| | STEAM HYDRAULIC LIFEBOAT |  |

|

|

|

| Author | Message |

|---|

Guest

Guest

|  Subject: STEAM HYDRAULIC LIFEBOAT Subject: STEAM HYDRAULIC LIFEBOAT  Sun Jul 02, 2017 3:13 pm Sun Jul 02, 2017 3:13 pm | |

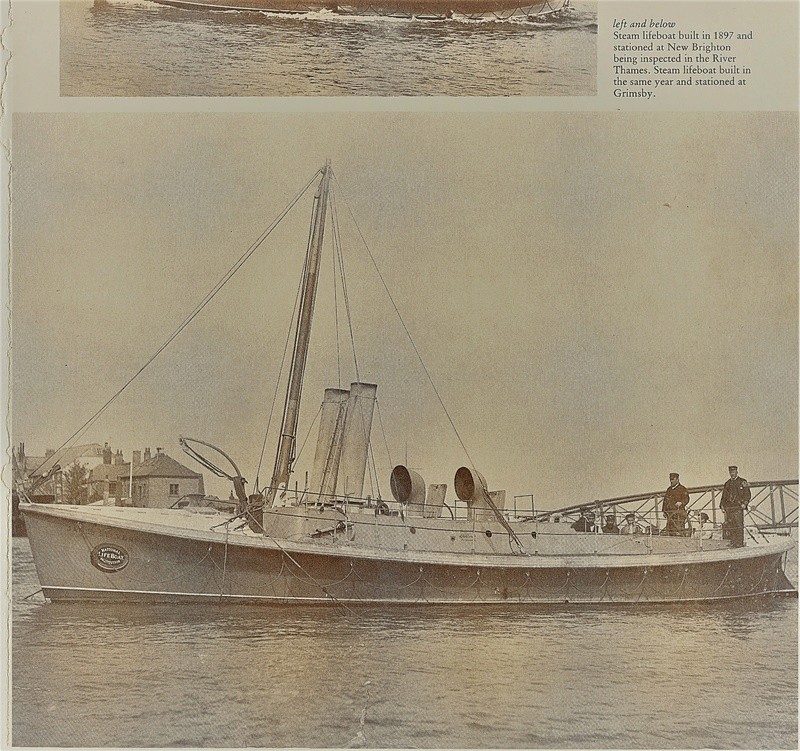

| Well, the long build has finished, the plans, spare fittings and masters have been put away. the parallel square on my drawing board repaired using some ply wood, screws and nuts and my trusty old Sidchrome 1/4 drive socket set (bought in Australia 42 years ago to mend the shoddy timing on my Norton 850 Interstate lol), after the accident a few weeks ago, and some tidying of the benches has been done. The workmate has been cleared and I will have had a clear up by Tuesday to get rid of the craaaaap on the other benches and floor, but I couldn't resist bringing in the plugs for the new project. This is to be a hydraulic driven "steam" lifeboat dating back to the late 19th Century......in essence she was one of the 3 steam driven Water jet propulsion lifeboats...........so nothing is really new. this model plug was recognised immediately as a steam lifeboat by both myself and Martin Kinghoward when it appeared on Ebay described as an "old wooden boat needing restoration". I spoke via email to martin, and came up with a deal that if he were to buy it and have it shipped to me, I would make moulds of the hull, end boxes and a superstructure, and send a set of mouldings to Martin.......deal done it has sat in my kids Wendy house for the last 3 years or so. Hopefully this will be a full build of a working lifeboat driven by a brushless motor driving a centrifugal water pump through fore and reverse nozzles.         |

|

| |

gribeauval

Master

Posts : 500

Join date : 2011-06-11

Age : 73

Location : West Yorkshire

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Jul 02, 2017 5:57 pm Sun Jul 02, 2017 5:57 pm | |

| Bit of work to do there before making the mould mate!!  | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Jul 02, 2017 7:55 pm Sun Jul 02, 2017 7:55 pm | |

| certainly is mike.......and quite a bit of the filler has bloomed around bow and stern so have been chipping off in small amounts ........thing it was from being stored in the Wendy house........although dry, it probably can be damp in wintertime..........but hey ho.........part of the enjoyment |

|

| |

gribeauval

Master

Posts : 500

Join date : 2011-06-11

Age : 73

Location : West Yorkshire

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Jul 02, 2017 8:32 pm Sun Jul 02, 2017 8:32 pm | |

| Half the fun is sorting out the problems!!  | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Jul 02, 2017 8:53 pm Sun Jul 02, 2017 8:53 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Jul 03, 2017 2:04 am Mon Jul 03, 2017 2:04 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Jul 03, 2017 8:57 pm Mon Jul 03, 2017 8:57 pm | |

| I left the plug in a heated garage to dry out last night and all day today, after chipping off the bloomed filler in large lumps. tonight I glued them back on with 2 part epoxy.......most of it went back on, with one piece left for tomorrow. once I have filled between the parts, I will give all the plugs many coats of sanding sealer in order to harden up the softer parts of the MDF which it is actually made of........ this is a case of getting the plugs ready for working on with sanders to get it to a better state before progressing on to getting it ready to take paint to highlight the parts needing surface fillers and then detailing before waxing ready for mould manufacturing. this part of the build is crucial for the best obtainable finish on the mouldings. I also need to find the one photo of these vessels that prove that they were plated steel hulls with overlapping. once I have found this single photo that I once had, so is available somewhere, I will plate the hull with 120 gram card.      |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Jul 04, 2017 2:29 pm Tue Jul 04, 2017 2:29 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Jul 07, 2017 7:04 pm Fri Jul 07, 2017 7:04 pm | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

| |

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Jul 08, 2017 2:37 pm Sat Jul 08, 2017 2:37 pm | |

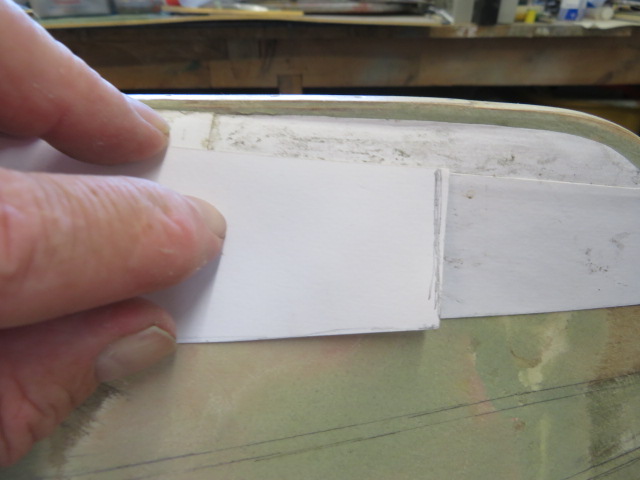

| probably right, Barrie. anyway, got some today from a small shop............not the stuff I usually use but an easy sander so that's ok. got a bit more done to the plug. the stem and stern post at 4mm was too thin scale wise, and so today I cut strips of 1.5mm birch faced ply 6.5mm wide, and in two layers I laminated them on to the original posts, using glue and picture framing pins. it was then just a simple task to infill with polyester filler [pf] once set I will then start filling the rest of the hull before sanding it all down.     |

|

| |

inertia

Midshipman

Posts : 99

Join date : 2015-02-08

Age : 72

Location : Nottingham

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Jul 10, 2017 12:51 pm Mon Jul 10, 2017 12:51 pm | |

| Neil

That green filler looks a bit like Flexible Plastic Padding body filler, which I have used in the past and is OK. These days I use P38 although I've been recommended other stuff by Stavros - who seems to know a little bit about car body repairs...

I have a vague suspicion that I might be co-opted into helping design a radio installation for this wondrous beast. Have you any ideas what sort of pump and valves you are going to use and how they are operated? I've done a successful bait boat propulsion system using four Rule 1100gph 12v bilge pumps and an ACTion P94 with a special array of Schottky diodes, but your proposal is new territory. Forewarned is forearmed, as they say!

DM | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Jul 10, 2017 2:16 pm Mon Jul 10, 2017 2:16 pm | |

| that's the stuff Dave.......I had that in stock but thought it too runny, but it has done well.......the problem was I thought I didn't have as much as I had, and thought I needed more than I do.............if that makes sense, lol..............but the new tin, left open will do for the cabin and filling the gaps on the mouldings once made. in the meantime i'm sat in front of the computer waiting for the door bell to ring from the postie.....might be a package from foreign parts on the way, and can't hear the bell from my workshop when the music or tv are on. so I decided to look for the photo I have showing the plating lines of the steel/iron hulls [ no one has ever stated the real metal used for the hulls], and finally finding it in a book I have reproduced it as best I can, although in the original glass plate image in the book it shows much clearer........one can see the faint lines of the top two plate lines of the hull. these lines correspond with those clearly marked on the model plug that was really a very good modellers plug . although those lines have now been obliterated at bow and stern by filler, they can easily be reinstated now that I have the photo. the only other question is..........was this boat constructed with a welded hull, as looks to be a "weld line" in the photos or an overlap plate configuration with flush ground rivets.   |

|

| |

davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Jul 10, 2017 7:16 pm Mon Jul 10, 2017 7:16 pm | |

| hi neil , have you read the article in the engineer sept 1890, i have been looking at this over the past couple of years with the intention of building it myself, but with a single prop as i dont want to go down the road you are going.   . in the engineer it states that the hull was made of the very best steel procuarable was employed haveing been submitted to the severest cold tests. (the rivetting is a special feature of the boat). it states where torpedo boats has double rivetting, the duke of northumberland was triple rivetted and there is no single rivetted seam from stem to stern in the hull our deck fitting. if you want the full story and photos i will scan and send to you if you send me your email. hope this helps. david | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Jul 10, 2017 7:51 pm Mon Jul 10, 2017 7:51 pm | |

| please david...............i'll send via pm. thanks.

by the way, the James Steven no. 3 and no.4 plus the City of Glasgow were all single screw prop driven. |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Jul 10, 2017 8:12 pm Mon Jul 10, 2017 8:12 pm | |

| the boat in the preceding photos is the James Stevens, but can't see which one........the JS no.4 was the Padstow boat which was capsized and wrecked with the loss of 8 crew in April 1900. |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Jul 10, 2017 8:50 pm Mon Jul 10, 2017 8:50 pm | |

| just been playing with the photo on my computer and enlarged to 500% where you can for absolutely sure, see the actual plate joins of slight overlap both following the sheer of the boat and the vertical lines of the plates............the job just got more interesting and enjoyable..............I LOVE plating a hull. |

|

| |

davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Jul 11, 2017 8:34 am Tue Jul 11, 2017 8:34 am | |

| hi neil,

i have sent you the details hope you can read it as it is a very old news paper. also hope you have the details you need.

david

forgot to say scroll down to page 192 to 193 | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Jul 11, 2017 12:14 pm Tue Jul 11, 2017 12:14 pm | |

| cheers David.

I shall have a good read now. thanks. |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Jul 12, 2017 5:31 pm Wed Jul 12, 2017 5:31 pm | |

| |

|

| |

gribeauval

Master

Posts : 500

Join date : 2011-06-11

Age : 73

Location : West Yorkshire

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Jul 12, 2017 8:16 pm Wed Jul 12, 2017 8:16 pm | |

| Comming along nicely Neil.  | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Jul 12, 2017 8:44 pm Wed Jul 12, 2017 8:44 pm | |

| cheers mike........... the flange has set and been cut by jigsaw to the width required and then a coat of ronseal satin indoor varnish added.........let it dry overnight and then hopefully be able to give it another two coats tomorrow if this glorious weather holds. I can't get over how beautiful the fine lines of this lifeboat had.    |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Aug 07, 2017 3:59 pm Mon Aug 07, 2017 3:59 pm | |

| believe it or not, I really love this job that I have just started.....Plating a hull ready for moulding. there are 3 basic plating techniques used on a boat/ship and those are: 1] Butt plating, self explanatory where plates don't overlap, 2] Joggled plating, where inner and outer plates are used, and riveted, and 3] Overlapped plating, which is basically what clinker planking is on a wooden boat, but in steel or iron. The steam lifeboats used the 3rd method, where a row of plating starts close to the keelson, working down and round from there to the bulwark level in rows. a final row of plates being joggled in as would a king plank be on a deck, running down the length of the boat if no raised keel is fitted. The plates are started at the stern and keel and work forward, always staggered over the last row, like brickwork to give maximum strength against flexing of the hull. Its a slow job, but not tedious, and I find that if plates are cut identically at the same time for both port and starboard sides, you can't go wrong....famous last words, lol. I started the plating on this hull though by doing the hardest plate to glue in place because of it's shape. the centre plate forming the scoop . to do this though, I made an 80 gram paper plate first and glued in using PVA glue [used throughout the plating process], and then cut a similar plate from the 300 gram card used to simulate the plating. This plate glued in place, I started to plate the rest of the hull, from the stern, heading forward down the hull.            |

|

| |

davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Aug 07, 2017 4:49 pm Mon Aug 07, 2017 4:49 pm | |

| | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Aug 07, 2017 7:58 pm Mon Aug 07, 2017 7:58 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Aug 08, 2017 10:53 pm Tue Aug 08, 2017 10:53 pm | |

| two more rows of plates put on today. the black row has no significance, other than it was the next piece of card I picked up off the pile. each row takes about an hour to measure up, cut and glue to the boat. only 4 more rows to do, lol.   |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Aug 11, 2017 6:43 pm Fri Aug 11, 2017 6:43 pm | |

|

Last edited by nhp651 on Sat Aug 12, 2017 6:01 pm; edited 1 time in total |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Aug 12, 2017 12:16 pm Sat Aug 12, 2017 12:16 pm | |

| the end boxes have now been plated, and next onto the main cabin and well deck sides. this plug will be made from obeche and then plated.   |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Aug 12, 2017 2:45 pm Sat Aug 12, 2017 2:45 pm | |

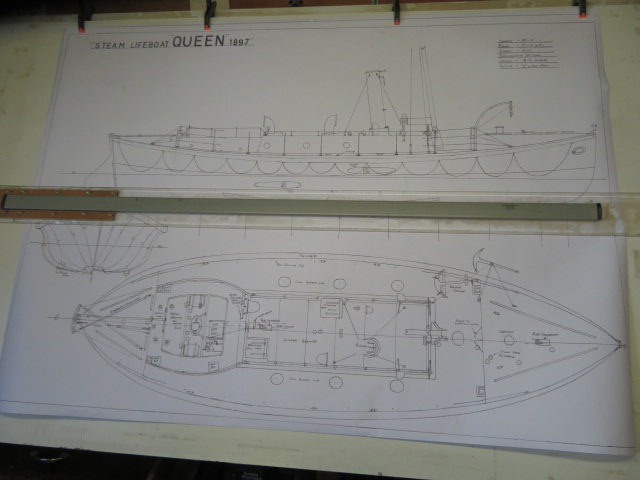

| You know things are getting serious when you mount your plans on the drawing board. However, after sitting on my chair and perusing both the hull and the plans, I came to one conclusion, either I or the printer in Blackpool had made a Whoopsie Daisies up. I took the original plans into the printer, (drawn at 1/2" to the foot) into Blackpool some weeks ago, and asked them to enlarge them by 200%, giving me the correct length of 56 inches on hull size. looking at the hull plug and then the enlarged plans, and backwards and forwards for a few minutes, I came to the conclusion that the plans showed a length far short of the 56" required...................ooooops.........in fact the enlarged size works out at around 1;18th scale................so thwarted..........wanted to get on with the main cabin today.............suppose I could manually enlarge the size from the 1;24th scale original plan, and stop moaning.  |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Aug 12, 2017 5:59 pm Sat Aug 12, 2017 5:59 pm | |

| start of the main cabin/engine cover. using obeche I cut the main block for the upper layer and four strips for the lower layer giving the full height of the cabin of 58mm.  |

|

| |

davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Aug 12, 2017 7:41 pm Sat Aug 12, 2017 7:41 pm | |

| hi neil, you have really caught the bug building this  you must be happy at your work. can i dare ask if you are going to show the riveting effect  our is that to hard. david | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Aug 12, 2017 9:01 pm Sat Aug 12, 2017 9:01 pm | |

| - davidjt wrote:

- hi neil,

you have really caught the bug building this  you must be happy at your work. can i dare ask if you are going to show the riveting effect you must be happy at your work. can i dare ask if you are going to show the riveting effect  our is that to hard. our is that to hard.

david there was no riveting detail on the hull, David.....it was all flush riveted and ground smooth apparently............. I'll have to look closer on the superstructure to see if there was any detailing, and if so, yes, I have a couple of paint pens for fabric painting that leave small dome heads on the paper which dry hard. |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Aug 13, 2017 3:01 pm Sun Aug 13, 2017 3:01 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Aug 14, 2017 2:26 pm Mon Aug 14, 2017 2:26 pm | |

| before and after sanding, ready for plating.........a good course 40 grade grit on the palm sander soon made mincemeat of the rough surface and now ready for plating.........now have to look at all the old photos of the vessels to see which edges of the cabin are sharp, and which are rounded.  |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Aug 15, 2017 10:44 pm Tue Aug 15, 2017 10:44 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Aug 15, 2017 11:53 pm Tue Aug 15, 2017 11:53 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Aug 25, 2017 2:16 pm Fri Aug 25, 2017 2:16 pm | |

| I should have been in Canada at this point in time with my daughter, taking a couple of Speedline Shannon kits to a friend in Calgary, but about a month ago I bashed my ankle on my work bench or car door, can't remember which , but although it hurt, I thought I had just bruised it, but didn't realise until a few days before I was due to fly out that I had not just bruised it, but broken a bone in my ankle , and the doctor told me it was very inadvisable because of my age and size [weight] to be sitting in the cramped confines of an aeroplane for a long haul flight, so have postponed the trip..........and therefore have, after getting bored and sitting on my posterior for a week, got on with the model. The inexorable slog towards getting the plugs ready for taking moulds is on. I gave the plugs several coats of cellulose sanding sealer and then 2 coats up to now of yacht varnish to give a hard finish. this will then be given a couple more and finally wet and dry paper used on them to smooth the plugs for moulding. I have also, because the hull will be a split mould in two halves, completed the spine/keel flange ready for fitting and moulding up to.      |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Aug 26, 2017 3:57 am Sat Aug 26, 2017 3:57 am | |

| Thought you were gunna build a paddler mate? |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Aug 26, 2017 1:37 pm Sat Aug 26, 2017 1:37 pm | |

| no matey............don't know enough about them...........that was the downfall with the ferry.......why it took me so long to build.

there was a design and model and mock up made in the late 1800's for a paddle driven lifeboat, and have seen a photo of it somewhere but can't find it anywhere........that would have made another interesting project. |

|

| |

Guest

Guest

|  Subject: "dirty deeds done dirt cheap" Subject: "dirty deeds done dirt cheap"  Sat Sep 16, 2017 2:45 pm Sat Sep 16, 2017 2:45 pm | |

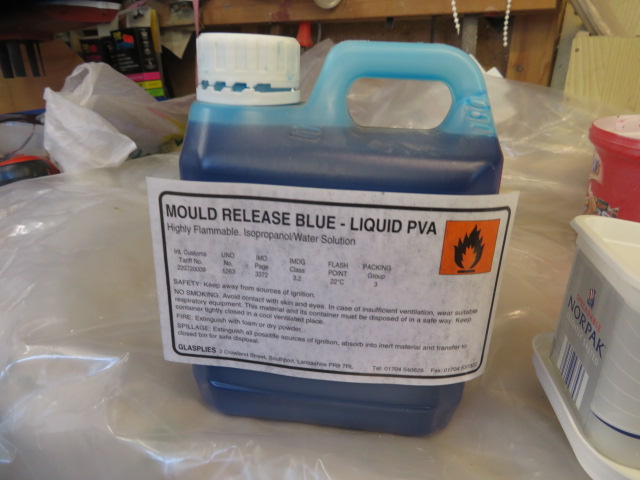

| took the trip down to Southport today for my GRP supplies...about 45 miles...........nearly had apoplexy when I pulled up outside Glasplies only to find a new company called TRICEL........and thought i'd had a wasted 3 hour reurn journey............. not to be put off I entered the inner sanctum and found that it was the good old Glasplies that I had known fo years, but with a new owner and name.... so anyone wanting to buy from them over the counter or by order/delivery they still go under both names for a while. anyway, I bought my stuff......... 20klo's of resin, 2.5 klo's white gell coat, blue release agent, release wax, catylist and chopped strand and surface tissue............got my silicon gloves, got my measure jugs.................am ready for blast off, once I have waxed up the plugs and put the flange on the hull plug............just need some disposable brushes from the pound shop, as cheaper than acetone for cleaning them...and more environmentally and lung friendly.      |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Sep 16, 2017 10:12 pm Sat Sep 16, 2017 10:12 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Sep 17, 2017 2:10 am Sun Sep 17, 2017 2:10 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Sep 17, 2017 1:24 pm Sun Sep 17, 2017 1:24 pm | |

| no mate..........'onist mister...........look at the phots dated 12th July....................it really was sunny, lol. |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Sep 17, 2017 7:43 pm Sun Sep 17, 2017 7:43 pm | |

| not much can be seen other than a dullness to the sheen on the plugs, but they have all been wet and dried with 180 and then 240 grade, before waxing up. Only another 8 coats of wax to go.............I want my mould to pop away from the plug easily and with no drama. I shall go through the stages of the mould making again for anyone new to this and have not read my previous builds. the release agent wax that is used for moulding is a NONE SILICON based wax, as silicon's can interact with polyester resins and cause rippling to the first layer......the waterproof gelcoat layer. this is the only waterproof layer to grp moulding, as the polyester resin is pervious to water ingress, especially salt water, and causes bubbling to the inner layers if exposed to water for too long.     |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 19, 2017 12:22 pm Tue Sep 19, 2017 12:22 pm | |

| THE three smaller plugs have now had blocks glued to the undersides so that they can be clamped into the workmate whilst laying up the grp. Next was to attach the flange. This was screwed to the deck level flange. In such a position it left small gaps between the flange and the keel, stem and stern post, and it was this that had to be rectified, but not before fixing firmly in place. To do so, I first placed some blobs of white tack adhesive "mastic" onto the side that will eventually be laid up as the first side. This was to limit movement from the centre line of the keel of the flange. Then blobs of white tack were placed on the "back side of the flange to hold in place, before filling the gaps between the blobs of whitetack with moulding plastecine. Back to the object side of the flange and hull I filled in the tiny gaps between flange and hull using small rolls of plastecine using a small chisel to press home into the gaps so close them up and give a near perfect seal between hull and flange to mould up to. I waxed the hull and flange up and once that has"dried" I will apply the blue PVA release agent, which in my mind is imperative for an easy splitting of the mould from the plug when ready, and also from mould to moulding.         |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 19, 2017 12:50 pm Tue Sep 19, 2017 12:50 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 19, 2017 5:01 pm Tue Sep 19, 2017 5:01 pm | |

| The blue, PVA release agent has been painted on this evening.......the final barrier between the plug and the mould which will help enormously in separating the two halves. the gel coat, pigmented white is going on this evening and I shall lay up the first half of the mould tomorrow,    the only thing that concerns me about moulding this relatively easy plug is the duct to the water intake. as it has been split down the centre by the flange, I'll have to be careful not to get an air bubbles into the corners of each half.  |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 19, 2017 7:06 pm Tue Sep 19, 2017 7:06 pm | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 19, 2017 7:09 pm Tue Sep 19, 2017 7:09 pm | |

| Looking good Neil. Hope to see lots of progress when I get back from, holiday.   Barrie | |

|

| |

Sponsored content

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  | |

| |

|

| |

| | STEAM HYDRAULIC LIFEBOAT |  |

|