rudder and support post epoxied in so a box was made and epoxy was poured into it  The Propshaft was taped up underneath to stop the P40 just dropping through the hole...Insulating tape was used for this  Yet again a little box was made up of scrap plywood to make sure a block of P40 formed around the shaft...also the shaft support had P40 also applied to it   The Shaft bottom support was made using some pine and through screwed to the rudder skeg,and also supported by means of some brass strip  Dave  |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sat Feb 18, 2017 10:33 pm Sat Feb 18, 2017 10:33 pm | |

| that is some construction Dave........I've less support in my roof space..................good to see some nice fitting out inside, unlike the sheds that I throw inside my models............I should be ashamed.

great stuff, keep it up. |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sat Feb 18, 2017 11:00 pm Sat Feb 18, 2017 11:00 pm | |

| There is method in my Madness Neil...I am rather hoping that I can fasten the superstructure to the Rear wood for towing obviously glueing another peice of 20x20 to the one that has been screwed on...the one nearest the stern.

Oh and Ive had an EUREKA moment....I am going to wrap the motor in cling film and coat it in vaseline....Make a tough for it to sit in .... and pour in the casting reisn and hey presto a motor mounting.....sound so so easy...I do HOPE IT IS

Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sun Feb 19, 2017 5:42 pm Sun Feb 19, 2017 5:42 pm | |

| Well an engine mounting had to be made...I already knew I needed a gap of 5mm between the bottom of the motor to the hull so this was drawn on the plywood as the bott line of the side cheeks of the mount. I used a plastic shape finder(cant remember it's name) to get a rough idea of What I wanted and then divided the dia of the Motor in half so I could use a compass to scribe what I had to cut out   Now I built up a casting box so I could pour the resin into   Testing it was the correct height  Obviously if I simply just poured resin into this all I would get is a oblong box...so the Motor was wrapped up in insulating tape and Vaseline was rubbed all over it and also the casting box,This was done to stop everything sticking together and also to get the Mounting out of the casting box.  The white stuff is simply Sticks like the proverbial...this was used to stop any of the resin escaping out between the motor and the casting box  |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sun Feb 19, 2017 5:43 pm Sun Feb 19, 2017 5:43 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Sun Feb 19, 2017 11:31 pm Sun Feb 19, 2017 11:31 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Tue Feb 28, 2017 9:10 pm Tue Feb 28, 2017 9:10 pm | |

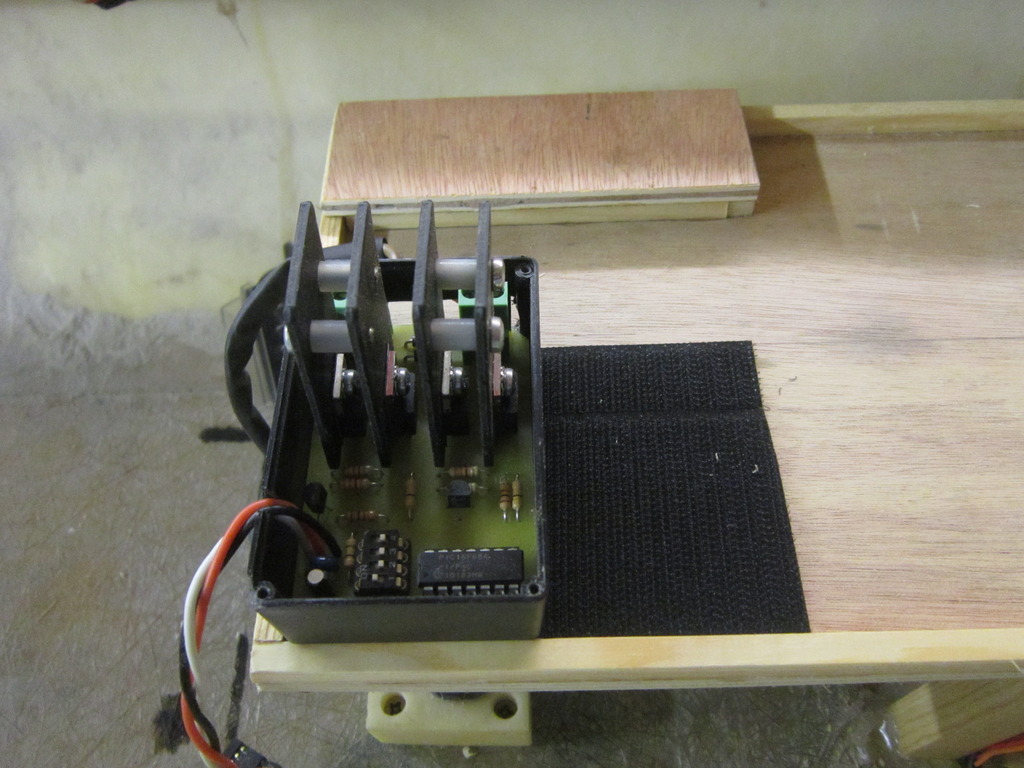

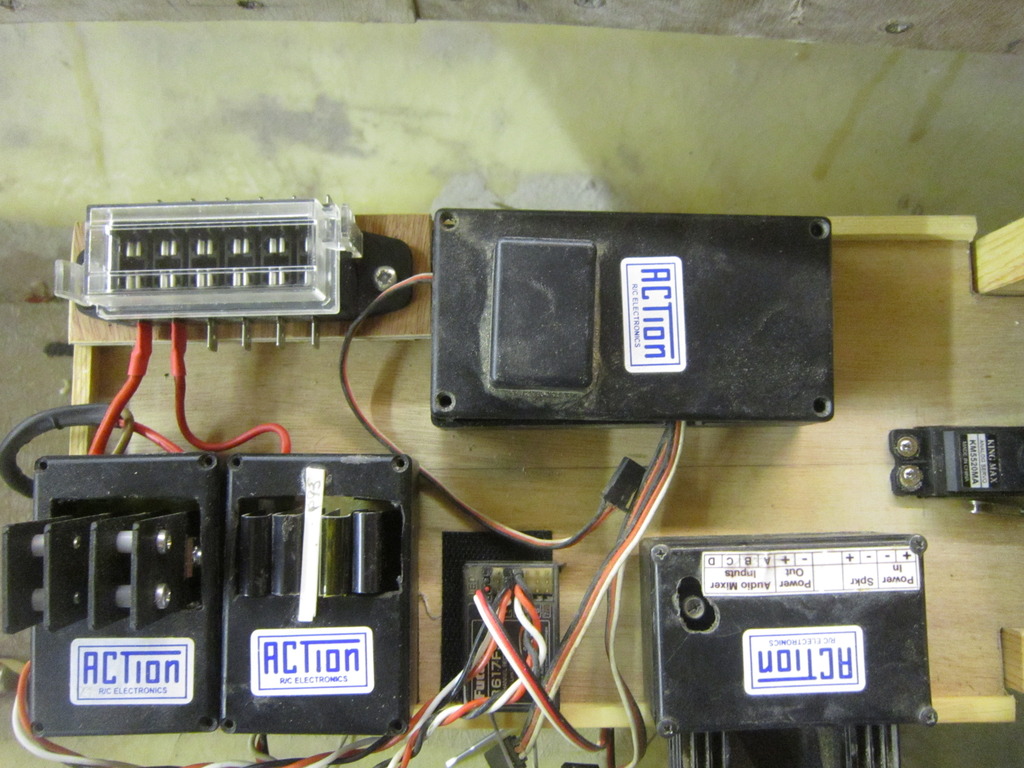

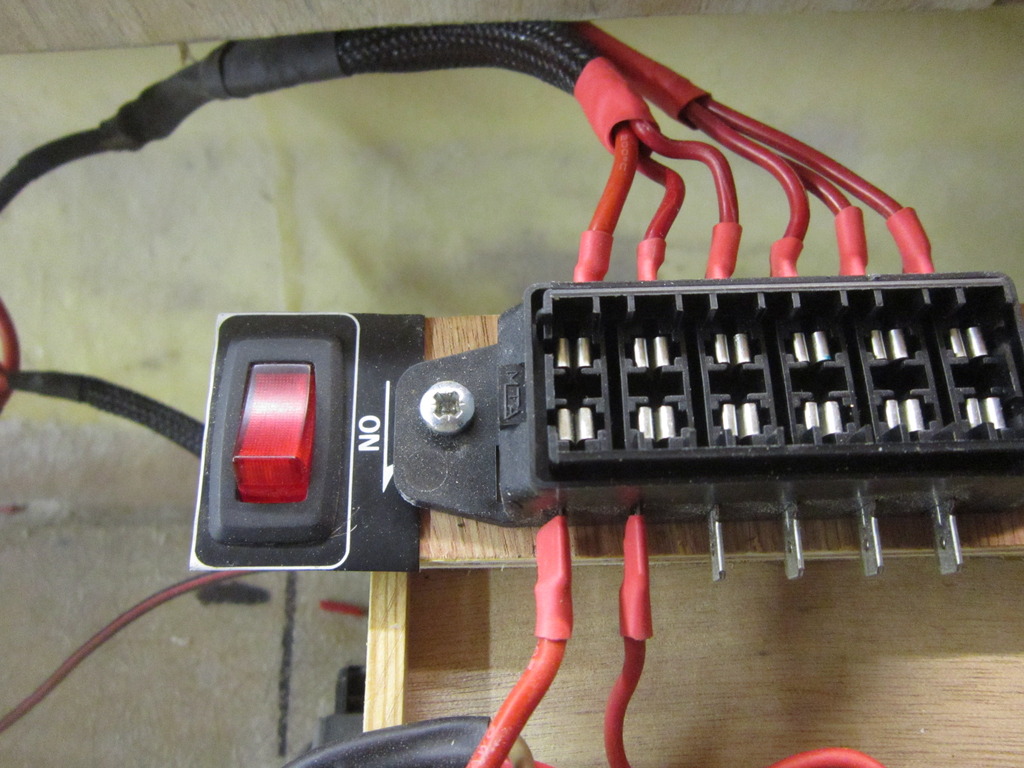

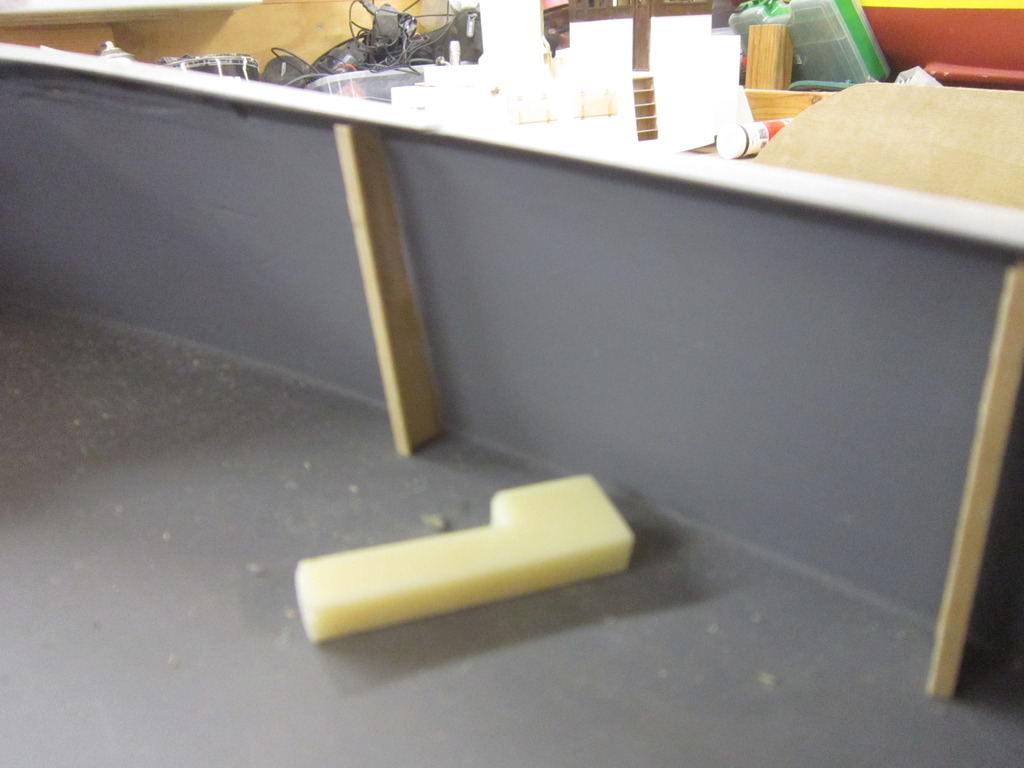

| So I started with the electrical instalation so a new servo piece of plywood was made and extended to cover the motor so I could mount all of the gear out of harms way The first to be placed on the mounitng board was the Esc....all the electronics being used are ACTion  I decided not to use the ACTion distribution board and use a car blade type fuse box to feed everything but to use an ACTion bec obviousy to feed the esc and reciever......The components placed on the board are a P98 High power esc,an ACion 93 Multy controller a ACTion Amplifier and a P100 Noisy thing  An illuminated rocker switch was also installed ...this will control a 40 amp car relay which when switched on will allow power to be fed to the fuse box etc  Pic of where the relay....all the power cables have been encased in some proper electrical sheathing and had the ends heat shrunk...............all the auxillary wireing will be encased in this as well,should keep Mr Milbourn Happy  Having run out of cable I decided to do i job Ive been putting off for months ....the bullwarks...unfortunately every single one is different so I cant mass produce then ARGHHHHH...so I needed to assertain the correct angle of the deck to the side....nothing I have would do this so I had to make on...a very simple tool....2 pieces of brass bar with a nut and bolt through it ............nothing beats simplicity in my mind.  Proof of the pudding 2 bullwark supports made....simply using some lite ply and some thin planks glued on edge to the support  Between some of the support these vents will be simply glued to the sides of the hull  Dave |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Wed Mar 01, 2017 4:54 am Wed Mar 01, 2017 4:54 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Wed Mar 01, 2017 9:37 pm Wed Mar 01, 2017 9:37 pm | |

| Let the fun begin oh what a right chore the Bullwark supports have turned out to be,each one has to be individualy made,oh the joys of boat building,mind you if it was so simple it wouldnt be fun would it. I have managed to get down half of one side of the hull in an afternoon so I hope by tomorrow to get the other side done,one of the most sattisfing well it was to me was being able to mount by vents to the side of the boat nad aslo the coaling scuttles....mind you they do say little things please little minds HA HA. A section of the sides with the supports and Gnv vents attatched to the hull sides  Coaling scuttles fitted  I also fitted some of the posts as well  Primer was applied to make them look the part  Dave  |

|

| |

dimtim

Able Seaman

Posts : 25

Join date : 2017-02-21

Location : derby

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  Wed Mar 01, 2017 10:57 pm Wed Mar 01, 2017 10:57 pm | |

| WOW looks like a beast stavros | |

|

| |

Sponsored content

|  Subject: Re: Models by design Tid Tug build...the Big un Subject: Re: Models by design Tid Tug build...the Big un  | |

| |

|

| |

| | Models by design Tid Tug build...the Big un |  |

|