| | STEAM HYDRAULIC LIFEBOAT |  |

|

|

|

| Author | Message |

|---|

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 19, 2017 7:43 pm Tue Sep 19, 2017 7:43 pm | |

| all I can say matey is I hope you have more sun than I got on my holiday in Scotland...............it rained EVERY single day............never done that in 18 years..........and I came away thinking what a waste of money..........may as well have stayed at home...

hope you not flying Ryan Airways, lol. |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 19, 2017 7:47 pm Tue Sep 19, 2017 7:47 pm | |

| Off to Germany Neil with Air Berlin who are bankrupt  Should be about as warm there as here, but the wine is better   Barrie | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 19, 2017 11:02 pm Tue Sep 19, 2017 11:02 pm | |

| is it hot air balloon then seeing as they are banko, lol...enjoy yourself mate. |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Sep 20, 2017 12:31 pm Wed Sep 20, 2017 12:31 pm | |

| After preparing and cutting all the chopped strand matting into squares, rectangles and 4" strips last night, I had a marathon none stop 2 hour session this morning laying up the first side of the hull mould. I am going to leave the cabin and end boxes until the hull mould is complete and trimmed up before I lay them up or I'm not going to have enough room in my workshop.   |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Sep 20, 2017 2:54 pm Wed Sep 20, 2017 2:54 pm | |

| I have cleaned up the overlay from the flanges and also taken the plastecine and white sticky mastic from the main flange, ready for taking it off later this evening. the garage heaters are working overtime to help hasten the curing of the first half mould, as I really want to get the gelcoat onto the second half this evening. I have also cut and split the matting ready for laying up tomorrow. I buy 450 gram chopped strand matting, as it is a little thick and unpliable when moulding a model hull.......but it is the same price as 300 gram matting. however, if you split the layers, it then becomes more pliable and you get half as much coverage again for the same price.    |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Sep 20, 2017 9:16 pm Wed Sep 20, 2017 9:16 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Sep 21, 2017 10:17 am Thu Sep 21, 2017 10:17 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Sep 21, 2017 1:52 pm Thu Sep 21, 2017 1:52 pm | |

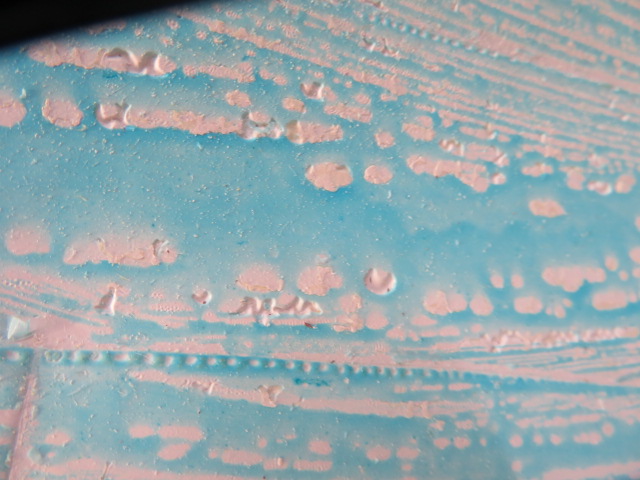

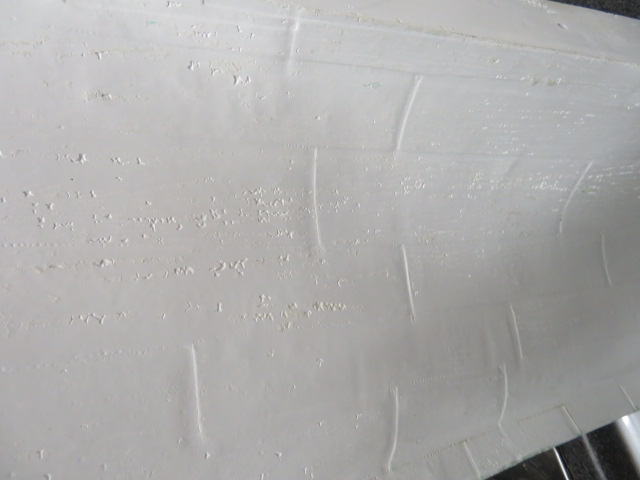

| I said at the start that this as with my other builds would be a "warts and all" build and if I make a mistake I would own up to it in order to help others not to make the same one. Well I made one big style. When I laid up the first half of the hull I cheapened myself by using some gelcoat that had been in a sealed tin for some time......in fact probably since I moulded the hull of the ferry nearly 4 years ago, on reflection......shelf life of such stuff once opened is a maximum 6 months under controlled conditions, and no way are the temperatures in my workshop controlled........but I hoped and prayed that there wouldn't be a reaction to using this on the first half......... Sadly my prayers weren't answered, and when I finally finished the mould this morning and then trimmed it up, I split it and removed it from the plug to find that the old gel coat had crinkled and left an uneven surface. there was a choice, leave it and when waxing up to put extra wax into the crinkles so that when the moulding is taken off it the raised particles can be sanded off or leave the second half attached to the plug and lay up a ew half to that. However the plug was now in a state and would need cleaning and probably wet and drying again before waxing again, and so I decided that as only a few sets of mouldings are going to be taken off by myself for friends, then they can sand down their own hulls to the perfection they want. But the moral is.........DON'T CHEAPEN YOURSELF AND USE OLD AND SHODDY MATERIALS...........it causes more work and expense in the end.    |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Sep 21, 2017 2:04 pm Thu Sep 21, 2017 2:04 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Sep 21, 2017 9:08 pm Thu Sep 21, 2017 9:08 pm | |

| have now cleaned off the blue release agent and found that the pitting in the gelcoat isn't as bad as I thought............t's mostly under the waterline................only joking, it's not as deep as I thought and mainly restricted to the bow area........... with liberal coatings of wax on the mould, the raised bits on the moulding, although numerous, won't need as much sanding off as first thought, so spirits are lifted a little..........may be a beer can be lifted as well as the spirits.  |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 26, 2017 11:43 am Tue Sep 26, 2017 11:43 am | |

| and the first hull moulding has been laid up this morning, 3 layers o 300gram chopped strand matting, and then the bulwark level trimmed off to the top of the flange. the moment to worry about is when I split the mould tonight after it has hardened and started to cure......see whether the mistakes of the gash gelcoat on the first half comes back to haunt me and rips the mould apart........   |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Sep 26, 2017 9:53 pm Tue Sep 26, 2017 9:53 pm | |

| |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Sep 28, 2017 3:35 pm Thu Sep 28, 2017 3:35 pm | |

| I have now readied the two end boxes for moulding, but waxing up, painting with PVA and glueing two blocks of wood onto the underside of each mould. These blocks are to clamp into the Black and Dekker workmate to hold them still whilst moulding. Will knock a couple out tonight. However, the cabin mould came out c r a p when I finally got to look at it......too many air bubbles in the gelcoat, which collapsed when waxing up, and so I have decided to make my cabin from 3mm ply, and offer templates to anyone wanting a set of mouldings..........it will be sturdier and easy to construct.     |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Sep 28, 2017 7:19 pm Thu Sep 28, 2017 7:19 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Sep 29, 2017 2:09 am Fri Sep 29, 2017 2:09 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Sep 29, 2017 6:00 pm Fri Sep 29, 2017 6:00 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Sep 30, 2017 11:16 am Sat Sep 30, 2017 11:16 am | |

| Just finished the second set of end boxes for the second hull.......had a bit of a dilemma as my daughter rung me just before I was due to start laying up and asked if I could pick her up from a friends house where she stayed last night after a night on the razz........so left me little time..... so I added another 2 mills of catalyst to the mix to send it off a little quicker........once laid up I then added a little accelerant.....a trick that my GRP tutor taught me when I was on a course building my 1st 16' Canadian style canoe in Canberra, Australia in 1976.......use a hot air gun once the mix has started to gell on the brush....used lightly, the extra heat won't damage the layup. So that is it..........two sets of mouldings predicted, two sets made, and now I can bolt up the mould to stop it from being damaged or deformed and then I can put the moulds and plugs away and get on with the building of the lifeboat with a little space to spare in the workshop.  |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Sep 30, 2017 6:00 pm Sat Sep 30, 2017 6:00 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Oct 01, 2017 11:36 am Sun Oct 01, 2017 11:36 am | |

| now that the hull has cured into it's permanent state for modelling I need to put on the belting..made from timber before I do anything else, for reasons later. I am going to try making them form 2 pieces of but jointed obeche 15mm square in section. because it is quite a lump of timber that has to bend I have first fixed the hull shape temporarily with pieces of timber, duct taped in place, and placed the obeche in a bath of hot water for a couple of hours to wet and make pliable.. then I shall take a piece at a time and offer it up to the hull an clamp in place. should it not bend to the bulwark shape, then I shall cut it again into 19 X 7mm strips and try laminating the belting in two parts. what I don't want to do is cut the timber cross wise to aid bending.    |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Oct 02, 2017 9:03 pm Mon Oct 02, 2017 9:03 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Oct 02, 2017 10:30 pm Mon Oct 02, 2017 10:30 pm | |

| both layers of the belting are now clamped up and drying out, to take a reasonable shape. once dry, the outer layer will be glued to the inner layer first to keep it stable and to the position akin to what it is now. oh it feels good to have a few clamps.    |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Oct 04, 2017 7:21 pm Wed Oct 04, 2017 7:21 pm | |

| The starboard sde belting has been removed now the glue adhering the two strips together has set. the belting has kept much of it's form and curve. the hull has been sanded smooth and 2.5 mm holes drilled into the hull centrally along the flat face of the upper bulwarks to take the 1/2" x6 screws. the hull was wiped with a damp cloth and the glue, called Gater Glue and totally waterproof, so it says lol [similar to gorilla glue] was applied to the timber. it was reclamped up to the hull and screwed up tight to the grp moulding using the screws from the inside. hopefully I'll get the other side on to the hull tomorrow.........going to give it a good enough of time to set solidly.     |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Oct 05, 2017 9:34 am Thu Oct 05, 2017 9:34 am | |

| i'm cracking on with this at the moment as I just want to get a few basics done for a forthcoming show in Blackpool near home in 2 weeks time........just need to get the belting on, and the deck beams in plus the end boxes on......... the first side has now been glued on and set. it has also been screwed in place from the inside of the hull. on to the second side now, but before I do.......off down to the tool shop to get a decent cross head screw driver, as the one I have is knackered and keeps slipping out of the screw.    |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Oct 05, 2017 11:41 am Thu Oct 05, 2017 11:41 am | |

| second side on, the glue is foaming, so at least working. I have 4 G cramps and as many spring clamps on the belting as will fit.......no space for any more so a good universal grip right the way along.........if you have them, use them............... no good leaving gaps of lesser pressure at places where the grip will be less........... and in the heated workshop hopefully I'll be able to start screwing it on for total bonding later tonight, and as each clamp taken off I'll put a screw in to hold the area tight.  |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Oct 05, 2017 1:59 pm Thu Oct 05, 2017 1:59 pm | |

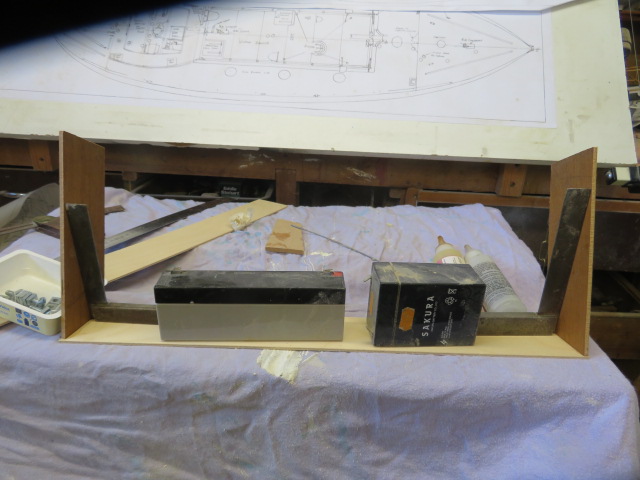

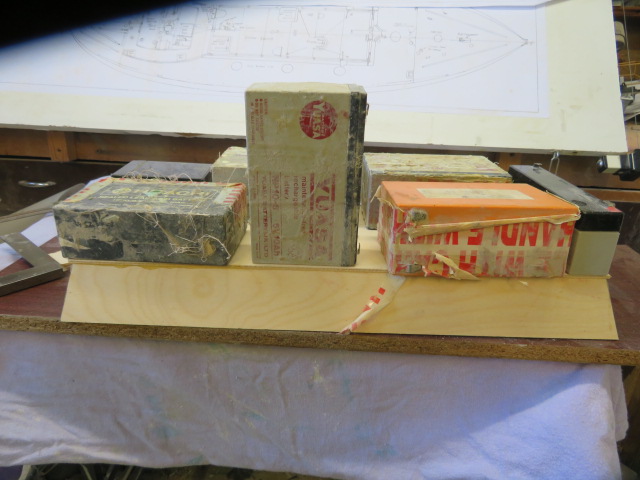

| Sadly the mould I made for the main cabin was a flop.......more gaps between gelcoat and matting than a Swiss gruyere cheese and so it went in the bin, and so I decided to make the cabin from 3.5mm ply, and here is the first part of the construction.....main uprights made first using my sliding bevel to get the angles of the ends correct, cutting on a band saw and then using epoxy to glue the 4 walls and then the Gator glue to fix the top down. Weighted down with old batteries it has been left to set till later. didn't realise just how much ply it would take...........used a whole 2' sheet of 3.5 ply that arrived this morning........none left now to make the deck surrounds..........7 quid for a cabin............must be getting old moaning about that xpense, lol.    |

|

| |

Guest

Guest

| |

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Oct 06, 2017 8:48 pm Fri Oct 06, 2017 8:48 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Oct 08, 2017 2:30 pm Sun Oct 08, 2017 2:30 pm | |

| saw this amazing little bit of kit on mayhem, and I have just spoken to the guy via phone, and am taking the boat over to him week after next to discuss using two pumps running off brushless motors [ one for forward propulsion and one for reverse, or one single pump with a manifold. the guy is an engineer and 3d prints the details and then casts them in his own foundry........so I'm hoping that he can come up with a specifically designed unit for the boat.  |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Oct 08, 2017 2:32 pm Sun Oct 08, 2017 2:32 pm | |

| back to the actual building.......I have cut the guides down for the end boxes to glue on to, and cut the deck support beams running fore/aft, but haven't glued those in just yet.  |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Oct 08, 2017 2:43 pm Sun Oct 08, 2017 2:43 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Oct 08, 2017 2:48 pm Sun Oct 08, 2017 2:48 pm | |

| I then put onto the two end walls, the guides for the side walls to fit into, which will be seen to work later. they were made from 5mm ply, bevelled one edge to take the wall. then support lip for the removable floor was glued in to the underside of the structures access hole. finally the side floors were thickened by a second layer of 3,5mm ply, which is what the main floor is made from, so that the side walls have ample gluing surface to attach to..............all using waterproof aliphatic resin quick grab glue and plenty of clamps.     |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Oct 08, 2017 2:59 pm Sun Oct 08, 2017 2:59 pm | |

| |

|

| |

Guest

Guest

| |

| |

Guest

Guest

| |

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Oct 10, 2017 6:29 pm Tue Oct 10, 2017 6:29 pm | |

| You're racing along with this one Neil   Barrie | |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Oct 10, 2017 8:53 pm Tue Oct 10, 2017 8:53 pm | |

| I am absolutely amazed just how easily it is going together Barrie........no fiddly bits to fabricate like wooden effect cockpits, small amount of fittings to make and everything big and chunky...........I am also enjoying building something that I have wanted to buil for many years.  |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

| |

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Oct 11, 2017 12:34 pm Wed Oct 11, 2017 12:34 pm | |

| I must admit I am happiest when building a lifeboat, matey......feel in my own world and element, and can't wait to get back into the build each day.

having said that have been running my daughter around this morning so won't be back on it till this afternoon/evening at the earliest. |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Oct 11, 2017 4:11 pm Wed Oct 11, 2017 4:11 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Oct 11, 2017 8:00 pm Wed Oct 11, 2017 8:00 pm | |

| and now been glued up using very strong gaffa tape and 15 minute 2 part epoxy.......shall leave that overnight to set, and then filled on the outside, but with some grp matting and resin on the inside..  |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Oct 12, 2017 6:54 am Thu Oct 12, 2017 6:54 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Oct 12, 2017 10:19 am Thu Oct 12, 2017 10:19 am | |

| thanks guys......appreciate the comments. I have been at it again.........before taking off the tape and pressure from the bilge keels, this morning I cut some strips of fine surface tissue and laid them over the steel pegs and holes on the inside of the hull, and sealed in with some polyester resin. I put 4 layers of tissue over the steel pegs/holes to give good purchase and holding power. hopefully the bile keels will now be rock solid and secure. I also, whilst I had some resin mixed, put multiple strips of surface tissue over the top end of the water scoop tunnel on the inside to build up a little thickness to eventually take the inlet tubes for the pumps, because as yet the diameter of these hasn't been chosen.     |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Oct 12, 2017 7:40 pm Thu Oct 12, 2017 7:40 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Oct 13, 2017 4:08 pm Fri Oct 13, 2017 4:08 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Oct 13, 2017 6:29 pm Fri Oct 13, 2017 6:29 pm | |

| I cannot believe that it has only been two weeks since I took the mouldings I am working on out of the moulds. it has been a quicker build so far than any kit I have ever built. today, and probably the last bit of work on it tonight I fitted the front end box.........using polyester car body filler, smearing it on the inside leading edges of the box and placing it onto the flanges running around the inside of the hull to locate it. I glued the lower wooden part of the bulkhead to the deck cross beam using waterproof glue. this I'll leave to set until tomorrow and under weight from batteries. then I'll fill the gaps between the top and deck. whilst this was setting I inserted a plastic guide into the aft end box for the servo arm linkage, and set with cyano to begin with. that's it for today.......going to have tea and a beer.     |

|

| |

Sponsored content

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  | |

| |

|

| |

| | STEAM HYDRAULIC LIFEBOAT |  |

|