| | like a kid in a sweet shop |  |

|

+8alw zetec Thornej raaartygunner Specialbuilder davidjt gribeauval Roadrunner 12 posters |

|

| Author | Message |

|---|

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sun Aug 19, 2018 9:33 pm Sun Aug 19, 2018 9:33 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Aug 20, 2018 4:23 pm Mon Aug 20, 2018 4:23 pm | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

| |

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Aug 20, 2018 6:14 pm Mon Aug 20, 2018 6:14 pm | |

| cheers barrie…….

been a slog I can tell you...……….and just about run out of propane...……...mind you, the bottle has lasted 5 or more years so far. |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Aug 20, 2018 7:21 pm Mon Aug 20, 2018 7:21 pm | |

| |

|

| |

battleshipbuff

Gunner

Posts : 174

Join date : 2012-03-16

Age : 78

Location : Cornwall

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Tue Aug 21, 2018 12:21 pm Tue Aug 21, 2018 12:21 pm | |

| That is some soldering there Neil, looking good though. It all looks like it's coming together very nicely. Keep up the brilliant work, and I expect you are cussing me, just like gribeauval was, because of the burnt fingers lol.

Mick F | |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Thu Aug 30, 2018 10:08 pm Thu Aug 30, 2018 10:08 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Aug 31, 2018 1:14 am Fri Aug 31, 2018 1:14 am | |

| |

|

| |

Thornej

Deck Hand

Posts : 4

Join date : 2017-08-20

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Aug 31, 2018 4:14 am Fri Aug 31, 2018 4:14 am | |

| | |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Aug 31, 2018 12:26 pm Fri Aug 31, 2018 12:26 pm | |

| thanks guys......just off to the brazing hearth now...……..this is where the swearing and cursing starts. lol |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Aug 31, 2018 7:25 pm Fri Aug 31, 2018 7:25 pm | |

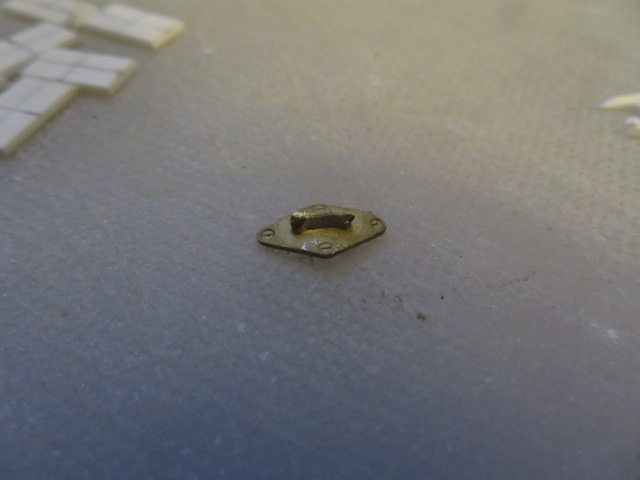

| stern rails finally silver soldered to the centre brass cast fitting.....took some doing as the fitting acted as a conduit to loose heat rapidly, but got there in the end. just a good clean up and a little filing of excess solder and flux and they'll be ready for a hot bath to get rid of grease, and then their "feet" round discs on the bottom of the stanchions.  |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Sep 03, 2018 12:48 am Mon Sep 03, 2018 12:48 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Sep 03, 2018 1:00 am Mon Sep 03, 2018 1:00 am | |

| how ya feeling matey..……….hope you getting over that virus you've had. |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Sep 03, 2018 1:06 am Mon Sep 03, 2018 1:06 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Thu Sep 06, 2018 5:08 pm Thu Sep 06, 2018 5:08 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Sep 07, 2018 6:25 pm Fri Sep 07, 2018 6:25 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Sep 08, 2018 2:40 am Sat Sep 08, 2018 2:40 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sun Sep 09, 2018 9:40 pm Sun Sep 09, 2018 9:40 pm | |

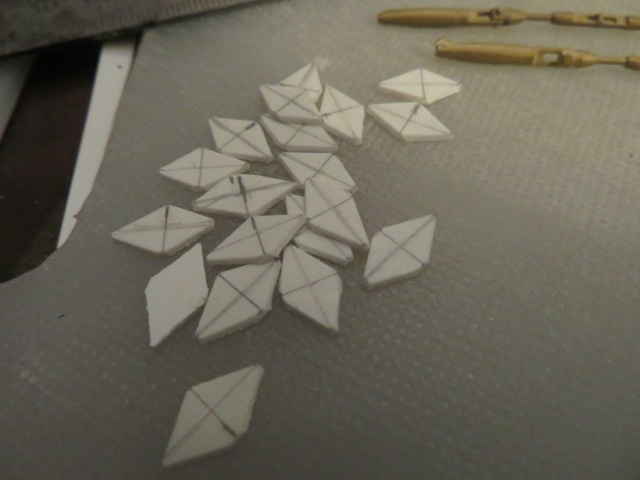

| I decided today to snip all of the railing turnbuckle fittings from their moulded tracks......these fittings are made from cast brass and so quite strong...….stronger than I could make from plastic and brass and no matter how much thought and fabrication I could muster, there is absolutely no way I could get them anywhere near as those supplied in the fittings kit....just one slight problem though...the diamond shaped fixing brackets on the ends of the turnbuckles at either end of the deck housing safety lines are cast wrongly and lie at 90* to what they should be.....so out again came the snips and I cut them away from the bracket, with the intention of cleaning them and the "shackle" attached to the brass fitting and redrilling both the shackle and the diamond plate and then drilling for a new loop of brass wire to make the bracket lie correctly longitudinally with the wire lifeline....and so I started filing one of them with a diamond tipped needle file...……the bracket being so small at 12 x 7 mm I tried holding with my fingers and then some circlip pliers and soon...…...disaster, the 1st one pinged out of my grip onto my workshop floor and lost into oblivion for ever more...…….ohhh sheet, or words to that magnitude...……….what to do, as I now have only 7 instead of 8 diamond brackets...….sod it...…...I reverted to my old stand in, and cut a number, enough to cover all the brass brackets and more besides...….and after they are all painted chromium, who will ever know, other than you lot, and the millions that read these threads, lol...…onwards and upwards.      |

|

| |

Thornej

Deck Hand

Posts : 4

Join date : 2017-08-20

|  Subject: Pulpit rails Subject: Pulpit rails  Tue Sep 11, 2018 7:57 am Tue Sep 11, 2018 7:57 am | |

| Hi Neil,

Great work!

A question - how do you solder additional rails without the previously soldered ones coming apart?

Thanks

Cheers

Jeff | |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Tue Sep 11, 2018 8:11 am Tue Sep 11, 2018 8:11 am | |

| - Thornej wrote:

- Hi Neil,

Great work!

A question - how do you solder additional rails without the previously soldered ones coming apart?

Thanks

Cheers

Jeff hi jeff, I use silver soldering for almost all my work these days with a portable brazing hearth made from a product called Vermiculite able to take temperatures up to 1600C...…...and the heat from a Sievert propane pencil tipped torch...……..temperature is very localized to the point you are soldering and as soon as you remove that heat from the immediate location the solder sets, meaning that you can solder both sides of a bar without the other side being liquified...……..no good for brass of 1mm or less, as the heat melts it to a blob. I gave up soft soldering years ago in favour of silver soldering...……..as it is a whole lot stronger and doesn't come apart if knocked...……….however I am about to buy some liquid soft solder paste so that I can use a low heat from a kitchen flambé torch to solder the thin life belt holders...……..but think i'll take templates of the parts before I do, in case I melt them lol. |

|

| |

Thornej

Deck Hand

Posts : 4

Join date : 2017-08-20

| |

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Tue Sep 11, 2018 9:23 am Tue Sep 11, 2018 9:23 am | |

| no problem.  |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Tue Sep 11, 2018 9:29 am Tue Sep 11, 2018 9:29 am | |

| What diameter silver solder wire do you use Niel, and what flux is appropriate???????????? |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Tue Sep 11, 2018 9:46 am Tue Sep 11, 2018 9:46 am | |

| the diameter isn't really the governing factor Damien, although the stuff I use is around 1.25mm dia...…...silver solder comes in differing melt points unrelated to the diameter of the rod...……….and I was given a bundle of the same dia rod some years ago which will last me a lifetime, lol.....and I haven't a clue as to what temperature it melts at, sorry. |

|

| |

Guest

Guest

| |

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Tue Sep 11, 2018 1:45 pm Tue Sep 11, 2018 1:45 pm | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Tue Sep 11, 2018 5:31 pm Tue Sep 11, 2018 5:31 pm | |

| - nhp651 wrote:

- Thornej wrote:

- Hi Neil,

Great work!

A question - how do you solder additional rails without the previously soldered ones coming apart?

Thanks

Cheers

Jeff Jeff There is an alternative to using silver solder for which you need a big heat source. I use soft solder and to prevent melting one joint whllst soldering the next I use heat sinks on either side of the joint. These can be as simple as crocodile clips, or larger metal spring clips. Barrie | |

|

| |

Thornej

Deck Hand

Posts : 4

Join date : 2017-08-20

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Wed Sep 12, 2018 8:33 am Wed Sep 12, 2018 8:33 am | |

| Thanks Barrie   Cheers Jeff | |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Sep 14, 2018 11:08 pm Fri Sep 14, 2018 11:08 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sun Oct 28, 2018 6:17 pm Sun Oct 28, 2018 6:17 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Oct 29, 2018 12:38 am Mon Oct 29, 2018 12:38 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Nov 30, 2018 9:07 pm Fri Nov 30, 2018 9:07 pm | |

| I am also building my friends semi kit of a Shannon by models by design along side my speedline models...……..but there are a few tricky bits on that boat...….the first being that the deck iglued onto the hull, unlike the speedline models one where the full deck is removeable. this causes problems in that the jet drives and motors are hidden under the aft part of the deck...… so today, I resorted to butchery and cut a rather large hole in the stern end to allow access. then I began to rectify this by putting in a watertight flush hatch. first by lining the hole with a wall, exactly the same size as the hole. onto the bottom rim of these "downstands" I made a "baseplate" circumnavigating around the hole with a final "upstand" running around that outer rim. this forms a channel running around the perimeter of the hole. once the hatch lid is cut to size, it will have a timber rim, the same thickness but for a mm each side of the hatch lid which will fit into the channel, thus forming a capillary block of water ingress through the hatch. as it is made from timer, it is held in place using a barrier of Vaseline[petroleum jelly] also adding to its water integrity. I have used this method for making flush watertight deck hatches many times with not a single drop of water getting in to the hull from that area.     |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Nov 30, 2018 10:52 pm Fri Nov 30, 2018 10:52 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Dec 01, 2018 12:42 am Sat Dec 01, 2018 12:42 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Dec 01, 2018 12:51 am Sat Dec 01, 2018 12:51 am | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

| |

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Dec 01, 2018 12:57 pm Sat Dec 01, 2018 12:57 pm | |

| CHEERS GUYS......THESETWO MODELS ARE SO FRUSTRATING......NO DECENT PLANS, ABSOLUTELY NO INSTRUCTIONS. you may as well build the whole thing from scratch and make everything as you go along...…….but we shall persevere. the base of the hatch has been glued in now and cramped up. the lid to the hatch has also been cut to size and shape and the retaining frame that slots into the base to form the waterproof break has also been fitted. this was glued using 2 part epoxy whilst the base was glued using waterproof aliphatic resin wood glue, taking longer to set, but giving a greater bond wood to wood.    |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Dec 01, 2018 4:42 pm Sat Dec 01, 2018 4:42 pm | |

| |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sun Dec 02, 2018 5:13 pm Sun Dec 02, 2018 5:13 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Dec 03, 2018 2:59 am Mon Dec 03, 2018 2:59 am | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Mon Dec 03, 2018 11:48 pm Mon Dec 03, 2018 11:48 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Fri Dec 07, 2018 3:07 pm Fri Dec 07, 2018 3:07 pm | |

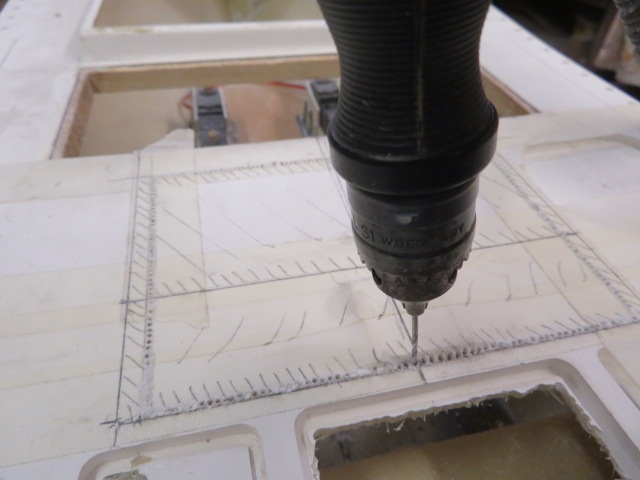

| people are always asking how one cuts out holes in bulwarks, windows recesses etc...……...and I am amazed when someone tells them to go and buy a hole cutter for a job that they will probably only ever use that hole cutter once in their modelling lives, and yet pay 20 - 30 quid for it to lay idle for the rest of its days, collecting dust...……… especially when most modellers possess the best hole cutter that they can own, with innumerable sizes and shapes that they could ever wish...…….an electric drill, drill bits and a bit of common sense.... the rest can be told in pictures.    ream out the piece by using the shaft of the drill cutting between holes   and then using small 6" files...….file and then sand to the lines, and for the curved corners, use some rolled up abrasive paper. |

|

| |

Guest

Guest

| |

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Dec 08, 2018 5:09 pm Sat Dec 08, 2018 5:09 pm | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Dec 08, 2018 5:38 pm Sat Dec 08, 2018 5:38 pm | |

| Looking Good Neil - lots of intricate brass work there   Barrie | |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Dec 08, 2018 11:39 pm Sat Dec 08, 2018 11:39 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  Sat Dec 08, 2018 11:55 pm Sat Dec 08, 2018 11:55 pm | |

| the stern pulpit rail was the trickiest with lots of holding with the stands with crockodile clips...…..third hands I think they are called, but got there in the end.....…….would have taken me 3 times as long had I not used silver soldering and a propane gas torch.... anyway...……..I put a request for help on mayhem over 4 hours ago about how the interior of the cabin goes together from the 3 vac formed pieces of plastic…...even emailed and messaged Adrian gosling..... over 4 hours ago...…...and in the end...…….the BP rose, mercury boiled and I had to post...….. 53 reads , 33 views of the interior...….over 2 dozen kits at both 12th and 16th scale sold with these interiors, and not a single offer of help...……...c'est la vie.

its at times like this that I have no other words to say other than, I now know why such helpful people as Inertia, aka Dave Milbourn and Stavros turned their backs on this site...

Anyway, don't worry folks……….I've sorted it.   SO what I did was to separate by my usual brute force and butchery, the cabin from the deck and started to fit the interior upside down, and work backwards....….my usual state anyway, lol...…….and i'll get there in the end...…… pick shows the interior tray sat inside but not fit...………...for eventually it has to have all seats, radars etc fitted...…...a model in itself...…….but now I know what I am doing and sod the rest...…...they can fend for themselves.only on here will you see it...……..oh ye, the yank site as well, lol.  |

|

| |

Sponsored content

|  Subject: Re: like a kid in a sweet shop Subject: Re: like a kid in a sweet shop  | |

| |

|

| |

| | like a kid in a sweet shop |  |

|