|

| | Unimat SL1000 1970 lathe restoration. |  |

| | | Author | Message |

|---|

Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Unimat SL1000 1970 lathe restoration. Subject: Unimat SL1000 1970 lathe restoration.  Wed Oct 02, 2019 5:47 pm Wed Oct 02, 2019 5:47 pm | |

| So guys I’m after a new lathe for my workshop..

Problem is there are so many cheap Chinese ones out there sporting crap plastic gears or under powered belt drives or just piss poor quality, I’m struggling to find one that will five years or carefree use...

So I’m looking for suggestions and links, so if any of you have a small mini lathe or know of good ones let me know!

RR

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

Last edited by Roadrunner on Thu Jan 23, 2020 5:33 pm; edited 1 time in total | |

|   | | Windy

Gunner

Posts : 132

Join date : 2011-12-11

Age : 58

Location : Always at work...

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Oct 03, 2019 4:55 pm Thu Oct 03, 2019 4:55 pm | |

| Hi Mate, how much do you want to spend??

I have had one of these for about 6 years now & I haven't managed to break it yet!!!

https://shop.chesterhobbystore.com/collections/lathes/products/conquest-super-lathe

Mark.. | |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Oct 03, 2019 5:06 pm Thu Oct 03, 2019 5:06 pm | |

| Between £500/700 not including tooling and tail stock extras, that looks like one I looked at but didn’t state of the change gears are plastic like so many cheap ones... ??

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Oct 03, 2019 7:00 pm Thu Oct 03, 2019 7:00 pm | |

| why do you want a mini lathe, Aron, as it isn't much smaller than my Myford ML10, and that is bigger than a Myford ML 7, and you don't get plastic gears in those.

I've had my myford for 25 years and it was second hand then...………..it doesn't have a milling attachment like the mini lathes but I've never needed one for modelling anyway. |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Oct 03, 2019 10:50 pm Thu Oct 03, 2019 10:50 pm | |

| NI’m going to start making a slide valve and isolating steam engine shortly so that’s the main reason for the lathe also I have quite a few projects that require fittings that I can’t buy easily but I know I can make them specifically for the boats.. sadly I do t have room for a Myford even 2nd hand so it has to be a minature one but capable of doing the job I need, as for a milling machine attachment that’s a bit far for now most of the things I need are just turned but option for a mill would be handily later on

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Oct 03, 2019 11:19 pm Thu Oct 03, 2019 11:19 pm | |

| thought it might be space matey...………. the good thing about the modern mini lathes ism that you can usually add a mill attachment later...…….can't do that with a myford as they are separate units that stand alone. |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Oct 03, 2019 11:47 pm Thu Oct 03, 2019 11:47 pm | |

| Saw a fully restored myford on eBay today £3k lol looks stunning Just a shame I’ve not got the space or I might have sold one of the kids for it  https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.co.uk%2Fulk%2Fitm%2F223686209040

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 04, 2019 5:44 am Fri Oct 04, 2019 5:44 am | |

| Aron mine is a Taig, Peatol in the UK. https://www.youtube.com/watch?v=K_gN13LaoPU |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 04, 2019 9:29 am Fri Oct 04, 2019 9:29 am | |

| I’ll have a search for that one in a moment Damien,

Here’s what I’ve been looking at....

Two options, one being plastic gears but the machine looks very well made...

https://www.axminster.co.uk/axminster-model-engineer-series-c1-micro-lathe-505101

The other has lesser features but is belt driven with only a tensioner to change speeds...

https://www.axminster.co.uk/proxxon-fd150e-lathe-splash-guard-6-pce-cutting-set-package-deal-717739

To be fair I’ve been leaning to the first one linked, even with the plastic gears as I can prob get metal gears as an upgrade but that said I need to spend another £30 on the threading gear set too along with a Chuck head stock, etc etc....

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 04, 2019 10:53 am Fri Oct 04, 2019 10:53 am | |

| The Taig/Peatol comes as a kit.

http://taig.com.au/webstore/index.php?main_page=product_info&cPath=7&products_id=7&zenid=815a04afa7c20ad62402b330152fd5a1

the $499 AUD converts to 273.30 quid a sewing machine motor works ok for smaller jobs I converted mine with a 24v motor from a mobility scooter. |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 04, 2019 10:57 am Fri Oct 04, 2019 10:57 am | |

| Link for Peatol UK.

http://www.jeffree.co.uk/Peatol/lathe.html |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 04, 2019 1:30 pm Fri Oct 04, 2019 1:30 pm | |

| I looked at that, not my cup of tea to be honest it’s lacking some key components and functions it’s also smaller than I was looking for, also other issues is to mount it and a motor ( I really don’t want another diy project I want out of the box and works), tool lock is also on the back.... I’m not leaning over a lathe again....

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sat Oct 05, 2019 10:30 am Sat Oct 05, 2019 10:30 am | |

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sat Oct 05, 2019 3:49 pm Sat Oct 05, 2019 3:49 pm | |

| I bought one of the early peatol lathes for our school for kids to get used to before progressing on to the boxfords we had...……...the peatol was just so basic it was crap...……..easier to put the kids on to the big boys toys to begin with. |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sun Oct 06, 2019 5:02 pm Sun Oct 06, 2019 5:02 pm | |

| I’m currently bidding on an old unimat SL trying to decide its value now as its hitting new lathe territory lol guess we’ll see who snipers me at the end £350 or £400..... dum dum dum...

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sun Oct 06, 2019 8:05 pm Sun Oct 06, 2019 8:05 pm | |

|

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Tue Oct 08, 2019 8:54 am Tue Oct 08, 2019 8:54 am | |

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Tue Oct 08, 2019 2:56 pm Tue Oct 08, 2019 2:56 pm | |

| LOOKS a nice solid bit o' kit there Aron...……….hope you are pleased with it when you get it all set up. |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Tue Oct 08, 2019 8:56 pm Tue Oct 08, 2019 8:56 pm | |

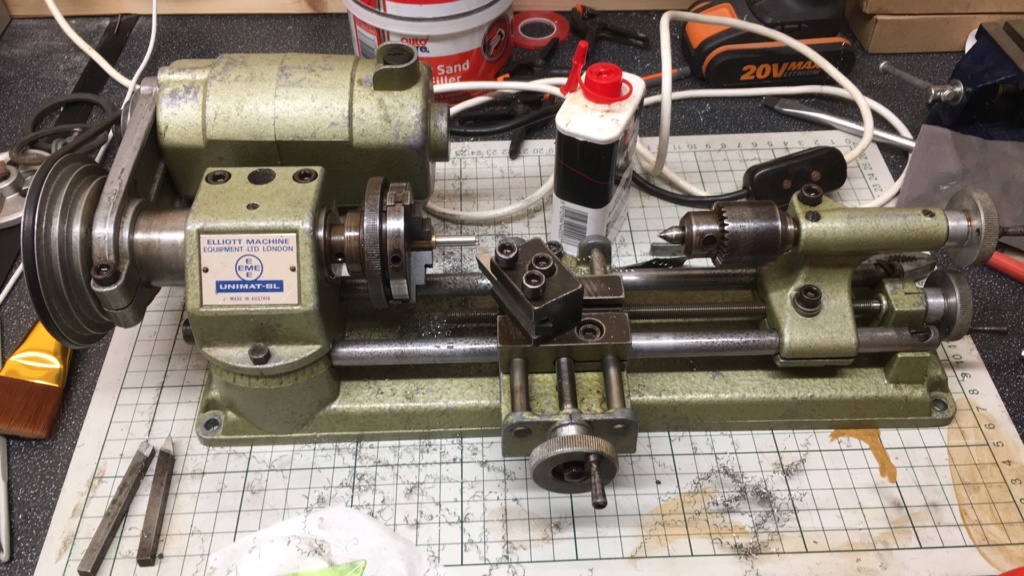

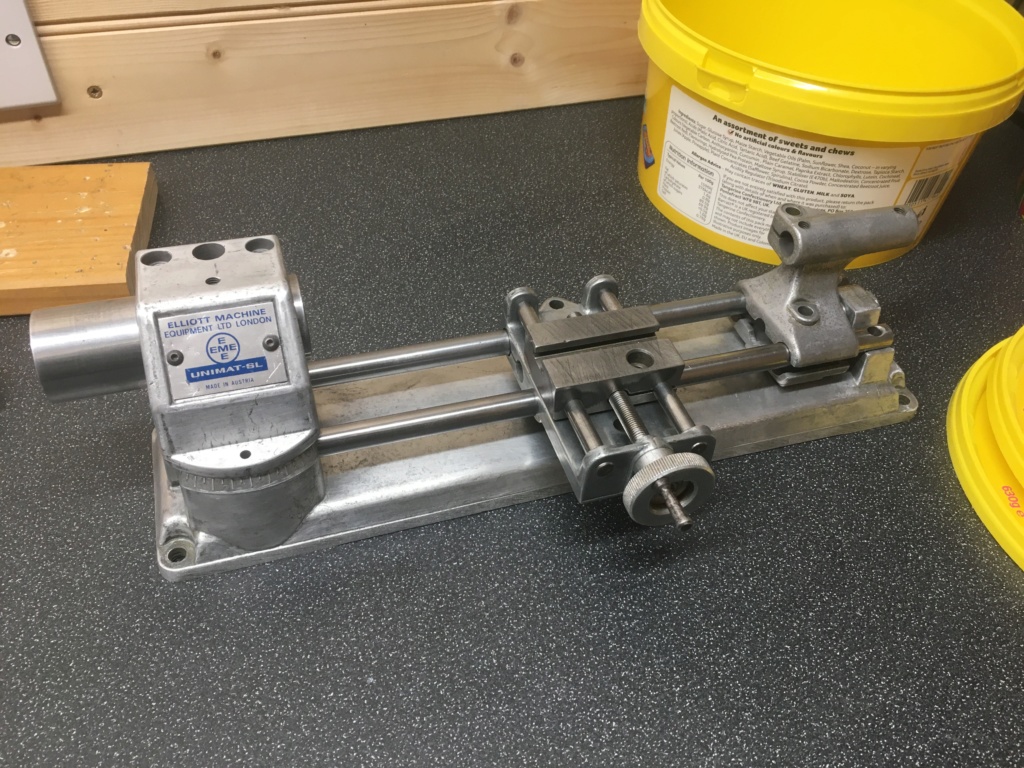

| Lathe arrived today next day delivery, all works flawlessly no give in the bearings, apart from some surface rust/blemishing a bit of pitting in the rails where the slide doesn’t run but and flaky paint works fine, tested on brass bronze and steel. I’ll run it for a while as is, and come next year I’ll strip it down and repaint it, and give it a good restoration... It dose need some new belts but that was expected... I was pleased to see even in this state the motor has barely been used.... a very good sign sing the brushes are still over just over half inch long! All in all a good machine, guess the old sayings true, old machines still run better than the latest gadget!

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Wed Oct 09, 2019 9:10 am Wed Oct 09, 2019 9:10 am | |

| these are the best mini lathes going. I bought mine 10 years ago and the motor is still going strong. keep it well oiled and and it will live you out lol.  david  | |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 11, 2019 10:29 am Fri Oct 11, 2019 10:29 am | |

| It’s running fine... the run off is also minimal. I do have to pick up a new set of tools for cutting the ones came with do not center up anymore simply because they have been sharpen to much ( probably with a grinder not a sharpening stone) I also cleaned up the head stock and removed the rust it’s now new and shiny! Along with a light buffing on the rails, basically I stripped it cleaned the funk off and put it back together... works great...

The only flaw I’ve found is the original on off switch... it’s tripped The power twice in the house when I go to turn it on, so I’ll have to replace that, but better the machine needs mounting on a base board long term I’ll factor this in...

Probably and nvr switch or a standard fused switch would work... I’m not a fan of the Chinese safely switches, guess we’ll see...

I’m also looking for the auto feed system as and extra for the tool ( helps with threading) so if anyone has that upgrade laying about send it my way! Only one I found on eBay so far costs £300 and it’s just not with it for a threaded bar and two mounting points!

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 11, 2019 10:31 am Fri Oct 11, 2019 10:31 am | |

| David is yours the dB? I’m interested in your head stock chuck... ( I also need to find a 4 jaw)... but because the unimat sl is a screwed on plate and not threaded to the spindle it’s hard to find an off the shelf one...

Where did u get it?

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 11, 2019 4:41 pm Fri Oct 11, 2019 4:41 pm | |

| the stock chuck came with it but i had to get new chuck for drill bits. this I got from USA I will try and find the web site when I next go into my garage, having health problems at the moment sorry. but they did sell a lot of spares.

david | |

|   | | davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 11, 2019 5:45 pm Fri Oct 11, 2019 5:45 pm | |

| hi arron,

just been looking in my files and found the place I used for drill chuck. its called,

blueridgemachinery& tools. USA, the drill chuck cost me $60 dollers US. they sell used and new parts they gave me excellent service.

also

sherline,com have not used them but recommended by some one. they have chucks to suit the 12mm x 1 thread.

i have got the 12mm x 1mm tap in the 3 sizes start to finish, if you are thinking of making a face plate etc.

while going through my files I found i bought mine in 2007 (shut your eyes) for £99.00 so if that is the going price you paid then i have made a nice profit.

also forgot i have the operating instructions for the unimat 3rd edition if you want a scan of it let me no.

david | |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Oct 11, 2019 9:47 pm Fri Oct 11, 2019 9:47 pm | |

| Thanks for the info something to look into, I need a few extras so that will come in handy, the lathe came with a face plate so I’m golden there, it also came with ty e original manual in very good condition, so a scan is not needed, I think the 3rd edition differs ina. Few areas to the SL 1000... Anyway thanks for the info

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Wed Oct 30, 2019 8:52 pm Wed Oct 30, 2019 8:52 pm | |

| Made a significant upgrade to the lathe today. For some odd reason the lathe would randomly trip the mains in the house just as I was flicking it on.... needless to say that the switch was at fault since it trips occurred the moment I touched the switch.... After some hunting about I purchased a 2 phase NVR on off switch from Axminster tools, this is a major upgrade in comparison to the old and very scare on off switch that came with the machine... Anyway fitted this evening and works beautifully. I opted to not buy one with a “e stop” it’s simply pointless as the machine would still need to spin down regardless of I hammered the off button or a e button, and to be honest all the machine in the shop accept the table saw don’t have an e stop anyway so it was kind of a redundant feature to add... also since this is a belt driven machine if your brave enough just grab the jaws it will stop fast enough  just kidding DONT DO THAT KIDS! Anyway old scary switch.....  New might save my life NVR switch.

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Oct 31, 2019 1:54 am Thu Oct 31, 2019 1:54 am | |

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Jan 03, 2020 3:50 pm Fri Jan 03, 2020 3:50 pm | |

| I’ve updated the lathe with some new parts that were originally missing, mainly a new live center! It’s quite hard to find anything with a 12x1 thread but I got lucky on eBay with the brand new live center.. I’ve also updated and brought new belts and lastly spend £30 on some brand new hss 1/4 cutting tools... the ones that came with were ok but require a serious amount of restoration and reshaping and sharpening to put right, and given I was missing the cut off tool figured a new set was the way to go. I’ll update this post as I progress on upgrades and it’s restoration as I get there, on a side note dose anyone have a m12x1 Tap and dia in there tool boxes? Happy to buy them if you do, be surprised how hard it is to find those anywhere and it will let me make up parts to convert a m14 threaded collet to fit the 12/1 thread! ( then I don’t have to cough up £200 of the original set!

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sat Jan 04, 2020 1:48 am Sat Jan 04, 2020 1:48 am | |

| |

|   | | Fredd

Deck Hand

Posts : 2

Join date : 2020-01-08

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Wed Jan 08, 2020 7:28 pm Wed Jan 08, 2020 7:28 pm | |

| Toolpost for three jaw chuck.

https://www.toolpost.co.uk/woodturning/workholding-chucks-faceplates-etc/micro-chucks

They do a four jaw scroll chuck but I find one with individual jaws more useful?

Hobby's and Hobbies

https://hobby.uk.com/four-jaw-chuck.html

https://www.alwayshobbies.com/tools/power-tools/unimat-4-jaw-chuck-162050

Do a four jaw chuck - Unimat 1 so not sure if it is plastic or metal?

Chronus

https://www.chronos.ltd.uk/product-category/taps-dies-boxed-sets-threading-accessories/taps-dies/carbon-taps-dies/metric-fine-carbon-taps-dies/

M12x1 Carbon steel taps and die

They do hss taps but cost a lot more and I find Carbon steel adequate for occasional use?

Fred | |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Wed Jan 08, 2020 7:50 pm Wed Jan 08, 2020 7:50 pm | |

| Thanks for the links very handy! I was after a 4 jaw chuck, but was going to convert a modern M14 version to fit but great job for those saves me hours of searching!

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Wed Jan 15, 2020 3:06 pm Wed Jan 15, 2020 3:06 pm | |

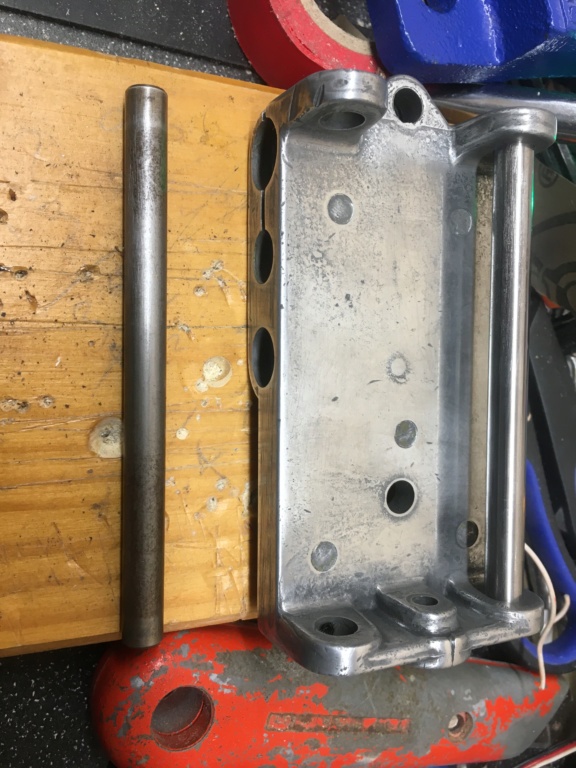

| Dose anyone here have the ability to make me a 62mm back plate for my lathe? I can’t do it myself as my max cutting depth is 60mm and that’s pushing it... I need a new back plate to fit a ER16/25 collet chuck to, my only options without a new back plate built to buy a 14x1 to 12x1 adapter then fit a 14x1 threaded back plate, which in total chews up a full 2” of cutting space on the lathe as well as being very untidy and a lot resting on that adapters thread! So if anyone is able to make me a new back plate here’s what I need... 62mm dia with a central 12x1 internal thread for the headstock spindle.. See photo for depth of cut, I don’t need holes for the collet drilled and tapped as I can do those on the drill press, I’m also not sure what size I need them at also... But if anyone with some time and a larger lathe can make me up 1 or 2 backplates with theb12x1 thread I’m looking for I’ll be happy to pay for your time and effort... get in touch please!!!

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Tue Jan 21, 2020 2:11 pm Tue Jan 21, 2020 2:11 pm | |

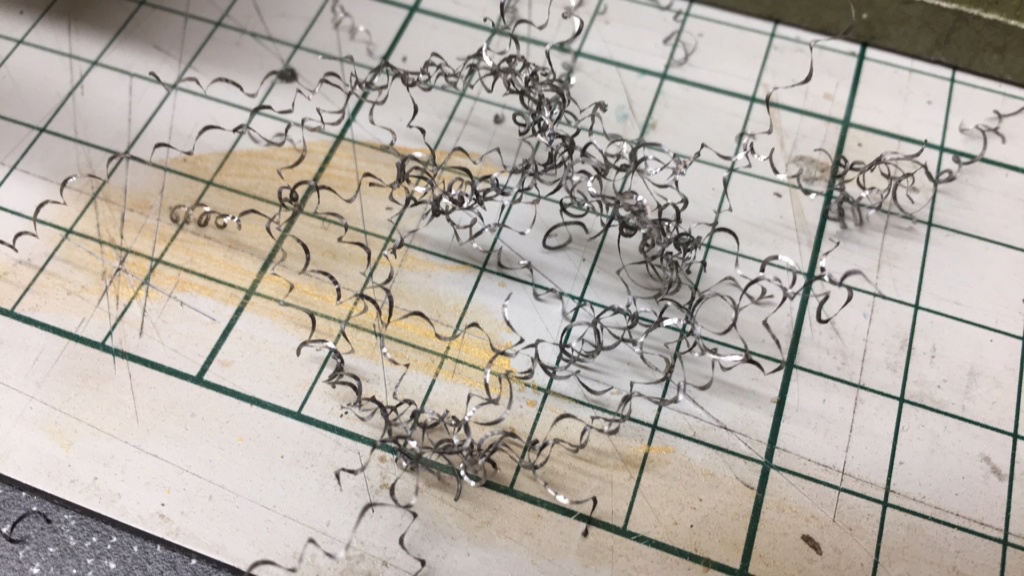

| I’ve been getting some odd chatter on the lathe recently and after eliminating a tooling issue since I have a brand new razor sharp set, And checking the backlash on the slide ( which is very minimal for a lathe this age, it can only mean one of a couple of things... user error ... unlikely now I’ve resolved the speed issues with a motor clean and new belts, or the bearings in the spindle. Now at first glance and spinning it by hand the spindle Moves freely and no play with a good firm lateral shake, but the bearings do sound worn, originally when I first received the lathe I gave the whole thing a good shot of wd40 to loose up the moving parts then went on to oil them, the bearings however have housings within the spindle head which I couldn’t get into and at the time I also couldn’t remove the chuck nor the pilot wheel that drive it, so I just dosed it in oil and hoped some would seep in, that seamed to work for a while and the sound reduced from the spindle but the sound has gradually increased and I’m also hearing some odd like crunching sounds when the motor winds down, leading me to believe I have a bearing issue... So today I’ve stripped out the spindle head to remove the bearings, and the bearings look “ok” as In Terms not bad for 40 years old, but there was a lot of grime surrounding the bearings and balls this indeed looks the case of some worn bearings, how badly it’s hard to say but it’s clear the bearings have run dry for long periods and the dirt is black and thick and almost solid in places. So fortunately I’ve managed to locates some replacement original bearings brand new for this lathe and they also come with new thrust washers, although the ones I have fitted look fine and still retain their shape for absorbing thrust, so while those are on their way I’ve started to clean up the spindle head, remove the rusty spots and just generally make it tidy, I won’t go as far to remove every mark on the head as the motor and pully brace clamp back on over some of the more marked areas but I’ve got it to a reasonable looking polish making it no longer look 40 years old, all I have now is to wait for the new bearings to arrive before I reassemble. I think this marks the start of my lathe refurbishment.... it’s now pointless to just fix bits as I go when I may as well restore the thing now and be done, the motor itself I will have to source a refurbishment establishment to take care of the motor As when I did open it to clean the carbon it’s still very black in places and I’m not electrical engineer so out sourcing it to be rewound, cleaned and have a new cable installed that’s more than 8” will have to be done... But for now here’s the efforts of my clean on the spindle...

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Wed Jan 22, 2020 3:13 pm Wed Jan 22, 2020 3:13 pm | |

| Today I’ve started the strip the paint from the lathe, I’ve removed all the components to its base parts, all aluminium castings and stripped the paint from the head stock, slide and tail stock, the base was also give a strip but the process didn’t work as well so I’ll have to manually sand the paint of in the worse places, give the lathes age and it’s cast aluminium I opted for a older method of paint removal which was to boil the parts in bi carb, I don’t think a chemical stripper would have got the paint off without some damage to the castings, having not used a stripper before other than heat removal this was the lesser of evils, and given the head stock has a bored shaft hole and surfaced mount I wanted to avoid damage to these areas, for the most part the paint come up fine Iva had some oxidisation which I removed as much as I could with white vinegar, the remaining low dark spots are the casting itself, I’ll do my best to bring most to a good shiny finish, them primer with etch befit top coat, sadly with the castings far from perfect polishing them would be a waste so keeping somewhat faithful it will be a paint finish. The motor I will have to chemically strip as I can submerge it also the motor casing is steel so I don’t want to introduce rust to the motor, I will do the motor last after the lathe is together again, I may just chest and give it a good sand prim and paint with out stripping it, not for lack of effort but more for I still want the motor refurbished later and not everyone can ensure a perfect paint job returned for doing that job, either way it will take me a few days to get these parts sanded and shiny ready for painting.

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Jan 23, 2020 3:45 pm Thu Jan 23, 2020 3:45 pm | |

| Well after a good morning of wire brushing, 180,400,600,1000,1500,2000 sanding the base it now all done and the machine just needs a final check and prep for undercoating, I’ve even removed the name plate and drilled and tapped holes for the original plate to screw on and off, the motor however I will just give that a scrub with the wire brush, and a quick sand with some 180 grit to remove any loose paint, and flatten what’s there and prim that with etch and filler primer before top coating. Now all that remains is to clean up the other parts, screws, drill chuck, 3jaw and the screws and threaded rods and handles. The handles them self’s I will need to get some aluminium clean and polish as I don’t have any and I don’t think brasso will do the job? Anyway needless to say it’s starting to look like a new machine and honestly isn’t that many parts to strip and clean, I guess since it’s a mini lathe it’s expected to be simple.. any suggestions on a paint colour?

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sat Jan 25, 2020 1:56 am Sat Jan 25, 2020 1:56 am | |

| Had a good day today, my new bearings for the spindle arrived so those were fitted and packed with high temp lithium grease, looking at the new bearings to the old you can defiantly see the difference in the balls and the wear on the old as the originals have a what looks like a sanded finish over the mirror version of the new, needless to say the new bearings all greased up run much better and feels smoother. Let’s hope that is the fix I need... As you can see from the photo I’ve also had a delivery of all new spares of stainless steel bolts and grub screws, washers, rail bolts and lock nuts and many other odds and ends to bring the lath up to date and rust free!  Now once I fitted the spindle together I had to test it and run it in a little so I could torque up the spring washers to the right force and ensure the belt his didn’t come flying off.... and this led me to my actual 6 hour job... the motor has been running ok since I got it but there were a few things bugging me, one of which was the motor power lead being to short and the rotor was able to shift in and out of its bearings by 2-3mm, I know a lot of motors do have some play in the rotor but this time when I fired it up I was hearing an intermittent knocking sound.... the motor was running ok still but something kno Ming about ment something was loose, anyway to cut a long story short I figured I would google how to strip a motor down, I got lucky I found a site dedicated to unimats and was able to find the full stripping instructions to this motor... so saving £100 I took it upon myself to strip this motor down and clean it myself... and this is where I found the issue, the capacitor went soldered to the brush housing, I’m not sure if that was my fault or just wear and tear but from what I had to do to repair it it was clear the soldered end had snapped off...  From there I was able to see what else was going on... the rear bearing wasn’t seated in its frame so it was floating up the rotor shaft but stopping as it hit the brushes, I think i got lucky the brushes weren’t damaged, so after pushing it back into its housing I couldn’t shift it again, clearly this is a tight fitting and maybe has never been seated since day one, as the back of the housing under the bearing was chock full of carbon dust, and lastly, I managed to locate the section of the cables which allowed me to unsolder the old cable and install a new one, nothing complicated just very dirty! Hence the lack of photos on this job, anyway finally got everything clean and back together and tested, motor works better than ever, the rotor no longer rocks about, there is deffinatly more power in the motor now and it’s much quieter, all in all a good day! Tomorrow I’ll strip the paint of the motor housing now I can get it apart and back together with no fear of breaking it.

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sat Jan 25, 2020 9:00 am Sat Jan 25, 2020 9:00 am | |

| hi , I have been watching you do all this work and very interesting it is. I might have a go with mine now, I begin to feel more like it. not touched any models for 12 months due to health problems.

keep on showing please.

david | |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sat Jan 25, 2020 3:49 pm Sat Jan 25, 2020 3:49 pm | |

| Honestly it hasn’t been that much of a pain to disassemble and clean, I know full hog stripping it is a choice to clean up paint work, but to be fair since it’s aluminium the original paint work was bad and I’ve seen other unimats in worse shape, this is due to poor paint from the factory and the primer they used (if any) has allowed thy be paint to chip up so easily, I expect it’s one of the early hammerite paints from that era, don’t get me wrong my lathe although worn wasn’t in bad shape for it’s age, but I had a few issues to fix that I knew went right.

Talking of paint the paint was so easy to strip that bicarb of soda just ripped the paint clean up in boiler water in 20mins, it worked out cheaper and easier than paint stripper and no nasty fumes of chemicals, the lathe bed wasn’t that hard either even after the paint looked like it wasn’t moving but some 180 grit ripped what was left very quickly, my only issues been oxidisation and keeping it back, so thing I’ll do more of before I prim it.

The bearings knowing from day 1 they went tapered rollers I figured they only needed oiling lime oil lite bearings, sadly with the chatter I’ve been getting with new cutting tools it was clear something was wrong. Now he new bearings cost me £20 and e stainless screw set was another £20, looking back to my original purchase price And the parts I have brought for it I’m still only breaking the same as a brand new modern minature less it’s parts I would need! So all in all this was still a great purchase.

My main concern is dialing everything in so I have some plans to help with that by adding custom dial indicator mechanics to the machine, which will help a lot my only problem will be with the tail stock, as that has no adjustment and your as per the manual suppost to just tweet the stock head to align the tail stock, this is fine for use with and arbor I guess but i know for a fact your end up cutting in postive tapers to the work long term, this I intend to make a work around for and dial in the head stock and shim the tail stock to perfect, I will get to that as and when I’ve got the head stock perfect, as I have a coupe of different methods to fix this which one depends how bad or how permanent I need the fix.

Truth be told besides the switch and belts I could have just opted to swap out the bearings and left it alone and I’m sure it would have been fine ( assuming I did the motor repair too) but honestly these machines are going for silly money on eBay and a good restored version well I have options once it’s done to resell and but something else, or just use it as intended, I’ll be honest keeping it is my plan if I wanted a better of different machine I would have brought one to start with, at the time I had my eye on a ML7 for £1800 factory new, just happened to be a show floor model in some personal small business. But space it’s a premium in my shop, and Chinese crap is not my thing..

Long live the unimat I guess 🤪 let’s see how it fairs after the finished rebuild!

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sun Jan 26, 2020 6:43 pm Sun Jan 26, 2020 6:43 pm | |

| Today I took the majority of the paint of the motor casing, it still has some green areas to finish cleaning it up completely to which I’ll finish those later this evening, but for the most part the paint case off easily using only a razor blade to scrap it off, the paint really was that bad at this age it literally was able to flake off the casing with the minimal of effort, this could be the paint itself if he fact the motor heats up and years of this has effected he paints ability to stick, that said while scraping the paint it’s clear no primer coat has been used to paint these unimats so paint chipping would have been inevitable given aluminium’s inability to let paints adhere to it, so coming to the conclusion this is some for of enamel based paint, maybe even lead based, I’m hoping that my new out job will survive much longer using modern etching systems and lacquers. All in all not a bad couple of hours to clean up the motor casing exposing what it an aluminium case not a steel one as I originally though. I’m hoping my etching primers arrive tomorrow so I can get the parts cleaned up and primed, and able to sand out the low spots giving what should be a much better surface finish, although I’m not overly worried about surface imperfections, it’s not a show piece after all, but a decent finish will be worth the effort. I’m still undecided on colour for this machine, I’m not inclined to find a match for the original colour and keeping faithful, that said I do want to find a dull 70’s style colour that would suit the machine over a modern blue or red, white and cream colours are out of the question after all after a few years those will show up the dirt and oil stains, I’m currently leaning towards a grey, or possibly a sea green, I have many of those colours spare in the paint box, and grey wouldn’t be a bad contrast to the aluminium parts that are to be left bare, I think I will prim the parts and do a tester on the base of the slide with the colours I have and see what looks best, it’s an area never to be seen again after refitting. Guess we’ll see...

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Mon Jan 27, 2020 6:17 pm Mon Jan 27, 2020 6:17 pm | |

| Today even with the cold and thunder storms going on, thank good for a heated workshop, I made up a spray booth from my table saws giant box, and gave the lathe parts a good wipe down and a couple of light coats of etching primer, I’ve yet to do the motor I will do that shortly before bed so I can move the current parts indoors to harden overnight on the heaters and the workshop to air a little. So far fingers crossed the paints sticking fine and I’ve not seen any areas of concern from contamination, oils or finger prints... tomorrow will be the tell tail sign if the primer took when I give it a light rub down to flatten it if anything chips up, but from the current prodding I’ve done today I think the etch has taken very well so I’m hopeful I won’t get any issues, that said I always plan ahead and brought two cans of etching primer for this job just for a couple of mishaps. I’ve masked up the critical areas where movement or smooth operation is essential, the headstock rest, and inner bored areas with tape and rolled up paper, I will have to clean up the edges of these sections obviously, minor issue with a paint job like this, I don’t foresee any issues long term.

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Mon Jan 27, 2020 9:46 pm Mon Jan 27, 2020 9:46 pm | |

| Finally got round to doing the motor this evening, simple task to mask up the spindle, cable and the badge on the casing which I didn’t fancy trying to remove like the lathes label which was a pain. I’ll let all this harden off over night and tomorrow I’ll rub it all down with some 600-800 grit, and see if the primer coats held, if it’s all successful then it will be into colour coat... if I can pick a colour! If the primers not stuck in places or peels up I still have half the first can left, it’s surprising how far these cans of primer have gone usually I would be on the 2nd can doing a normal model and these have more surface area! I guess a decent can of etch primer goes a long way now, to be fair they are 500ml cans over the 250’s I usually get...

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Tue Jan 28, 2020 11:24 pm Tue Jan 28, 2020 11:24 pm | |

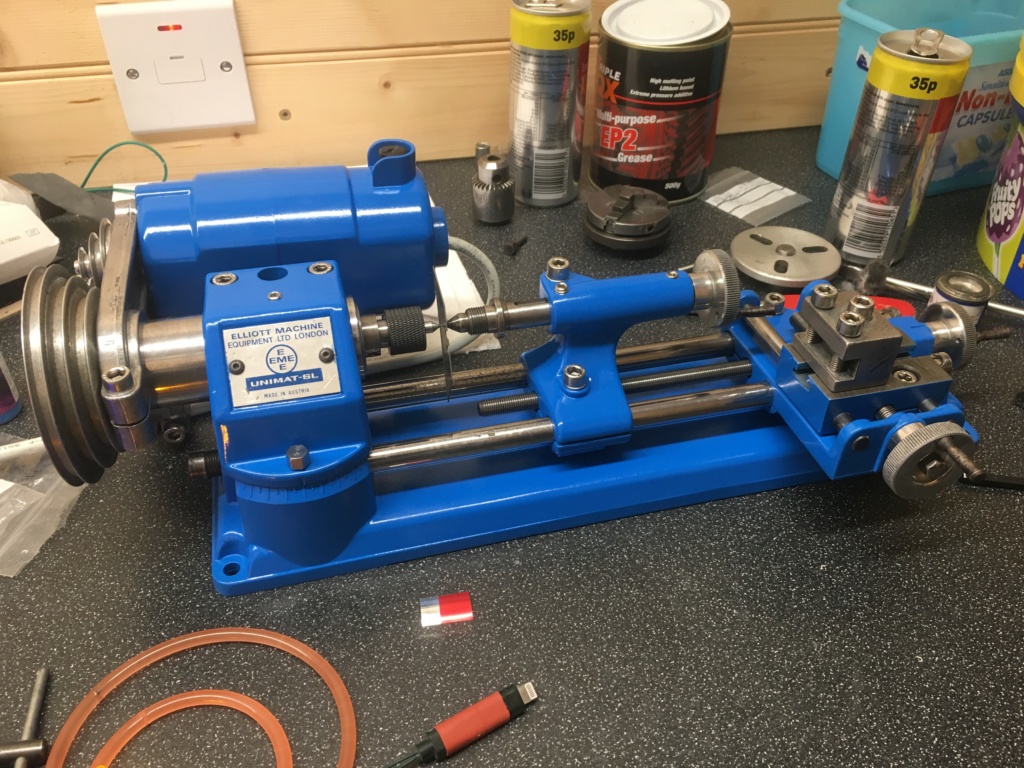

| Today I started applying top coat colour, something a little modern and a colour I have a ton off that I just can’t get rid off  it’s a bit bright just being freshly painted but it will dull down a little once it’s lacquered, deep electric blue! Of course right now that looks a little overpowering but with the stainless hardware and once all the other parts have been buffed and polished up it should be a nice modern contrast! I’ve yet to do the motor, I will do that tomorrow now as I have to give it 24 hours between coats to really harden up as the motor is too heavy to flip after an hour of normal “touch dry” it will just mark up the surface, I will see how this colour is tomorrow and decide if a 2nd coat is needed but I think at present the single coat is enough, it’s good coverage paint I’ve been using from Vallejo, more so it’s from the colour range my son uses on his war hammer minature, many of those are puter castings or plastic and they seam to hole up very well to abuse and his don’t have a top coat of lacquer protecting the paint! To be fair the lathe can be restripped and repainted over and over with no ill effects, so short term chips and such can be patched up, when (if) it ever gets to tatty it can be billed back to base and redone, nothing rocket science nor even hard work, in total for painting its only cost me £15 so thy etch primer, colour coat bottle and lacquer. With what I purchased to do the job I actually have enough left to do it 3 times over! Anyway enjoy the paint colour

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Wed Jan 29, 2020 4:13 pm Wed Jan 29, 2020 4:13 pm | |

| Today I’ve lacquered the main body parts with 3 coats it’s not worth going over that simply as this won’t receive a polish like a car but the paint finish is good enough to be high gloss and shiny new, it’s also pointless polishing this as the metal has many imperfections, moulding lines and machining lines cut/cast into it so achieving that mirror finish would result in many areas exposing the bare metal through sanding and buffing even carefully, I have one tiny spot of white on the base of the tail stock which I think is a particularly from where I’ve been smoking in the workshop (damn fag ash) I’ll have to see if I can get that off when the coats dried, ( I’m hoping it’s just surface stuck) but if not a light sand on that area and a quick spritz should fix that. The lathe bed has the “worst” look as it’s not fully gloss all over this is more to do with the metal itself rather than paint, it’s not bad but fortunately the area effected is the main bed which for the most part is not fully exposed to sight. Noting to be done without wet sanding it which simply is pointless since it’s a high damage area, I may look to make up a chipping tray to make clean up easier anyway so the finish in this area may not been seen anyway. Later this evening I’ll paint the motors base colour, I’m going to see if I can rig it upright so I can spray t h e whole thing floating in the air, the spindle itself has a hole for the pin of the belt drive, I maybe able to use that, I’ll see if I can jog something up if not it will be done in two half’s dragging out the time this is going to take. The main parts are now on the heaters indoors and will be left 2-3 days to fully harden before I can ream out the overspray in areas where rails and such fit, I did my best to mask these with paper rolls to reduce build up but the edges I left so I could feather them in so not to rip the paint work around the shafts making this become very untidy in moments.

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Jan 30, 2020 9:05 am Thu Jan 30, 2020 9:05 am | |

|

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Jan 30, 2020 3:37 pm Thu Jan 30, 2020 3:37 pm | |

| Glad to see you are using a quality primer there their Satrin Black and red primer are out of this world for coverage and longetivity

Dave |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Jan 30, 2020 5:56 pm Thu Jan 30, 2020 5:56 pm | |

| Took a chance today and checked the paint work, it seamed very hard that I wouldn’t leave finger prints from being handled, so I opted to clean all the bores out before the paint really goes rock solid, it also allows me to fit the machine handles on and grind the paint in the areas they usually would now again before the paint really hardens and starts to bind the handles later as the paint chips, since I was there I figured I would just carefully reassemble the machine, I still have to polish up the operation handles, pully wheels and it’s motor support frame but those don’t effect the whole machine or it’s paint work from handing, with the stainless steel nut and bolt set it’s really starting to feel like a new machine, looks the part too! I’ll update this a little later now once I can get the aluminium parts polished or at least clean. I opted not to replace the running rails for the slide, they are simple 12mm silvered steel rod, and easy pickup on eBay for £7 a 400mm length ( this only needs 330mm) however these rails still run perfectly true and the pit marks don’t effect the lathes running so instead of risking getting some bendy new ones on eBay I’ve left these alone for now, should they get really bad later it’s a easy fix instead I’ve given them a light buff and polish and leave them be, again h thy r machine isn’t factory new it’s one thing to replace everything it’s another to just waste money, that said I did waste cash on the stainless screw set, most of the screws although had some surface rust build up showing through their blackened state and again worn went not in bad condition, intact they are just stored now in the spares box covered with a bit of grease to ensure they don’t continue to rust away, there are a few updates to the lathe to make still, one will be a stop for the slide, I had been smacked into the chuck once or twice in it life going off the indents on the slide itself, (that wasn’t me) so I will make up an adjustable stopper to fit to the rails, I’m also going to make up a dial indicator for the x and y of the slide this allows me to center up the Machine Correctly but will long term give me better accuracy to the work I’m doing, I did locate a DRO for these lathes but that cost more than the lathe itself, spending that I may as well have got the Myford! However fitting semi decent dial Indicators will do just fine but I’ll have to save up some penny’s for the ones I want since there £100 each  I also need to build this machine a base board, that will be up next this week, I have some spare work surface from the workshop build, I had to cutoffs from fitting the counter tops so one I will cut down and mount the lathe to it it’s 22mm thick and work surface generally is good and flat along with the surface being hardwearing. I was originally looking to make up a box for this but I may do that a lot later depending on how I store the machine, but for now a de dent size base board if required. Anyway sneak peek at the machine currently... more to come, and see that paint colour isn’t that bad now! ( well at least it matches all the other machines now)

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Thu Jan 30, 2020 11:33 pm Thu Jan 30, 2020 11:33 pm | |

|

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Fri Jan 31, 2020 9:04 pm Fri Jan 31, 2020 9:04 pm | |

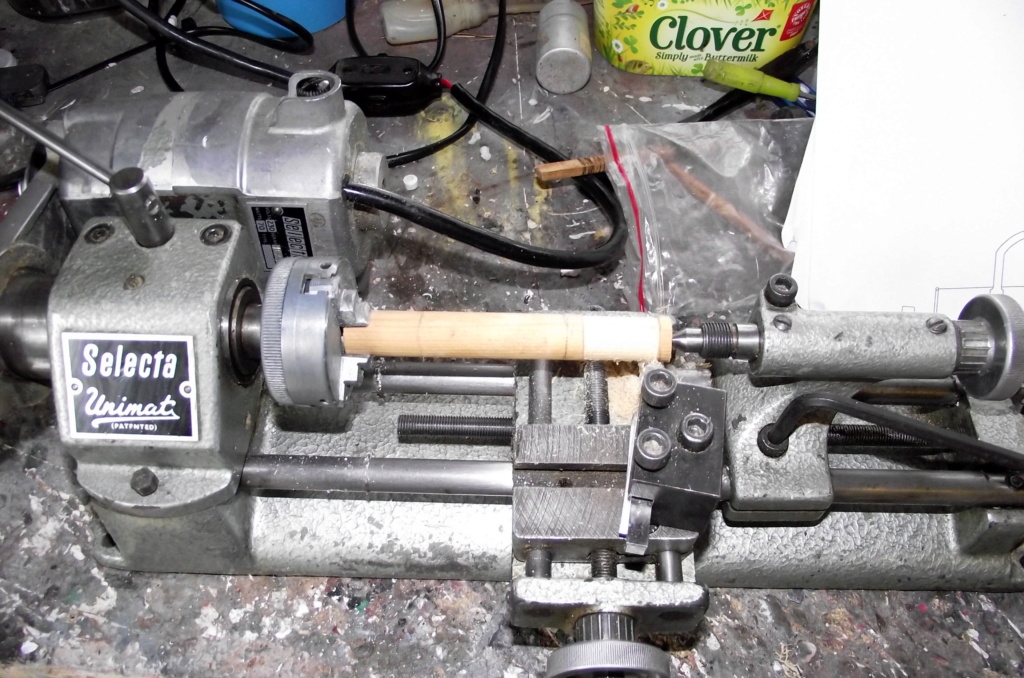

| Today I reassembled the lath completely, and have started to align the tail stock to the head stock, although not perfectly accurate by the use of a dial indicator, I opted until I buy a pair to old school it, little trick I picked up at work of and old boy who I swear never used a measurement I. His life to make anything yet things always fitted like a glove! I will endeavour to dial in the head and tail stock far more accurately once I make up the base board and purchase some dials but until then old school alignment anyone??

_________________

I'm Not Anti-Social, I'm Anti-Stupid.

| |

|   | | Roadrunner

Forum Overlord

Posts : 1715

Join date : 2011-06-10

| |   | | Guest

Guest

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  Sun Feb 09, 2020 10:34 pm Sun Feb 09, 2020 10:34 pm | |

| |

|   | | Sponsored content

|  Subject: Re: Unimat SL1000 1970 lathe restoration. Subject: Re: Unimat SL1000 1970 lathe restoration.  | |

| |

|   | | | | Unimat SL1000 1970 lathe restoration. |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| |