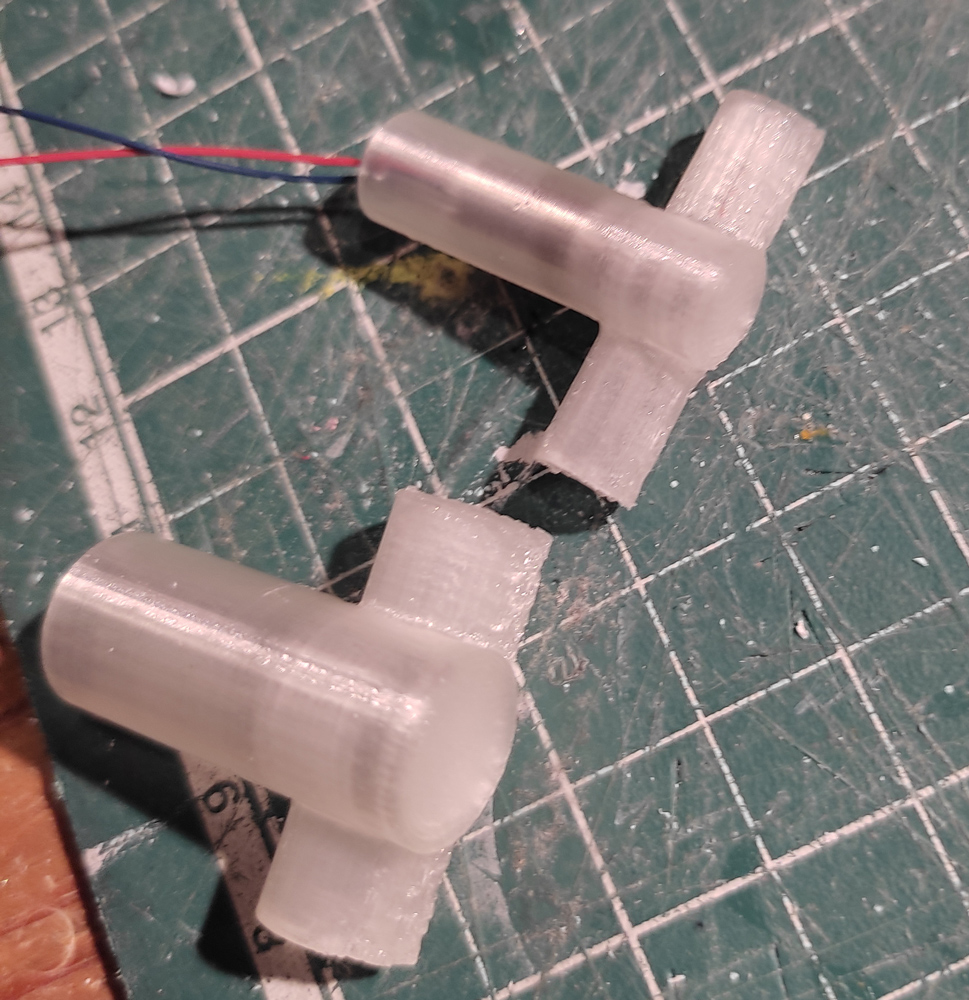

Yeah, the bow thruster.

Basically not so dramatic, takes a while until it works because of the limited size of the parts:

the advantage of 3D print: if it*s too large just print it smaller.

Very easy construct, just a rotating plate on a 4-6mm motor (from a toy helicopter)

Both tests with 1,5V

https://www.youtube.com/shorts/auzuqKb7IPU

https://www.youtube.com/watch?v=Y_gskFtAQXM

OK, that was it for a while. Mounting motors and light etc. you have only one chance and correctiona may create larger damage, also some modifications need to be done before further building the superstructure.

Therefore I decided to build an easy springer tug in 1/72 just for learning....

Well .... you know how it is when creativity takes over.....

A springer tug with one barge, built by hand and 2 printed version as well as a ponton .... crew for tug and Severn....

If there is interest I can write about the tug too.

For the Severn: There were mainly two options used for the steventube ('Stevenrohr') and shaft, either some shaft bearing (copper or brass tube on the tube ends) or simply soldering tin with a hole for the shaft.

The tug has a 1.2mm inside opening of the tube with soldered ends, grease inside. For the severn I ordered 1.5mm inside tubes plus end parts of copper. Againg there will be a grease filling tube soldered to both.

Propeller may be printed 3D. Motors will be 7mm 12000rpm micromotors running with 3,2V.

Coupling will be a ballpoint writer spring with mounting ends of brass (handmade by a friend).

I will finish the tug first (light and radar) hope to have the severn at least running in early april.

Have a nice and healthy 2023.

Best,

joerg