| | My Eileen |  |

|

+3davidjt barriew troutrunner 7 posters |

|

| Author | Message |

|---|

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: My Eileen Subject: My Eileen  Tue Oct 28, 2014 11:30 pm Tue Oct 28, 2014 11:30 pm | |

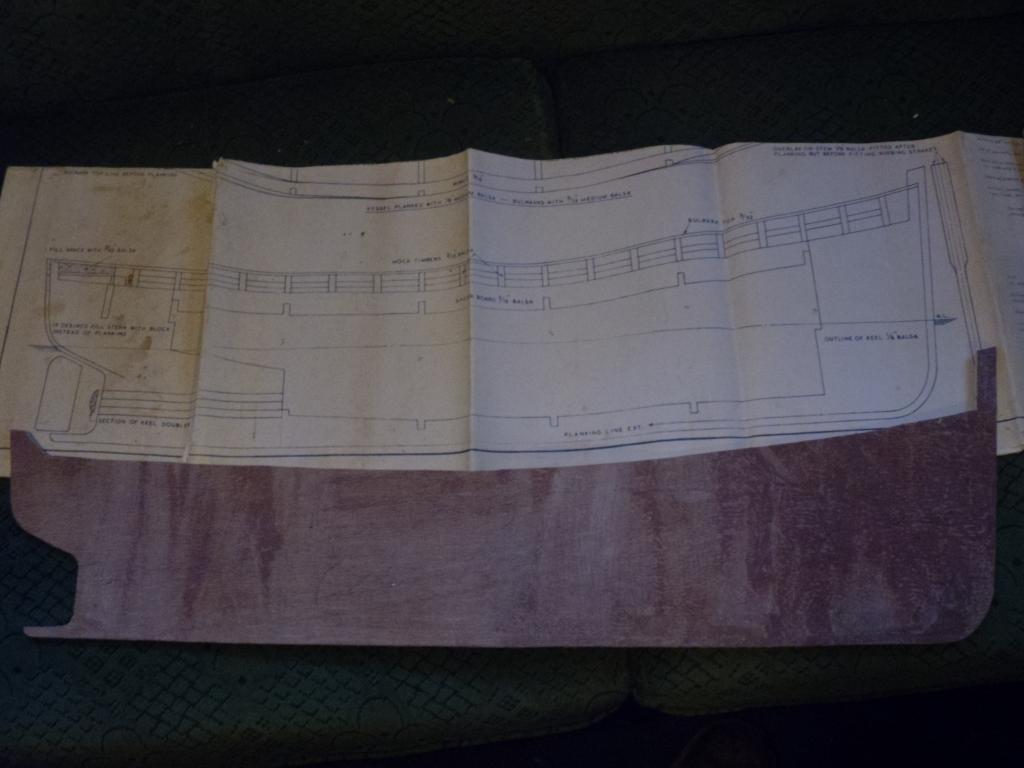

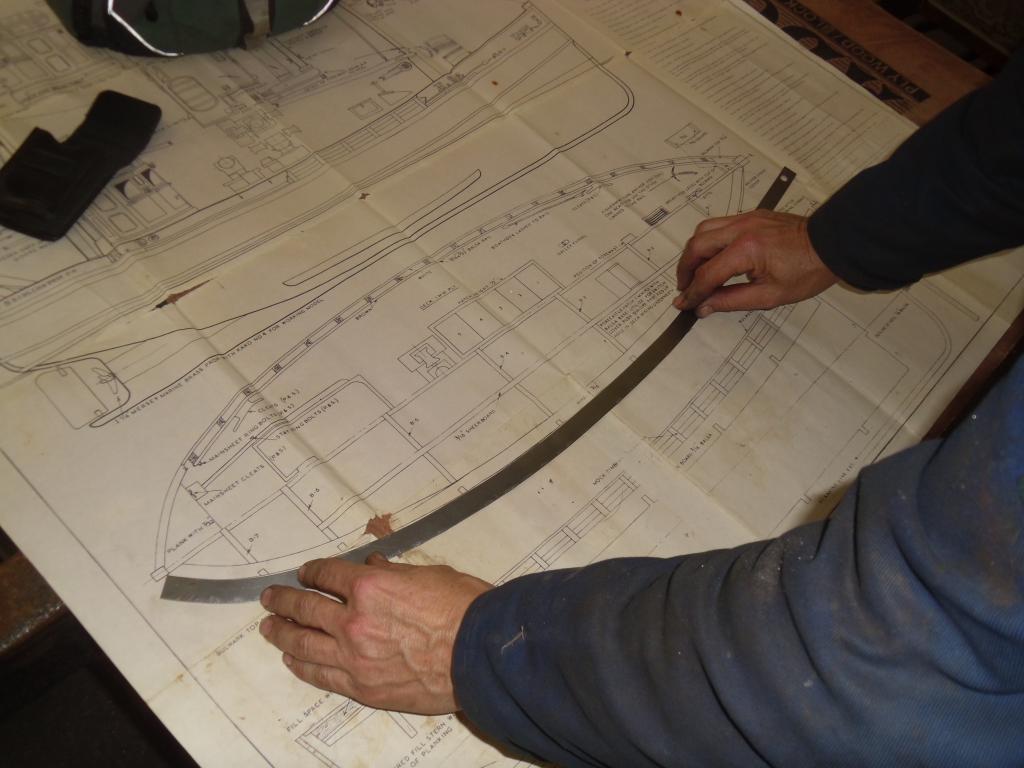

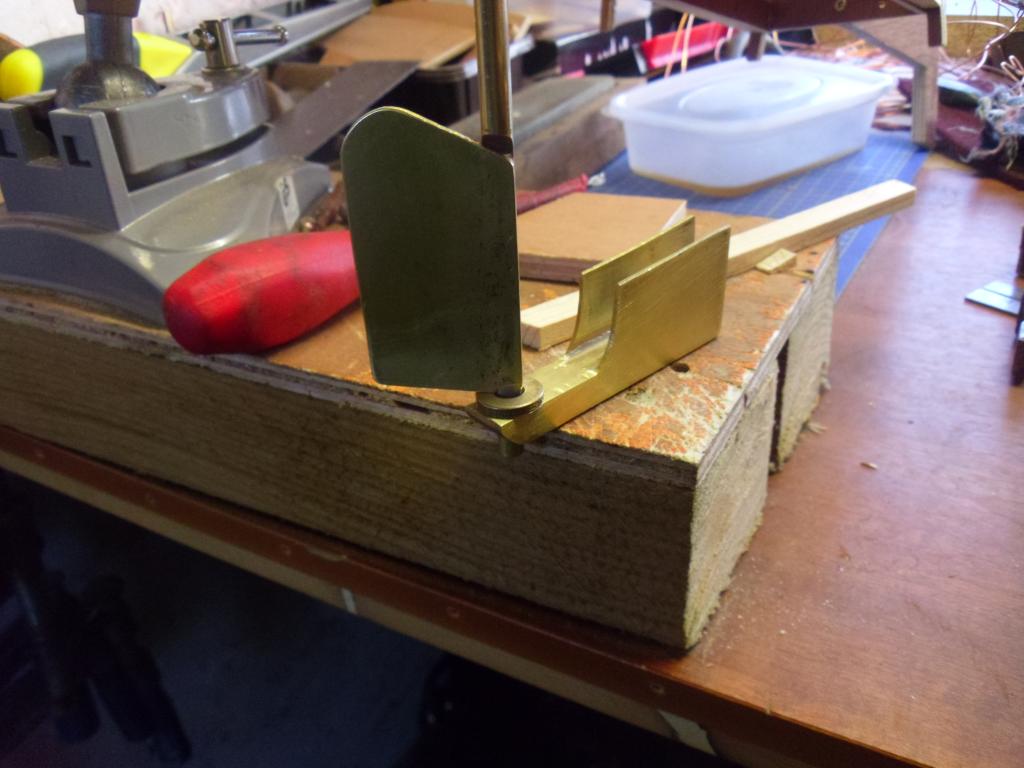

| I sought of found with this modelling lark that you can run out of things to do, so, the reason I started in the first place was because I had a plan for MFV Eileen, had it for many, many years, started it twice and for reasons unknown didn't get very far. I was advised by others to buy a kit, which would be an easier build, hence the Fast Patrol Launch build. Here is a quick catch up to where I am now. I have a Burgess Band Saw and used it to cut out my basic shapes.   The keel/centre board and sheer boards are cut out.  And cleaned up  Fitting the stern tube and keel doublers.  Trial fit of a few bits.  I just love elastic bands, free from my postman   Made a little mistake but I will repair and it won't be seen anyway.  My friend made me some profile gauges for the sides on his Ekold shrinker/stretcher.   I must have lost a few photy's somewhere  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Tue Oct 28, 2014 11:46 pm Tue Oct 28, 2014 11:46 pm | |

| | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Oct 29, 2014 8:04 am Wed Oct 29, 2014 8:04 am | |

| Hi all, a little help required, I don't know what motor or servo for the rudder to use, some advice from you knowledgeable folk for a novice on which type and size and where do others get these bits from please.  | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Oct 29, 2014 8:41 am Wed Oct 29, 2014 8:41 am | |

| For a motor I would imagine a 545 would be ideal - it looks as though it will be a substantial model, but you are not looking for great speed. As for a servo, I find the miniature ones have sufficient torque for non-racing models up to 30 or so inches, but a standard servo would do fine. As for supplier, then either Cornwall Model Boats or Component Shop can supply both the above, and are very reliable in my experience. The International Model Boat Show at Leamington Spa is coming up soon. If you are able to visit that you will find all you need there (and more  ) Barrie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Oct 29, 2014 7:09 pm Wed Oct 29, 2014 7:09 pm | |

| - barriew wrote:

- For a motor I would imagine a 545 would be ideal -

As for a servo, I find the miniature ones have sufficient torque for non-racing models up to 30 or so inches, but a standard servo would do fine. As for supplier, then either Cornwall Model Boats or Component Shop can supply both the above, and are very reliable in my experience.

The International Model Boat Show at Leamington Spa is coming up soon. If you are able to visit that you will find all you need there (and more  ) )

Barrie What does 545 stand for, probably obvious but not to me the novice.I'm not sure how I tell a standard from a Miniature servo eitherforgive my ignorance, all the bitts for the "Fast Patrol Launch" came with it, so have not many clues | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Oct 29, 2014 7:17 pm Wed Oct 29, 2014 7:17 pm | |

| Paul,

A 545 motor is a 540 series motor with 5 poles. These are more efficient than straight 540s which only have 3 poles. Athough not marked as 545, this is a 5 pole motor http://www.componentshop.co.uk/540-standard-dc-motor.html

This ia a micro servo http://www.componentshop.co.uk/9g-micro-servo-3v-6-0v.html whilst this is a standard one http://www.componentshop.co.uk/25g-standard-servo.html

The difference is the physical size, as well as the power and operating speed.

Hope this clarifies things a bit.

Barrie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Oct 29, 2014 8:13 pm Wed Oct 29, 2014 8:13 pm | |

| Thanks Barrie, got that now, next question, what motor Bracket is required  I'm sure when I get onto boat build 3 I will know a little more, I'm planning that one now, a "Great Lakes Freighter"  | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Oct 29, 2014 8:15 pm Wed Oct 29, 2014 8:15 pm | |

| You can get a bracket designed for the motor - check the web site, there is an option to buy the motor with a mount I believe.

Barrie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Oct 29, 2014 10:00 pm Wed Oct 29, 2014 10:00 pm | |

| Many thanks Barrie, beginning to get it now  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Oct 30, 2014 9:00 am Thu Oct 30, 2014 9:00 am | |

| Ok, assuming I go with this 540 series motor with 5 poles, what battery power do I/can I use ?

And what speed controller would I need ? | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Oct 30, 2014 11:15 am Thu Oct 30, 2014 11:15 am | |

| Paul,

A 10 or 15 amp ESC would be fine. That is a very low current motor. As for battery, 6 to 12 volts depending on your preference for NiMh or SLA - I wouldn't recommend LiPo for this application.

Barrie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Oct 30, 2014 1:59 pm Thu Oct 30, 2014 1:59 pm | |

| I have some batteries for the other project and have posted a question in the electrics section to keep this thread a little cleaner, must go back to work now, I'm late  as usual........... | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sun Nov 02, 2014 11:08 am Sun Nov 02, 2014 11:08 am | |

| | |

|

| |

davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sun Nov 02, 2014 12:01 pm Sun Nov 02, 2014 12:01 pm | |

| looking good  are you going to plank on frame it with what material  david | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sun Nov 02, 2014 8:30 pm Sun Nov 02, 2014 8:30 pm | |

| Hi David, I was given an old wardrobe which was edged with some hardwood, some teak like in colour (thought I would save this for decking) and some lighter coloured stuff, not sure what though. I have already cut the lighter coloured bits into some planks of 2mm thickness but still have more if I need to correct my mistakes. I have just uploaded some photy's of the planking, will put it in a post in a bit  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

| |

| |

Oldsmokey

Gunner

Posts : 120

Join date : 2014-10-10

Age : 86

Location : Bournemouth, Dorset. UK.

|  Subject: Re: My Eileen Subject: Re: My Eileen  Tue Nov 04, 2014 11:29 am Tue Nov 04, 2014 11:29 am | |

| Postman, elastic bands! You’re lucky ours must sell his because we never get any left around. Wardrobe recycling again, I think you do more than you are telling us.  Another nice build, more piccy’s please.  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Tue Nov 04, 2014 12:20 pm Tue Nov 04, 2014 12:20 pm | |

| - Oldsmokey wrote:

- Postman, elastic bands! You’re lucky ours must sell his because we never get any left around.

I asked the relief postlady for a few as they would be handy and they just kept coming, now I have a carrier bag full, I had to ask them to stop leaving then as I think I must have as many as the Post Office do.  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Tue Nov 04, 2014 1:53 pm Tue Nov 04, 2014 1:53 pm | |

| I found I had a little discrepancy in the deck level, about an eighth of an inch from one side to the other which I thought a little to much. So I made a board up for the planking job which has pulled it back within limits, not sure how others build boats like Eileen, I must admit I am making all this up as I go along, please comment if you use a different method. Angle irons screwed to the bottom of a piece of ply.  chocked under and clamped on top.   | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Mon Nov 10, 2014 7:51 pm Mon Nov 10, 2014 7:51 pm | |

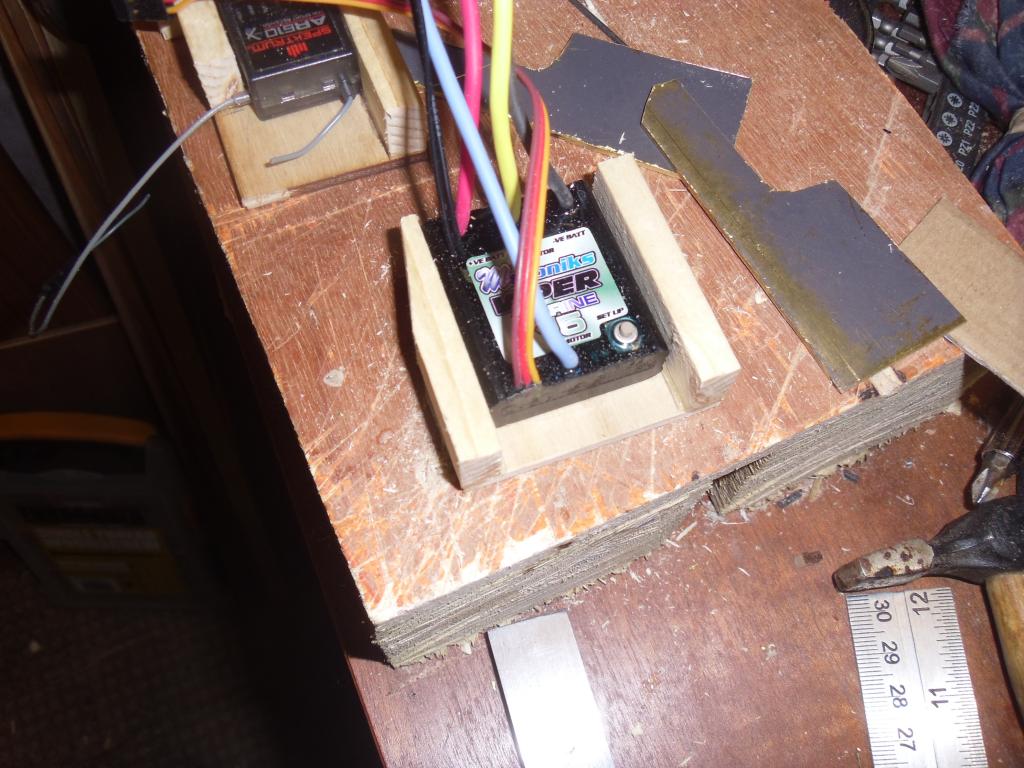

| A little more done here, I have put in the motor mounting shelf, U?J on the prop in reediness.  Also the start of the battery shelf.  Not a great deal I can do now until I see an engineering pal of mine who is going to make up a two part rudder assembly for me. The rudder shaft is to have a slot machined to take the rudder and will be secured with a couple of grub screws, much like a throttle assembly of a carburettor. | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Tue Nov 11, 2014 10:16 pm Tue Nov 11, 2014 10:16 pm | |

| | |

|

| |

davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Nov 12, 2014 3:32 pm Wed Nov 12, 2014 3:32 pm | |

| | |

|

| |

Oldsmokey

Gunner

Posts : 120

Join date : 2014-10-10

Age : 86

Location : Bournemouth, Dorset. UK.

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Nov 12, 2014 4:23 pm Wed Nov 12, 2014 4:23 pm | |

| Coming along very nicely indeed Paul. My wife  gave me a present yesterday just to cheer me up. A large bag of elastic bands. My Son came round just to take the lift! with a load of cable ties. All different colours. Suppose it makes a change from grapes. | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Nov 12, 2014 6:44 pm Wed Nov 12, 2014 6:44 pm | |

| Thanks chaps, it's nice to get a bit of encouragement  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Nov 13, 2014 7:48 pm Thu Nov 13, 2014 7:48 pm | |

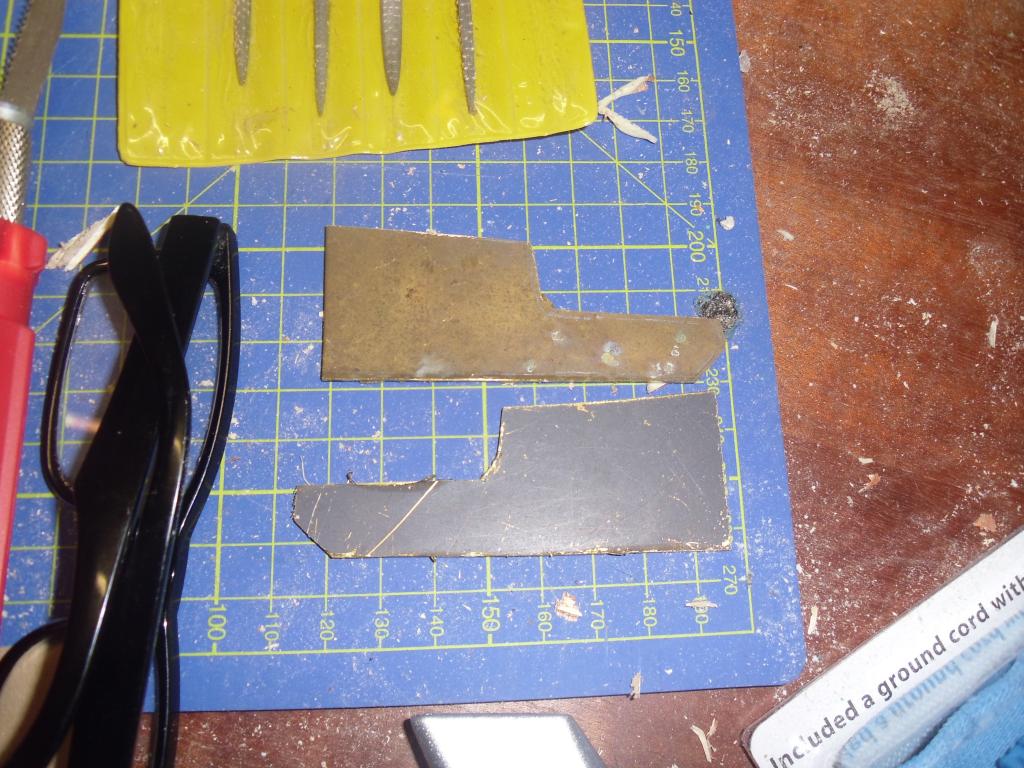

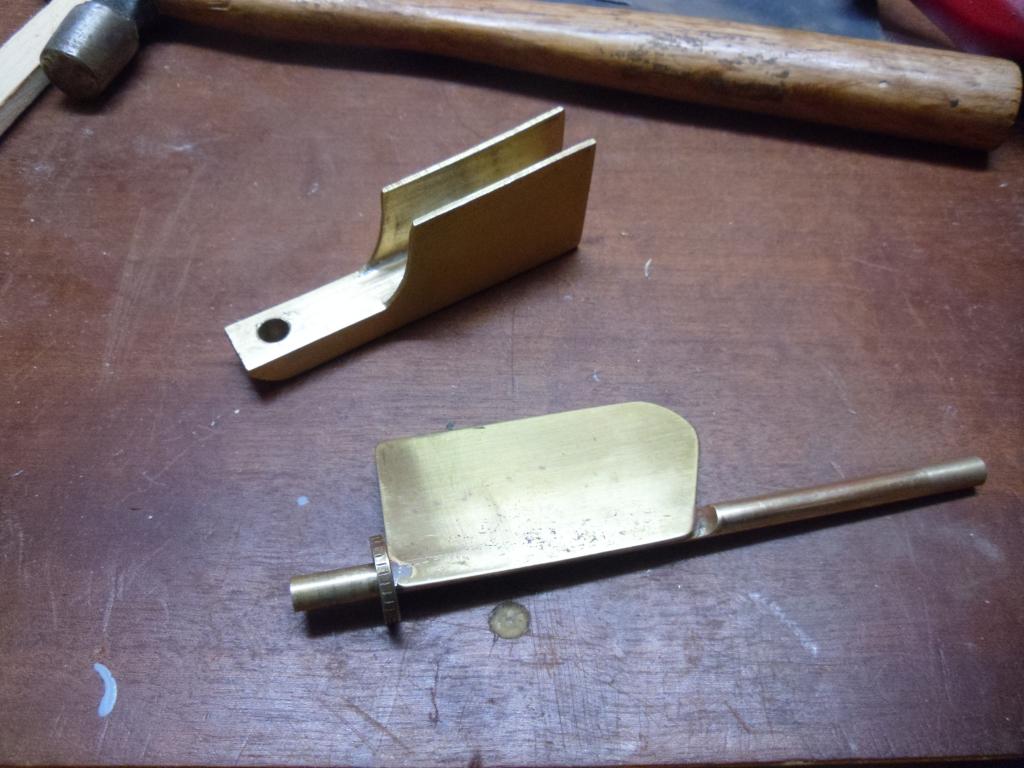

| A little more progress today, fitted the last and smallest bulk head but not glued yet as I need to cut holes in both the centre board and the this bulk head for the rudder post and it's control connections to the servo.  Also I was to strengthen the Skeg I believe it's called, the sticky out bit for the lower end of the rudder post, but have decided to cut away the wooden Skeg and use two brass plates (first photy is them rough cut) and solder a solid piece of bar between them, this will make things easier especially fitting the rudder itself.   Still needs shaping.  Also started making holders for the receiver and the ESC.  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Fri Nov 14, 2014 8:03 pm Fri Nov 14, 2014 8:03 pm | |

| | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Tue Nov 18, 2014 6:49 pm Tue Nov 18, 2014 6:49 pm | |

| Getting the rudder position sorted now, I'll see my friend tomorrow who is to slot the brass rod for me. I have cut removed half the slot for the tube, then placed a bit of ply for strengthening over it, when it's set I will do the other side.  Also roughed out holes for the rudder control rod.  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Nov 20, 2014 5:49 pm Thu Nov 20, 2014 5:49 pm | |

| | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Nov 26, 2014 5:28 pm Wed Nov 26, 2014 5:28 pm | |

| I'm now getting prepared to fit the rudder which I can pick up Friday afternoon  I am replacing the skeg with a brass bar with brass plates soldered to it, made this today and cleaned it up ready. The reason for this move was that I caught the skeg and almost snapped it off, you can see the repair in the first photy.  My efforts in brass and soldering.  Lining it up ready for surgery.  I had to bite the bullet and cut it off.  Then rough out where it was to fit.  One of the many trial fits.  Nice and snug fit.   Now to clear up the mess.   I will drill and screw in place once the rudder is fitted and probably glue or use epoxy resin stuff, not sure quite yet. | |

|

| |

davidjt

Forum Sponsor

Posts : 534

Join date : 2013-01-08

Age : 72

Location : n wales coast

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Nov 27, 2014 3:00 pm Thu Nov 27, 2014 3:00 pm | |

| I would use resin and then screw in, stops any water that might find its way into gaps making a good seal.

david | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Nov 27, 2014 5:36 pm Thu Nov 27, 2014 5:36 pm | |

| I always try to leave it so that I can remove the rudder if necessary. Sometimes that's the only way to remove the propshaft.

barrie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Nov 27, 2014 6:48 pm Thu Nov 27, 2014 6:48 pm | |

| Thanks for your thoughts chaps, Epoxy Resin was my choice but as Barrie says I may need at some point to service the rudder or prop. so I will have to think a bit harder or I might cause a problem. This is the good thing about putting a build blog up, it throws up other folks thoughts and ideas for all to read too  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sat Nov 29, 2014 6:19 pm Sat Nov 29, 2014 6:19 pm | |

| | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sat Nov 29, 2014 8:16 pm Sat Nov 29, 2014 8:16 pm | |

| That's an interesting way of making a rudder. I usually just solder the blade to the shaft with soft solder.  I haven't had one come adrift yet. I have tried silver solder but my torch isn't strong enough for something as big as a rudder. Barrie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sat Nov 29, 2014 11:32 pm Sat Nov 29, 2014 11:32 pm | |

| I had lots of thoughts on this Barrie and this was the decision, a flat surface gives an easier place to solder it, soft solder is what I will use but probably will go silver solder in the future. The little welding set will make it easy for silver soldering and the advantage is that there are several solders with different melting points which I will be using in my copper art projects.

I'm not sure how much it would affect the steer of a boat by putting the rudder on one side of the shaft. Ideally the prop needs to be central to the propeller and I would imagine the longer the boat the more its effect would have, my next one is going to be 54inches long so I think I want to avoid any chance of problems. Perhaps I am being over the top in this, it's just the way I see it. | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sun Dec 07, 2014 8:06 pm Sun Dec 07, 2014 8:06 pm | |

| Been doing a bit on the rudder etc. today and made some progress. First I made the shaft fit and the upper guide tube.  Soldered the two bits of the rudder together.   Then set the tube in epoxy resin.  When it had hardened a little I removed the shaft and put some more epoxy resin around the tube just to make sure, then cleaned some off before it set fully to make things easier.  With the rudder in the loose skeg I thought it a bit low and might bind.  I needed a spacer and couldn't find a suitable non ferrous washer, so I made one from a tube nut (gas pipe fitting).  Newly made washer/spacer in place.   Soon be ready to have a go at the planking  never tackled this job before, so I'll take it slowly and see how it goes. Any tips anyone has would be useful.  | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Mon Dec 08, 2014 5:43 pm Mon Dec 08, 2014 5:43 pm | |

| A little more progress today, I made a lever arm for the rudder. I was going to use a wheel collet but decided against it, when I drilled it out to the size required I didn't think enough thread was left for the grub screw to make proper purchase on the shaft, I had a feeling that the thread might strip. I drilled two opposing holes in the end of the bit of brass left over from the skeg, 3/8square I think, and cut a small suitably sized strip of 2.5mm brass from a sheet I have and soldered them together. Then cleaned it up and cut a slit with a hacksaw through to the second hole turning it into a clamp.  Drilled a few holes.  Here it is with 4mm nut and bolt along with rudder, skeg and all.  | |

|

| |

Guest

Guest

|  Subject: Re: My Eileen Subject: Re: My Eileen  Mon Dec 08, 2014 10:03 pm Mon Dec 08, 2014 10:03 pm | |

| |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sat Dec 13, 2014 11:03 am Sat Dec 13, 2014 11:03 am | |

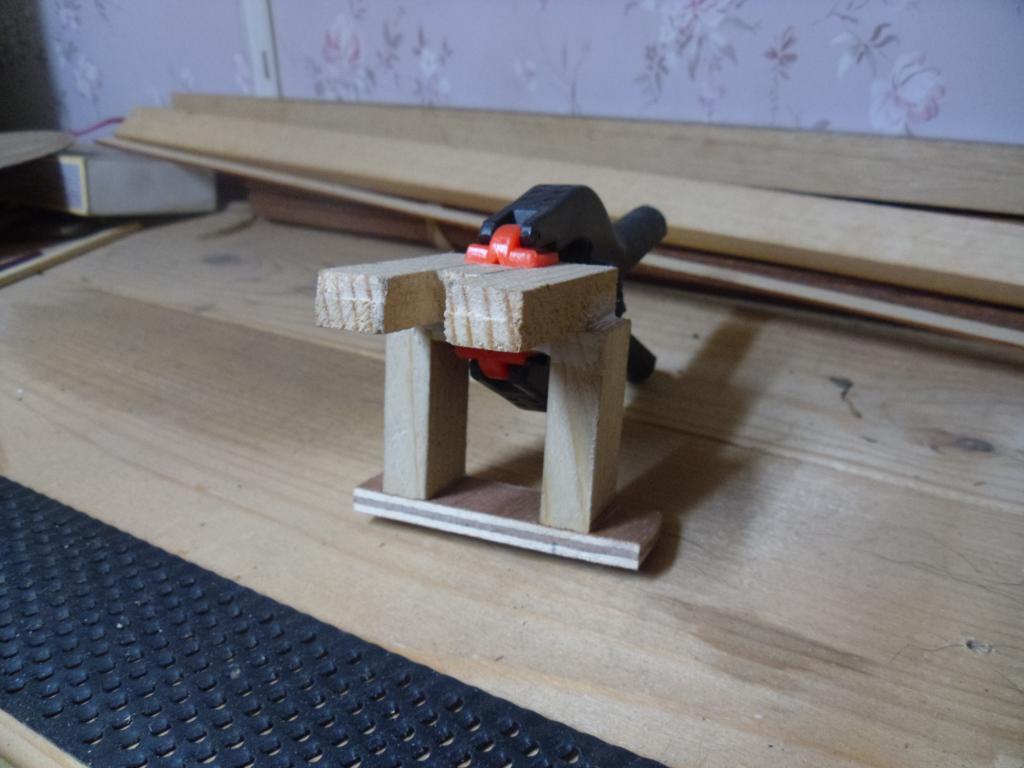

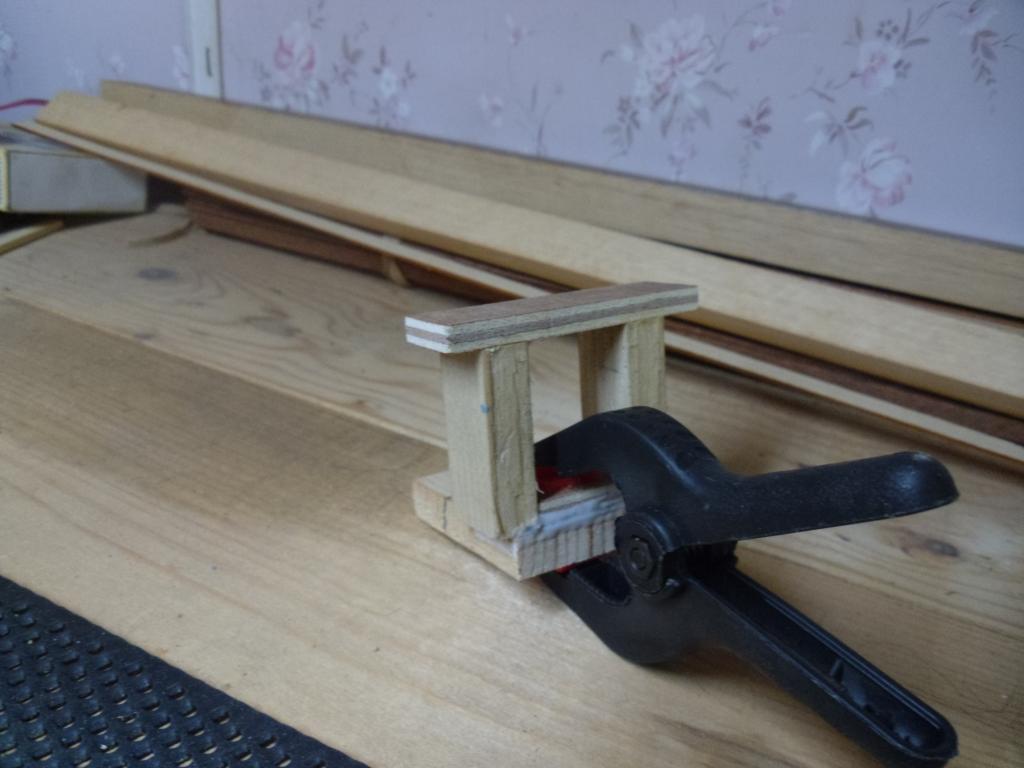

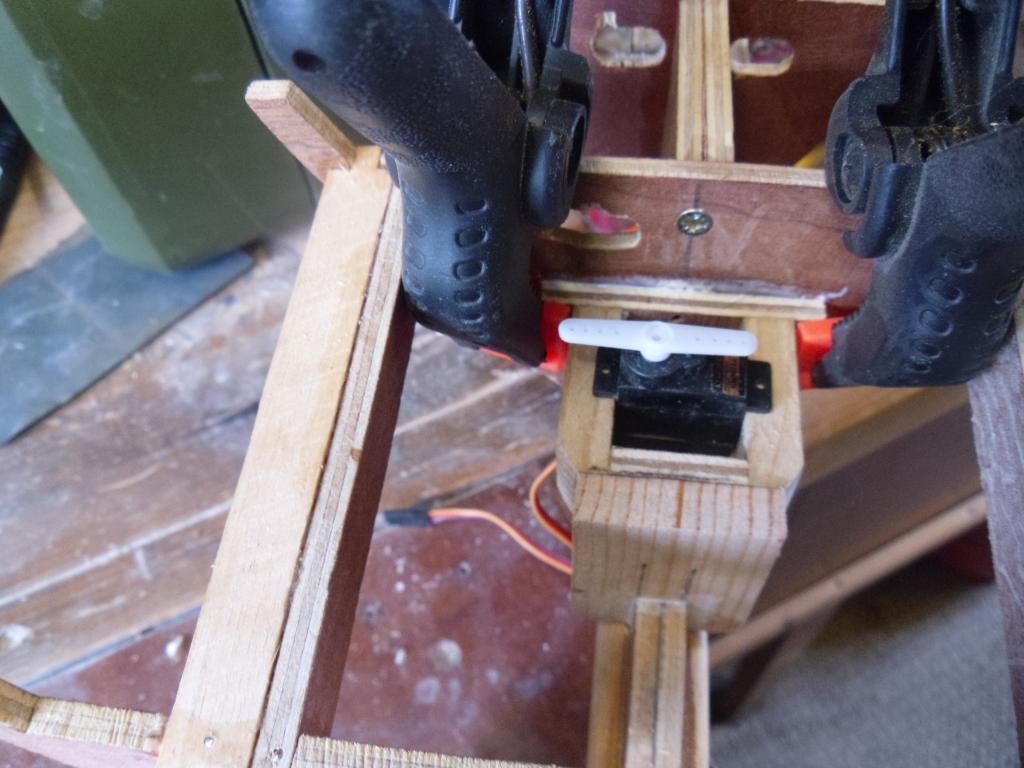

| Did a little more yesterday, I needed to get the rudder and servo link sorted so had to make a mount for the servo. I like these to be adjustable as it makes life easier when making the rod, as long as the rod is somewhere near the length I can then move the servo till it's spot on and central, saves removing that little screw that holds the servo arm for realignment.   Glued and clamped  Servo in place, it can slide in and out to get the correct position.  | |

|

| |

Guest

Guest

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sat Dec 13, 2014 11:37 am Sat Dec 13, 2014 11:37 am | |

| |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sat Dec 13, 2014 12:10 pm Sat Dec 13, 2014 12:10 pm | |

| It just makes things easier Damien, might give others a bit of help too. I get lots of tips on stuff by reading other folks threads, it's a way of giving back.  | |

|

| |

Guest

Guest

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sat Dec 13, 2014 12:34 pm Sat Dec 13, 2014 12:34 pm | |

| That's why we're all here to learn and share this is what makes a successful forum Paul some I don't visit anymore belittle other members that makes for an unfriendly forum this one will never be allowed to go that way. I learned from your trick of a sliding servo adjustment   great Idea I've been modelling for 50yrs and never thought of that, if I can learn something new each day I'm a happy fella.   |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sat Dec 13, 2014 2:05 pm Sat Dec 13, 2014 2:05 pm | |

| I'm pleased if I can help in any small way, it makes the world feel good to be appreciated, thank you  | |

|

| |

Guest

Guest

|  Subject: Re: My Eileen Subject: Re: My Eileen  Sun Dec 14, 2014 1:43 am Sun Dec 14, 2014 1:43 am | |

| |

|

| |

coastie23

Able Seaman

Posts : 38

Join date : 2018-12-12

Location : Whitby Yorks

|  Subject: My Eileen Subject: My Eileen  Wed Dec 12, 2018 7:47 pm Wed Dec 12, 2018 7:47 pm | |

| Did you finish your model if so can we have a update please | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

| |

| |

Guest

Guest

|  Subject: Re: My Eileen Subject: Re: My Eileen  Wed Dec 12, 2018 11:21 pm Wed Dec 12, 2018 11:21 pm | |

| |

|

| |

coastie23

Able Seaman

Posts : 38

Join date : 2018-12-12

Location : Whitby Yorks

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Dec 13, 2018 8:10 am Thu Dec 13, 2018 8:10 am | |

| Morning mate quick question if I may don`t know if you will remember. When you cut out the bulkheads did you have to trims the tops down I`ve traced mine off the plan bulk no1 is 10mm higher than the slope coming off the bow. I noticed yours is flush with the top which is making live difficult to fit the sheer boards broken two (balsa).What thickness ply did you use for the keel and bulk heads at the moment I`m using some spare balsa and to me its going to be very flimsy.

Regards

Coastie

ps nice car. | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: My Eileen Subject: Re: My Eileen  Thu Dec 13, 2018 10:21 pm Thu Dec 13, 2018 10:21 pm | |

| I can't quite remember but it was traced off of the plan as you did. does it look to be in correct alignment with the keel for the planks to fit to ? 1/4inch ply I think, it's all made from scrap wood I had laying around, I love recycling stuff. This car is one of 10 or so that I have, I think I have more projects than time left to live but hey ho I like to keep busy  Have you thought of making a build log (photo log) for others to see, it helps us all as we all do thing a little different and this to me is especially helpful in the my learning curve. | |

|

| |

coastie23

Able Seaman

Posts : 38

Join date : 2018-12-12

Location : Whitby Yorks

|  Subject: Re: My Eileen Subject: Re: My Eileen  Fri Dec 14, 2018 8:57 am Fri Dec 14, 2018 8:57 am | |

| Hi Just trying to work it out at the moment using scrap balsa. now cut 10mm off the top of bulk head 1 so it fits like yours. all bulk heads sit on the plank line just notice I cocked up lol couldnt understand why some of the bulkheads were higher so cut slots in them to get the sheer line to like right (I blame the pills) had bulk head 2 in postion no4 and 3 in 2 4 in 3 will now have to fill in the slots and try again will take a picture and upload it later when i figure how to load pictures. just order 9mm ply for keep and 6 mm for bulk heads marine ply.

Regards

Coastie | |

|

| |

Sponsored content

|  Subject: Re: My Eileen Subject: Re: My Eileen  | |

| |

|

| |

| | My Eileen |  |

|